The Evolving Landscape of Padel Court Technology and Installation

Padel, a rapidly growing racquet sport, has seen an exponential surge in popularity worldwide, driving significant demand for high-quality infrastructure. The modern padel court represents a sophisticated blend of engineering, material science, and design aesthetics, crucial for delivering an optimal player experience and ensuring long-term operational viability. This comprehensive overview delves into the critical aspects of padel court development, from foundational design principles and manufacturing processes to application scenarios and strategic vendor considerations, all tailored for B2B decision-makers and engineering professionals.

Industry Trends and Market Dynamics

The global padel court market is experiencing robust growth, fueled by its accessibility, social appeal, and endorsement by professional athletes. According to industry analysis, the market is projected to grow at a Compound Annual Growth Rate (CAGR) of over 10% from 2023 to 2030, driven by investments in sports infrastructure, particularly in Europe, the Middle East, and Latin America. Key trends include the proliferation of panoramic padel court designs, which offer enhanced spectator visibility and an open aesthetic, and the integration of smart technologies for booking, lighting control, and performance tracking. There's also a rising demand for sustainable and durable materials that minimize environmental impact and reduce maintenance costs over the court's service life. This shift reflects a strategic investment perspective from operators looking for longevity and operational efficiency.

Market Drivers for Padel Court Installations

- Rapid Sport Popularity: Padel's engaging nature and ease of learning attract a wide demographic.

- Investment in Sports Tourism: Resorts and hotels are adding paddle tennis court facilities to enhance guest offerings.

- Commercial Sports Venues: Dedicated padel clubs and multi-sport complexes are expanding their footprint.

- Technological Advancements: Innovations in materials, lighting, and digital management systems.

- Sustainability Focus: Demand for courts built with recycled or eco-friendly components, and energy-efficient lighting.

Technical Specifications and Manufacturing Process

A standard padel court measures 20 meters long by 10 meters wide, enclosed by walls up to 4 meters high. The structural integrity and playability are paramount, demanding precise material selection and manufacturing.

Key Product Materials and Components:

- Structural Frame: Typically galvanized steel (e.g., S235JR or S275JR grades) for corrosion resistance and structural strength. Hot-dip galvanization (EN ISO 1461) ensures superior protection against environmental factors, extending service life significantly.

- Glass Walls: 10mm or 12mm tempered safety glass panels (e.g., conforming to EN 12150-1). These panels undergo a specialized tempering process to enhance impact resistance and, in the event of breakage, shatter into small, blunt pieces for safety.

- Mesh Panels: Electro-welded mesh with specific wire diameters (e.g., 4mm or 5mm) and mesh sizes (e.g., 50x50mm) for ball rebound and spectator visibility. These are also often galvanized and powder-coated.

- Playing Surface: Monofilament or fibrillated synthetic turf, usually 10-12mm pile height, infilled with silica sand. This turf adheres to FIP (International Padel Federation) standards for ball bounce and player traction, offering excellent wear resistance.

- Lighting System: LED floodlights (e.g., 8 units of 200W-300W each) providing optimal illumination (typically 300-500 lux average at playing surface level) with minimal glare and energy consumption.

Manufacturing Process Flow:

- Design and Engineering: CAD/CAM modeling for structural integrity, material optimization, and compliance with FIP regulations. This stage includes finite element analysis (FEA) for stress testing.

- Steel Structure Fabrication:

- Material Sourcing: High-grade steel tubes and profiles.

- Cutting and Shaping: Precision CNC cutting and bending for accurate component dimensions.

- Welding: Robotic or manual welding (e.g., MIG/MAG) following ISO 3834 standards for structural joints.

- Surface Treatment: Hot-dip galvanization to EN ISO 1461, followed by optional electrostatic powder coating for aesthetic finish and enhanced corrosion resistance.

- Glass Panel Production:

- Glass Cutting: Automated precision cutting of float glass.

- Edging and Drilling: CNC machinery for smooth edges and accurate bolt holes.

- Tempering: Heat treatment in a tempering furnace to increase strength up to five times, meeting EN 12150 standards.

- Synthetic Turf Manufacturing: Extrusion of polymer fibers, tufting onto a backing, and application of a latex or polyurethane coating for durability and adhesion.

- Quality Control & Testing: Each component undergoes rigorous inspection. Steel structures are checked for weld integrity and coating thickness; glass panels for temper quality and dimensions; turf for pile height and density. Adherence to ISO 9001 (quality management) and ANSI standards for safety is paramount.

- Packaging and Logistics: Components are carefully packed to prevent damage during transit, ensuring readiness for on-site installation.

The typical service life of a well-maintained padel tennis court structure is 15-20 years, with the playing surface requiring replacement every 5-8 years depending on usage intensity.

Standard Padel Court Specifications

| Parameter |

Specification |

Standard/Reference |

| Court Dimensions (Internal) |

20 m (L) x 10 m (W) |

FIP Regulations |

| Glass Panel Thickness |

10mm or 12mm Tempered Safety Glass |

EN 12150-1 |

| Steel Structure Material |

Galvanized Steel (S235JR / S275JR) |

EN 10025, EN ISO 1461 |

| Synthetic Turf Pile Height |

10-12 mm |

FIP Approved |

| Lighting (Average Lux) |

300-500 Lux (LED) |

Sport Lighting Standards |

| Net Height (Middle) |

0.88 meters |

FIP Regulations |

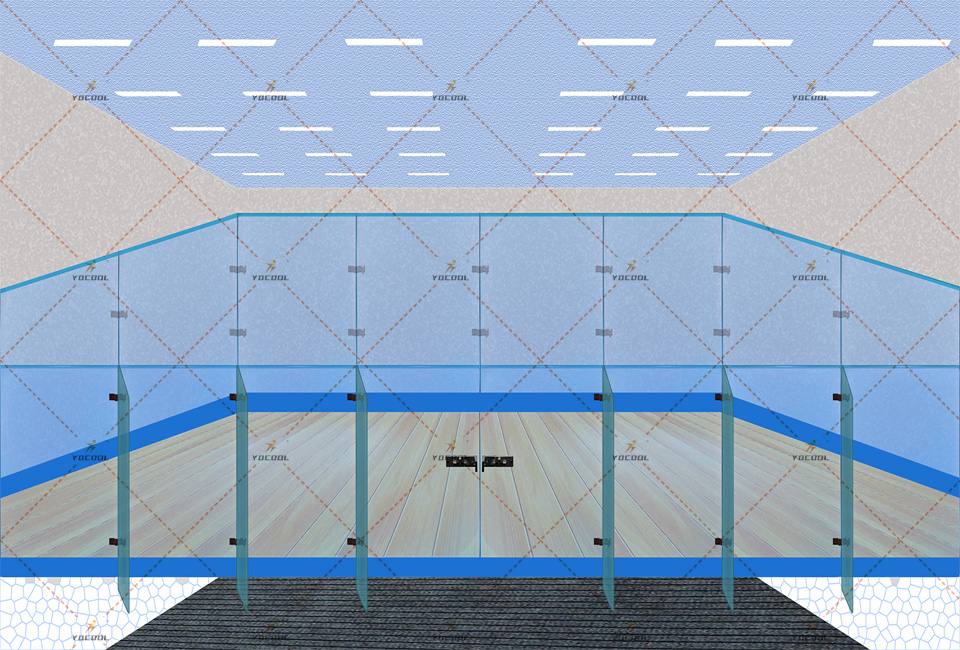

Figure 1: Illustration of a modern panoramic padel court design.

Figure 1: Illustration of a modern panoramic padel court design.

Application Scenarios and Target Industries

The versatility of the paddle court makes it suitable for diverse commercial and recreational applications.

- Sports & Leisure Centers: Dedicated padel clubs, multi-sport complexes, and fitness centers integrate padel courts to diversify offerings and attract new members.

- Hospitality & Tourism: Luxury hotels, resorts, and cruise lines install courts as premium amenities, enhancing guest experience and generating additional revenue.

- Residential & Commercial Developments: High-end residential communities, corporate campuses, and large commercial centers provide courts as part of their recreational infrastructure, boosting property value and tenant satisfaction.

- Educational Institutions: Universities and schools are adding padel facilities to promote physical activity and expand their sports programs.

- Private Installations: High-net-worth individuals or exclusive clubs opting for bespoke designs for private use.

In these scenarios, advantages like robust construction ensure minimal downtime, energy-efficient LED lighting reduces operational costs, and the aesthetic appeal of a panoramic padel court enhances the overall ambiance of the facility.

Technical Advantages and Performance Metrics

Investing in a professionally engineered padel tennis court offers distinct technical advantages critical for B2B operators.

- Superior Durability: Galvanized and powder-coated steel structures provide exceptional resistance to corrosion, UV radiation, and mechanical stress. Tempered glass panels withstand impacts from paddle racquet strikes and player contact, crucial for safety and longevity.

- Optimized Playability: High-density synthetic turf with silica sand infill ensures consistent ball bounce, optimal grip for players, and reduced risk of injury. The precise rebound of the glass and mesh walls creates dynamic gameplay.

- Low Maintenance Requirements: Modern materials and construction techniques reduce the need for frequent repairs. The synthetic turf requires periodic brushing and infill management, while steel and glass components are virtually maintenance-free beyond routine cleaning.

- Enhanced Safety Features: Rounded edges on steel components, anti-slip court surfaces, and shatter-resistant glass are standard, complying with international safety regulations.

- Energy Efficiency: State-of-the-art LED lighting systems significantly reduce electricity consumption compared to traditional halide lamps, offering substantial operational savings.

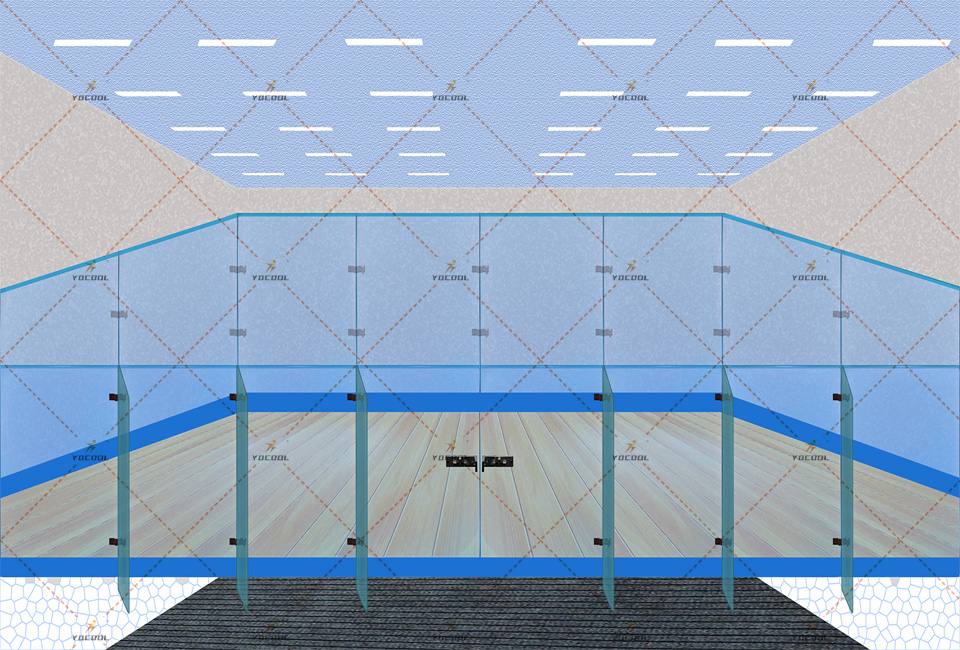

Figure 2: Close-up of a high-quality padel court playing surface and wall structure.

Figure 2: Close-up of a high-quality padel court playing surface and wall structure.

Vendor Comparison: Selecting the Right Padel Court Partner

Choosing a reputable vendor for your paddle court project is crucial for ensuring quality, compliance, and long-term value. Key differentiators include material quality, design innovation, certification, and after-sales support.

Padel Court Vendor Comparison Table (Illustrative)

| Feature/Vendor |

Vendor A (Premium) |

Vendor B (Standard) |

Vendor C (Budget) |

| Structural Steel |

Hot-Dip Galvanized S275JR, Powder Coated |

Electro-Galvanized S235JR, Powder Coated |

Pre-Galvanized Steel, Painted |

| Glass Thickness |

12mm Tempered (EN 12150) |

10mm Tempered (EN 12150) |

8mm Tempered |

| Playing Surface (Turf) |

Monofilament 12mm, FIP Certified |

Fibrillated 10mm, FIP Compliant |

Basic Fibrillated 10mm |

| Lighting System |

8x300W LED (500 Lux avg.) |

8x200W LED (350 Lux avg.) |

4x400W Halide (250 Lux avg.) |

| Warranty (Structure) |

15 Years |

10 Years |

5 Years |

| Certification |

ISO 9001, FIP Endorsed |

ISO 9001 |

CE Mark |

Customized Solutions and Design Flexibility

Modern padel court manufacturers offer extensive customization options to meet specific client requirements, site conditions, and branding guidelines. This flexibility ensures that each installation is uniquely tailored to its environment and purpose.

Areas of Customization:

- Structural Design: Options for traditional, semi-panoramic, or panoramic configurations. Custom colors for steel structures via powder coating.

- Glass Panels: Tinted or frosted glass for privacy or aesthetic preference. Custom branding or logos can be applied.

- Playing Surface: Various turf colors (blue, green, black) and fiber types (monofilament for high performance, fibrillated for durability).

- Lighting: Advanced LED systems with dimming capabilities, smart controls, and integration with facility management systems.

- Accessories: Integrated scoreboards, custom spectator seating, access control systems, and surrounding landscaping elements.

- Foundation Solutions: Adaptable designs for different ground conditions, including options for portable or semi-permanent installations.

The ability to adapt designs to specific architectural contexts or branding requirements is a significant advantage for commercial entities seeking to differentiate their offerings.

Application Case Studies and Customer Experience

Real-world applications demonstrate the tangible benefits of well-executed padel court projects.

Case Study 1: Luxury Resort Development (Dubai, UAE)

- Challenge: A prominent luxury resort sought to add high-end sporting facilities to attract international tourists and enhance guest retention. They required two panoramic padel courts that could withstand extreme desert temperatures and salt air.

- Solution: Installation of two custom panoramic courts featuring marine-grade hot-dip galvanized and special anti-corrosion powder-coated steel structures, 12mm tempered safety glass, and UV-resistant monofilament turf. Advanced LED lighting was integrated with smart control systems.

- Outcome: The courts became a major attraction, with booking rates consistently over 80%. Guest feedback highlighted the superior playing conditions and aesthetic integration with the resort's luxury branding. The robust construction ensured minimal maintenance despite harsh environmental conditions. The resort reported a 15% increase in sports amenity revenue within the first year.

Case Study 2: Urban Sports Club Renovation (Barcelona, Spain)

- Challenge: An established urban tennis club aimed to diversify its offerings by converting underutilized tennis courts into multiple paddle courts to tap into the booming local padel market. Space optimization and quick installation were key.

- Solution: Four semi-panoramic padel courts were installed, utilizing a modular design for efficient setup. The court's foundation was adapted to existing concrete slabs, minimizing civil work. Energy-efficient LED lighting was crucial for evening play and reduced operational costs.

- Outcome: The club saw a significant surge in new memberships, with the padel courts frequently booked throughout the day and evening. Member satisfaction increased, citing the excellent court quality and vibrant atmosphere. The rapid installation minimized disruption to existing club operations.

Figure 3: Padel courts integrated into a commercial sports complex.

Figure 3: Padel courts integrated into a commercial sports complex.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ)

- Q1: What is the typical installation time for a standard padel court?

- A1: On average, a single court can be installed in 5-7 working days, assuming the concrete foundation is already prepared and cured. Multiple courts will naturally extend this timeline.

- Q2: What maintenance is required for a paddle court?

- A2: Routine maintenance includes brushing the turf to redistribute sand infill, checking for debris, and cleaning glass panels. Periodic deep cleaning and infill top-ups are recommended every 12-18 months, depending on usage.

- Q3: Can padel courts be installed outdoors and indoors?

- A3: Yes, our courts are designed for both indoor and outdoor environments. Outdoor courts feature enhanced corrosion protection and UV-resistant materials. Indoor courts benefit from climate-controlled settings for consistent play.

- Q4: Are your courts compliant with FIP regulations?

- A4: Absolutely. All our padel court designs strictly adhere to the official dimensions and material specifications set forth by the International Padel Federation (FIP) to ensure professional playability.

Lead Time and Fulfillment

Our streamlined manufacturing and logistics ensure efficient project delivery. Standard padel court components typically have a production lead time of 4-6 weeks from order confirmation. Shipping durations vary based on destination but generally range from 2-4 weeks for international freight. Project management includes detailed planning, on-site supervision (if required), and coordination with local contractors to ensure timely and successful installation. For large-scale or customized projects, a detailed project timeline will be provided upon scope definition.

Warranty Commitments

We stand by the quality and durability of our products. All our padel court steel structures come with a 15-year warranty against manufacturing defects and structural integrity issues. Glass panels are covered by a 5-year warranty against spontaneous breakage (excluding impact damage), and synthetic turf carries a 5-8 year warranty, depending on the product type and usage conditions. Our warranty ensures peace of mind and protects your investment.

Customer Support and After-Sales Service

Our commitment extends beyond installation. We provide comprehensive after-sales support, including spare parts availability, technical assistance, and guidance on maintenance best practices. Our dedicated support team is available via phone and email during business hours to address any queries or concerns. For complex issues, we offer on-site consultation and repair services to minimize downtime and ensure continuous operation of your paddle tennis court facilities.

Figure 4: Detailed view of padel court net and support structure.

Figure 4: Detailed view of padel court net and support structure.

Conclusion

The strategic investment in a high-quality padel court offers significant returns for B2B enterprises in sports, hospitality, and real estate sectors. By understanding the intricate technical specifications, rigorous manufacturing processes, and comprehensive support systems, decision-makers can procure solutions that are not only aesthetically pleasing but also deliver superior performance, unparalleled durability, and long-term operational efficiency. Partnering with an expert provider ensures adherence to international standards, customized design flexibility, and reliable after-sales service, positioning your facility at the forefront of the burgeoning global padel market.

References

- FIP – International Padel Federation Official Rules. Available at: www.padelfip.com

- ISO 9001:2015 Quality management systems – Requirements. International Organization for Standardization.

- EN 12150-1:2015 Glass in building – Thermally toughened soda lime silicate safety glass – Part 1: Definition and description. European Committee for Standardization.

- EN ISO 1461:2022 Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods. International Organization for Standardization.

- Sports Industry Market Research Reports. Various industry market analysis platforms.

Figure 1: Illustration of a modern panoramic padel court design.

Figure 1: Illustration of a modern panoramic padel court design.

Figure 2: Close-up of a high-quality padel court playing surface and wall structure.

Figure 2: Close-up of a high-quality padel court playing surface and wall structure.

Figure 3: Padel courts integrated into a commercial sports complex.

Figure 3: Padel courts integrated into a commercial sports complex.

Figure 4: Detailed view of padel court net and support structure.

Figure 4: Detailed view of padel court net and support structure.