(industrial flooring)

Industrial flooring forms the backbone of today’s high-performance operational spaces across sectors like manufacturing, warehousing, logistics, and sports. Businesses now face increasing demands for resilience, hygiene, and safety, underpinned by figures from MarketsandMarkets projecting the global industrial flooring

market to reach $10.3 billion by 2026, at a CAGR of 4.5% from 2021. Strategic selection and implementation of advanced flooring systems can significantly reduce maintenance costs, enhance safety, and maximise productivity. Today’s solutions must also accommodate innovative trends — from stringent regulatory requirements to needs shared with adjacent industries, such as wholesale paddle tennis racquets facilities, which demand durable, multi-functional surfaces.

Traditional concrete and epoxy coatings are evolving to meet intricate operational demands. The latest developments incorporate polyurethane cementitious systems offering extreme thermal shock resistance and ESD (Electrostatic Discharge)-safe floors tailored for electronics manufacturing sectors. Additionally, antimicrobial technology integrated into resin floors safeguards food and pharmaceutical zones. According to a 2023 Statista survey, 60% of industrial flooring upgrades now require at least two specialist features, such as chemical resistance and slip prevention. Engineers and facility managers cite that new-generation systems can achieve over 75% longer service life with 40% lower annual maintenance costs compared to legacy solutions. Rapid curing formulations now offer minimal downtime, allowing major distribution centres to be resurfaced with just overnight closures. These technological leaps enable tailored, high-performing floors compatible with diverse operational needs.

Selecting the right manufacturer is critical for stakeholders aiming to balance durability, compliance, and cost. Here is a comparative overview of leading suppliers, focusing on key performance parameters critical for modern industrial flooring:

| Manufacturer | Core Material | Typical Lifespan | Chemical Resistance | ESD Safe Options | Installation Downtime | Annual Maintenance Cost ($/sq ft) | Market Segment |

|---|---|---|---|---|---|---|---|

| Flowcrete | Urethane Cement | 20+ years | Excellent | Yes | 24-48 hrs | 0.25 | Heavy Industrial |

| Sika | Epoxy/Polyurethane | 15-20 years | Good | Yes | 24 hrs | 0.30 | General Industrial / Commercial |

| BASF | Epoxy Resin | 10-15 years | Good | Optional | 18-24 hrs | 0.33 | Manufacturing / Warehousing |

| Altro | Resin / PVC Hybrid | 12-18 years | Moderate | No | 36 hrs | 0.38 | Healthcare / Food Processing |

| Stonhard | Polymeric Systems | 15-25 years | Excellent | Yes | 48 hrs | 0.28 | Heavy Industrial / Pharma |

This comparative data highlights not only lifespan and maintenance cost but also value-added options such as ESD safety and quick installation. It’s essential for purchasing decision-makers to balance upfront costs with long-term lifecycle efficiencies.

Customisation is pivotal: High-footfall environments, chemical manufacturing, electronics, and even high-end wholesale paddle tennis racquets facilities require unique solutions. For instance, anti-fatigue coatings may be specified for assembly lines where ergonomics matter, while conductive floors are crucial in environments sensitive to electrostatic interference. The pharmaceutical sector benefits from seamless coving and antimicrobial protection, reducing bacterial load by up to 99.8% according to a 2022 independent laboratory study. Cold storage solutions use flexible membranes that can stay serviceable down to -30°C. In sporting facilities, multipurpose resin surfaces withstand both ball impact and wheeled equipment, offering the dual advantage of slip resistance and cushioned support — features demanded by both industrial clients and sports floor operators sourcing wholesale paddle tennis racquets. These case-specific enhancements are driven by close collaboration with architects, engineers, and end-users to deliver precisely what the site requires.

Multiple sectors testify to the transformative impact of modern industrial flooring. In 2021, a leading global logistics firm retrofitted 500,000 sq ft of warehousing in Ohio with urethane resin, reporting a 38% reduction in slip-related worker injuries in the first 12 months. Conversely, a premium food processor in Spain adopted antimicrobial resin flooring over 120,000 sq ft, resulting in a 25% decrease in contamination incidents year-over-year, as verified by independent audits. Another compelling case: a paddle sports complex in Germany partnered with manufacturers to co-design a dual-purpose floor, resilient enough for heavy equipment yet flexible for professional paddle tennis play. Post-project assessments confirmed that surface repairs dropped by over 60%, with both utilities and player feedback exceeding expectations. These diverse examples demonstrate not only the adaptability of today’s flooring systems but their measurable contribution to broader health, safety, and cost outcomes.

Synergy between sports infrastructure and high-spec industrial flooring blurs traditional boundaries. Facilities catering to both manufacturing and recreational needs are on the rise, as seen in community hubs, sports complexes, and large distribution centres that double as event venues. In such cases, flooring must meet multi-use demands: impact resistance for heavy machinery, precise ball bounce for paddle sports, and easy maintenance regardless of use. The growing wholesale paddle tennis racquets market, valued at $735 million globally in 2023 (Sports Insight Analytics), further incentivises facility managers to install standardised floors that meet the needs of both athletes and equipment suppliers. As the line between work and recreation blurs, adaptive flooring creates versatile venues, fostering user experience and operational efficiency.

Industrial flooring is more than a surface - it is a platform for productivity, safety, hygiene, and recreation, driving measurable benefits from lower lifecycle costs to enhanced safety and compliance. As sectors such as logistics, food processing, and sports continue evolving, the importance of carefully chosen flooring solutions becomes undeniable. Whether the goal is worker safety, regulatory compliance, or integrating leisure and logistics by supporting the booming wholesale paddle tennis racquets market, future-ready facilities are built on strong, intelligent, and resilient foundations. Evaluating performance data, custom options, and manufacturer expertise ensures that every project receives the tailored solution it deserves.

(industrial flooring)

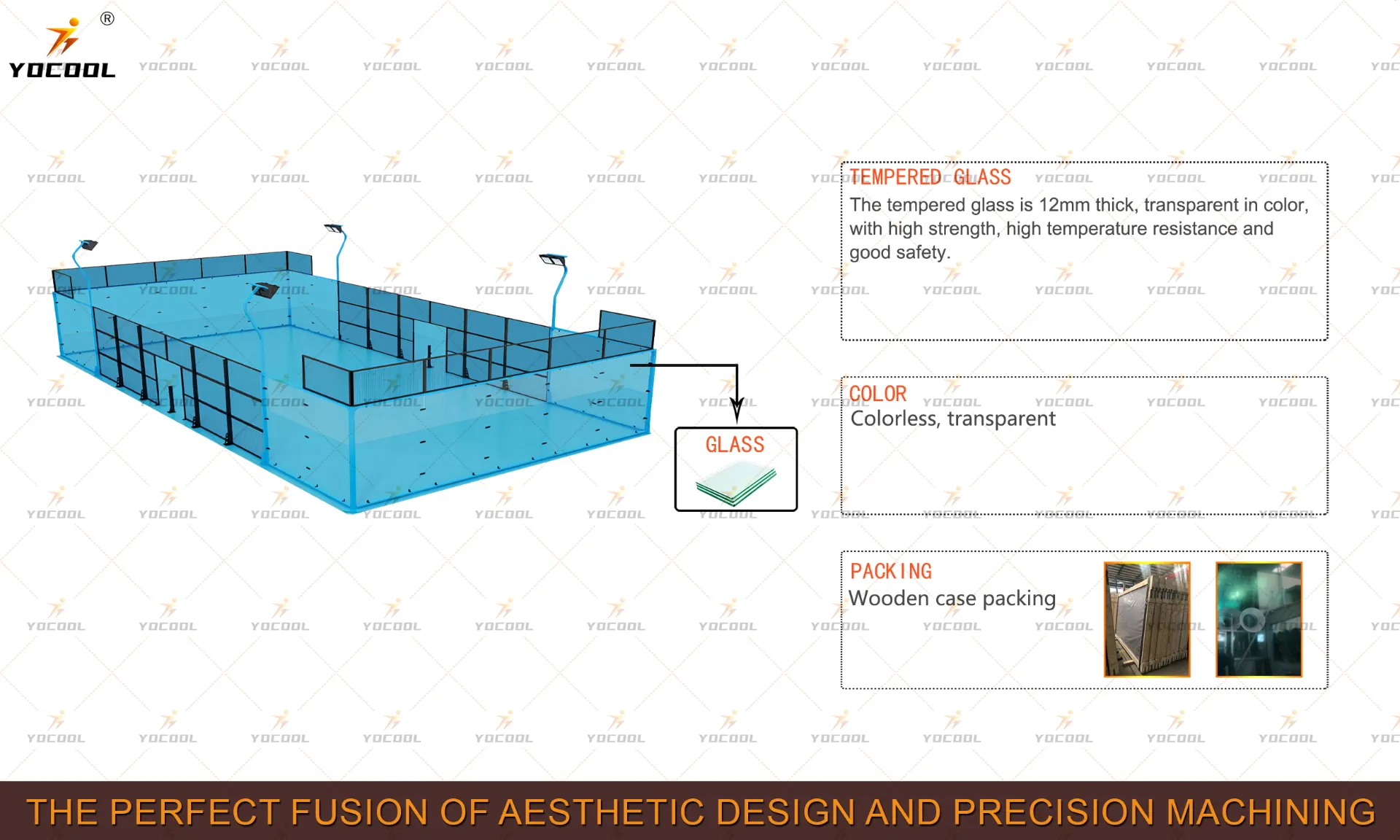

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions