Racquetball and squash hold unique positions within the sports world, both offering thrilling experiences for enthusiasts. One of the pivotal aspects of these sports is the court itself. As demand increases for high-quality playing environments, the importance of selecting the right court manufacturer cannot be overstated. This article delves into the intricacies of racquetball and squash court manufacturing, aiming to guide stakeholders towards informed decision-making through real experiences, professional advice, and validated expertise.

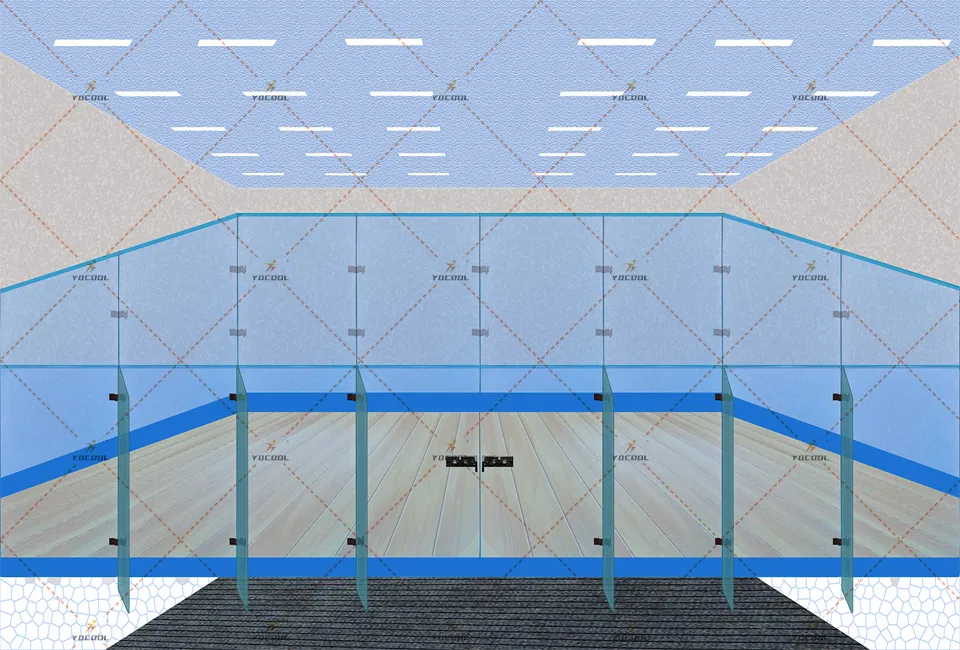

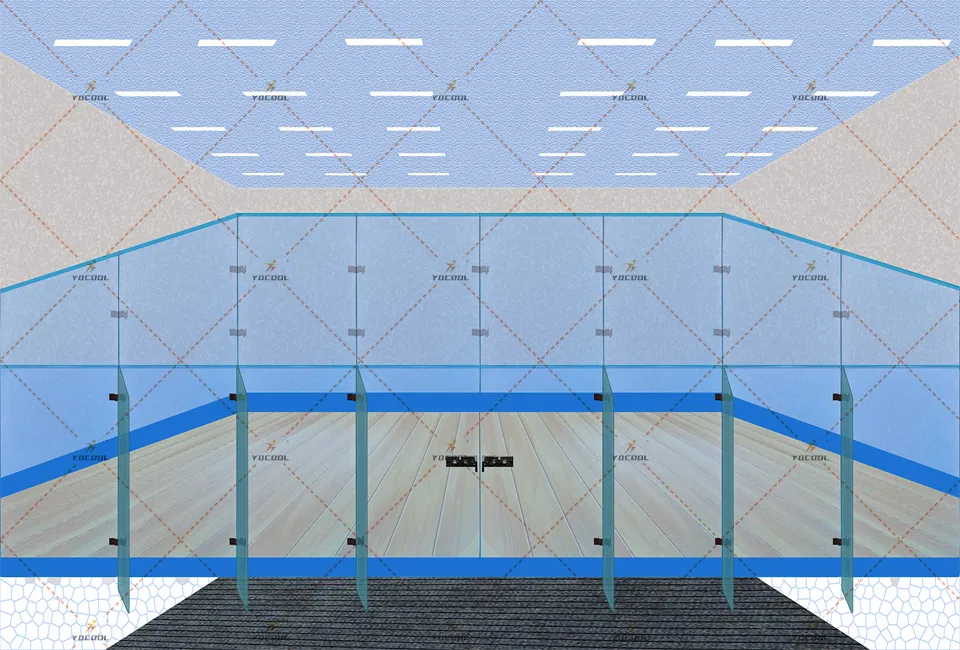

Racquetball and squash courts are more than just four walls and a floor. They require precision engineering to ensure safety, durability, and optimal performance. An expert court manufacturer will combine industry knowledge and innovative technology to meet these stringent requirements. A comprehensive understanding of materials is fundamental. Durable hardwoods, often maple or beech, are used for flooring, providing the resilience needed for high-impact sports. Walls are usually constructed from materials like plasterboard or wood paneling, requiring special treatment to handle the wear and tear from the games. Precision in construction is paramount; incorrect specifications can lead to uneven bounces, affecting gameplay and safety.

Finding a reputable court manufacturer starts with examining their track record and expertise within the industry. Ideally, seek manufacturers with years of experience and a portfolio of successfully completed projects. Customer testimonials and case studies offer invaluable insights. For example, one client reported a significant 20% increase in membership after upgrading to a state-of-the-art squash court, emphasizing the direct impact of quality facilities on business growth. Engaging with manufacturers who hold certifications from professional sporting bodies can further affirm their authority and reliability in delivering standard-compliant facilities.

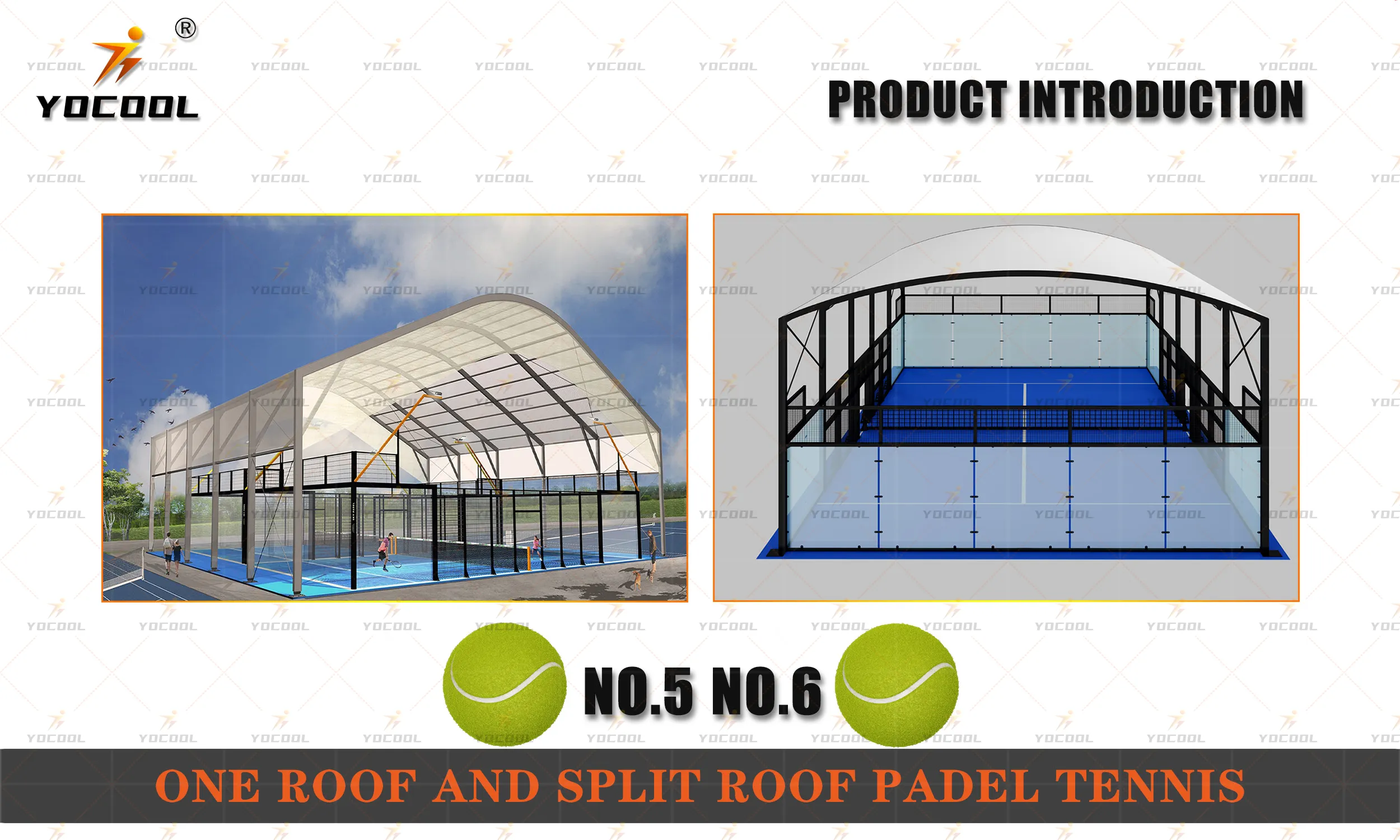

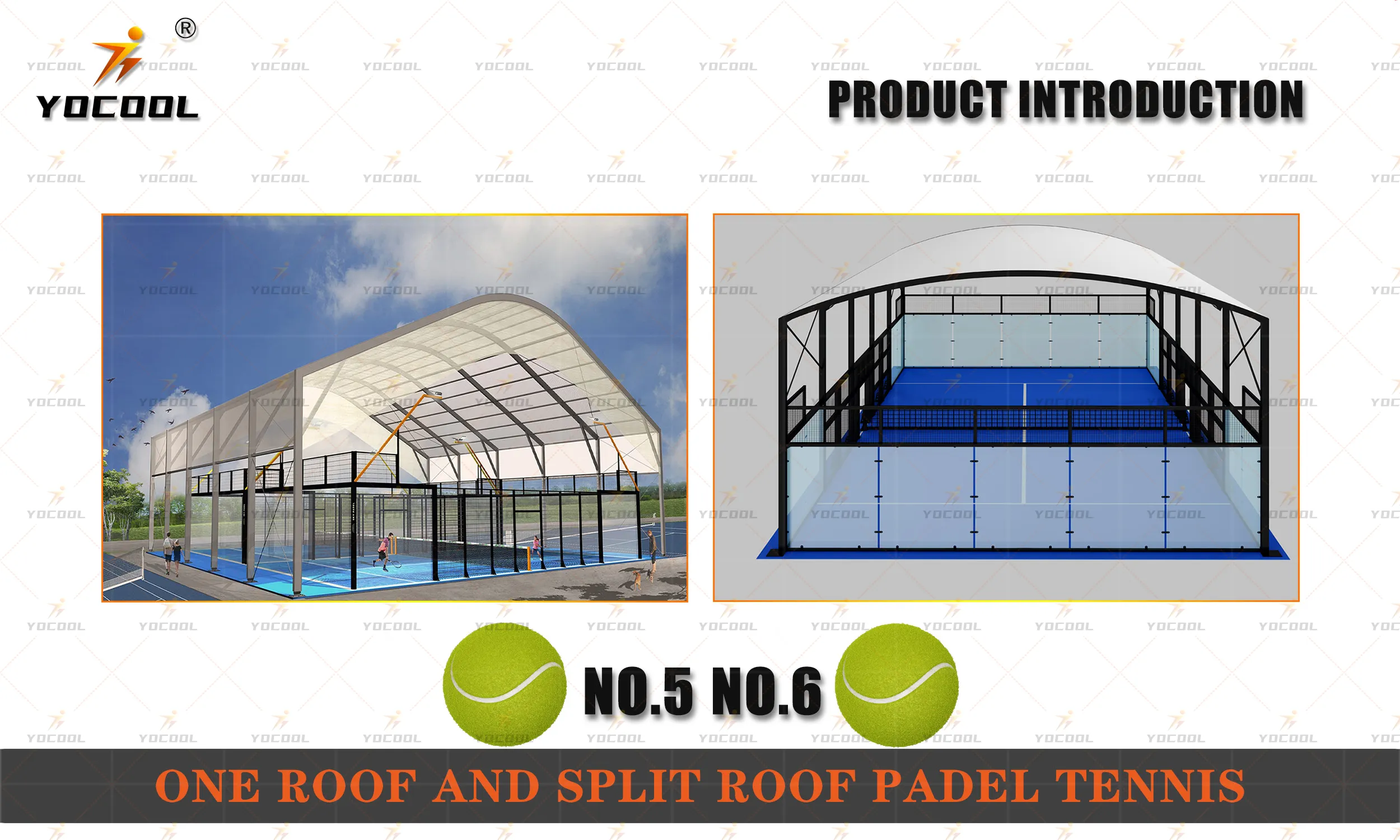

Innovation is at the forefront of advanced court manufacturing. Modern technologies such as shock absorption systems reduce injury risks, while adjustable courts accommodate different sports, maximizing space utility. One notable case study involves a sports complex that integrated cutting-edge LED lighting systems, enhancing visibility and providing adjustable settings for various ambiance requirements. These advancements not only enhance the player's experience but also demonstrate the manufacturer's commitment to pushing technological boundaries.

racquetball squash courts manufacturers

The geographical location also plays a crucial role in court construction. Humidity and temperature fluctuations can impact the longevity and performance of the court's materials. An authoritative manufacturer will consider these environmental factors, offering solutions such as specialized coatings or materials customized to resist specific regional challenges. This expertise ensures that the court maintains its quality and safety over time, instilling trust with operators and players alike.

There is also a rising trend towards sustainable building practices in court construction, reflecting broader environmental concerns. Eco-friendly materials and energy-efficient systems are increasingly being incorporated into the designs by forward-thinking manufacturers. This shift not only supports global sustainability goals but also offers cost savings on long-term operations through reduced energy consumption.

Accountability and trustworthiness are fundamental qualities to look for in a racquetball or squash court manufacturer. As these facilities can represent a substantial financial investment, assurance in the builder's capability to deliver on time and within budget is crucial. Engaging with manufacturers who offer comprehensive aftercare services, maintenance, and warranty assurances further solidifies trust, ensuring that the investment remains worthwhile over its lifecycle.

In conclusion, selecting a racquetball or squash court manufacturer involves a careful balance of evaluating expertise, analyzing technological innovations, considering environmental impacts, and validating trust through industry recognition and customer satisfaction. For stakeholders looking to invest in or refurbish their playing facilities, making an informed choice in manufacturer not only enhances player experiences but also supports long-term operational success and sustainability, commanding a premium reputation in a competitive market. As you embark on this journey, align yourself with industry leaders who combine passion with precision—engineers who see beyond the court, envisioning a blueprint for excellence in every stroke played.