The global sports infrastructure landscape is undergoing a significant transformation, with the padel court emerging as a dominant trend, particularly within commercial and private recreational sectors. Originating in Mexico, padel has rapidly expanded across Europe, notably in Spain, France, Italy, and Sweden, before gaining substantial traction in the Middle East, North America, and parts of Asia. This explosive growth is driven by its accessibility, social nature, and dynamic gameplay, making it an attractive investment for sports clubs, residential developers, luxury resorts, and even private individuals. The demand for high-quality, durable, and aesthetically pleasing padel tennis court facilities has consequently soared, prompting manufacturers to innovate in design, materials, and construction methodologies. Modern padel courts are not merely playing surfaces; they are sophisticated engineered structures designed to withstand diverse climatic conditions, high usage rates, and stringent performance demands. Understanding the intricate details of their construction, from foundational elements to the final playing surface, is crucial for stakeholders looking to invest in or develop such facilities. This strategic investment in padel infrastructure directly contributes to enhancing community health, fostering social interaction, and delivering significant return on investment for commercial entities through membership growth and facility utilization. The market trend indicates a clear shift towards premium, customizable solutions that integrate advanced materials and smart technologies, ensuring longevity, minimal maintenance, and superior player experience. This evolution underscores the importance of partnering with manufacturers who demonstrate a deep understanding of both the sport's unique requirements and the technical complexities of large-scale, high-performance sports construction.

The robust expansion of the global padel court market is also influenced by several macro-economic factors and evolving consumer preferences. An increasing awareness of health and wellness, coupled with the desire for social activities that bridge generational gaps, positions padel as an ideal sport. Investment flows from venture capital firms into dedicated padel clubs and infrastructure development companies highlight the perceived lucrative nature of this sector. Furthermore, technological advancements in material science have significantly contributed to the enhanced performance and durability of modern paddle court systems. For instance, the development of specialized tempered glass for court walls and advanced artificial turf for playing surfaces ensures optimal ball bounce, player safety, and reduced wear and tear. The shift towards sustainable and eco-friendly manufacturing processes also represents a key industry trend, with manufacturers exploring recycled materials and energy-efficient production methods to minimize environmental impact. This holistic approach, encompassing both performance and ecological responsibility, resonates strongly with contemporary B2B clients who prioritize long-term value and corporate social responsibility. The meticulous planning and execution required for a successful panoramic padel court project demand a comprehensive understanding of site-specific conditions, regulatory compliance, and a commitment to precision engineering. As such, the selection of a manufacturing partner extends beyond mere product procurement; it involves securing a comprehensive solution provider capable of delivering projects that meet international standards and exceed client expectations, ensuring the longevity and popularity of the installed facilities.

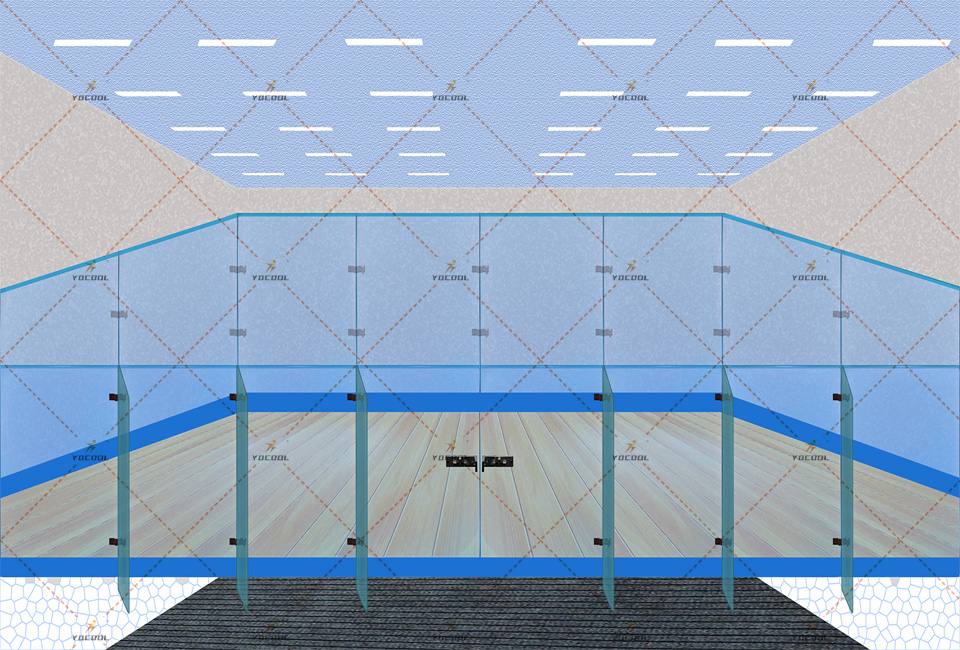

The construction of a high-performance padel court is a complex process demanding precision engineering and adherence to rigorous quality standards, ensuring both player safety and structural longevity. The core materials typically include robust galvanized steel for the main frame structures, high-strength tempered glass panels for the walls, and specialized artificial turf for the playing surface. The manufacturing process begins with the precise cutting and fabrication of steel profiles, often utilizing advanced CNC (Computer Numerical Control) machining to achieve exact dimensions and tight tolerances for seamless assembly. Following fabrication, the steel components undergo a hot-dip galvanization process, adhering to international standards like ISO 1461, which provides superior corrosion resistance crucial for outdoor installations and extending the product’s service life, often exceeding 20-25 years with proper maintenance. This is followed by an electrostatic powder coating process, which not only enhances aesthetic appeal but also adds an additional layer of protection against environmental elements, ensuring the court's structural integrity even in harsh climates found in coastal or high-humidity regions. For the glass elements, typically 10mm or 12mm thick tempered safety glass is used, manufactured to meet specific impact resistance standards such as ANSI Z97.1 or EN 12150-1, guaranteeing player safety upon impact. These glass panels are processed through specialized tempering furnaces, where controlled heating and rapid cooling create internal stresses that dramatically increase strength, making them several times stronger than annealed glass.

Beyond the structural components, the playing surface, typically a specific type of artificial turf, plays a pivotal role in the gameplay experience of a paddle tennis court. The turf itself is manufactured from specialized polymers designed for durability, consistent ball bounce, and optimal grip, often featuring monofilament or fibrillated fibers. The installation process of the turf requires meticulous attention to detail, including proper sub-base preparation for optimal drainage, precise seaming, and the application of infill materials (like silica sand) to ensure stability, reduce friction, and enhance playability. Quality control throughout the entire manufacturing and installation cycle is paramount. Comprehensive testing protocols, in line with ISO 9001 for quality management systems, are implemented at every stage, from raw material inspection to final product assembly and performance validation. This includes material composition analysis, dimensional accuracy checks, weld integrity testing, and surface hardness assessments. For example, the load-bearing capacity of structural components is verified through stress tests, and the integrity of glass panels is confirmed by impact tests simulating real-world playing conditions. The meticulous application of these manufacturing and inspection standards ensures that the final padel court system is not only aesthetically pleasing but also a highly functional, safe, and exceptionally durable investment suitable for high-traffic environments like commercial sports complexes, community recreational centers, and private residential estates, delivering long-term value and superior performance.

Understanding the technical parameters of a padel court is crucial for ensuring optimal performance, longevity, and adherence to international playing standards set by organizations like the International Padel Federation (FIP). A standard court measures 20 meters long by 10 meters wide, enclosed by walls typically 3 to 4 meters high. The materials used, as detailed previously, directly influence key performance indicators. For instance, the tempered glass walls, generally 10mm or 12mm thick, are selected for their clarity, impact resistance, and ability to provide a consistent ball bounce, which is fundamental to the game's strategy. The steel structure, usually consisting of electro-welded mesh and tubular profiles, must be engineered to withstand lateral forces exerted during play, ensuring structural stability. Lighting is another critical parameter, with professional courts typically requiring 200-300 lux for recreational play and up to 500-700 lux for professional competitions, achieved through high-efficiency LED floodlights strategically placed to minimize shadows and glare. The artificial turf, often Blue, Green, or Terra Cotta in color, is specified by pile height (typically 10-15mm) and yarn density, which affects ball speed and player grip. Maintenance requirements are significantly reduced due to these robust material specifications, resulting in lower operational costs over the court's lifespan. These meticulously engineered specifications not only enhance player experience by providing optimal playing conditions but also guarantee the court's structural integrity and safety for decades, making them a wise investment for high-utilization commercial facilities.

| Parameter | Specification | Standard/Reference |

|---|---|---|

| Court Dimensions | 20m (L) x 10m (W) | FIP Regulation |

| Glass Wall Thickness | 10mm or 12mm Tempered Safety Glass | EN 12150-1, ANSI Z97.1 |

| Steel Structure Finish | Hot-dip Galvanized & Powder Coated | ISO 1461 |

| Artificial Turf Pile Height | 10mm - 15mm | FIP Approved |

| Lighting Intensity | 300-500 Lux (Recreational); 500-700 Lux (Professional) | FIP Guidelines, EN 12193 |

| Wind Load Resistance | Up to 120 km/h (depending on design) | Local Building Codes |

The technical advantages of a well-engineered paddle court extend beyond mere adherence to FIP regulations, encompassing enhanced durability, superior player safety, and reduced long-term operational costs. For instance, the use of high-grade tempered glass minimises the risk of breakage and provides a seamless, transparent playing experience, particularly for panoramic padel court designs that maximise spectator visibility. The anti-corrosion treatments applied to the steel structure, such as hot-dip galvanization and advanced powder coating, ensure the court's integrity for decades, significantly reducing the need for costly repairs or replacements. This robust construction is particularly beneficial in diverse climates, from the humid tropics to freezing northern regions, protecting against rust and material degradation. Furthermore, the specialized artificial turf selected for the playing surface offers consistent ball bounce, excellent shock absorption to reduce player fatigue and risk of injury, and requires minimal irrigation or mowing, unlike natural grass. The integration of high-efficiency LED lighting systems not only provides optimal visibility during evening play but also contributes to significant energy savings, reducing utility expenses for facility operators. These comprehensive technical considerations underscore the importance of choosing a manufacturer with proven expertise in sports infrastructure, ensuring that every component, from the foundational anchors to the very top of the netting, is designed and fabricated to deliver peak performance and maximum return on investment for any commercial or private sports facility. This commitment to engineering excellence translates into a superior product that stands the test of time and intensive use.

The versatility of a padel court makes it suitable for a wide array of application scenarios, ranging from high-traffic commercial sports complexes and luxury hotels to exclusive private residential estates and corporate wellness centers. In commercial settings, the robust construction and low maintenance requirements translate directly into enhanced profitability through high utilization rates and reduced operational overheads. For hotels and resorts, adding a paddle court enhances guest amenities, attracting a broader clientele and increasing revenue streams. Private residences benefit from a premium recreational facility that adds significant value to the property while promoting an active lifestyle. The burgeoning interest from real estate developers to integrate padel facilities into new residential communities is also a testament to the sport's growing appeal and its ability to create attractive, community-focused living environments. Customization options are extensive, allowing clients to tailor designs to their specific needs and aesthetic preferences. This includes selecting frame colors that match branding, choosing specific turf colors, incorporating custom logos on the playing surface or glass, and designing unique lighting solutions. Some manufacturers also offer modular court systems that can be rapidly assembled and disassembled, providing flexibility for temporary events or future relocation. The ability to customize a padel court ensures that it seamlessly integrates into any architectural or landscape design, enhancing the overall appeal and functionality of the space.

Selecting the right manufacturer for a padel tennis court is a critical decision that impacts project success, long-term performance, and overall return on investment. Key factors to consider include the manufacturer's track record, experience in producing high-volume, high-quality sports infrastructure, and adherence to international certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. A reputable manufacturer will provide comprehensive documentation, including structural calculations, material specifications, and installation guidelines. Furthermore, assessing their capability for end-to-end service, from initial consultation and design to manufacturing, logistics, and post-installation support, is paramount. Clients should seek out manufacturers who offer robust warranty policies, reflecting their confidence in product durability and craftsmanship. For example, a 10-year warranty on structural components and a 5-year warranty on artificial turf are indicative of high-quality products. Case studies and client testimonials, along with site visits to completed projects, provide invaluable insights into a manufacturer's project execution capabilities and client satisfaction levels. Comparing different manufacturers' offerings should go beyond initial cost, focusing on the total cost of ownership, including anticipated maintenance, energy efficiency of lighting systems, and projected lifespan. A transparent quotation process that clearly delineates costs for materials, fabrication, shipping, installation, and any ancillary services is also essential. Ultimately, partnering with a manufacturer that not only understands the technical nuances of paddle racquet sports infrastructure but also offers comprehensive support and a commitment to quality ensures a successful, long-lasting investment.

A well-constructed professional padel court, utilizing high-quality materials and manufacturing processes such as hot-dip galvanization and tempered glass, can have a lifespan of 20 to 25 years or even longer for its main structural components. The artificial turf playing surface typically requires replacement every 5 to 10 years, depending on usage intensity and maintenance practices. Factors influencing longevity include climatic conditions, frequency of use, quality of initial installation, and adherence to recommended maintenance schedules. Regular cleaning of the glass walls, brushing of the turf, and occasional infill replenishment can significantly extend the life of the court and maintain optimal playing conditions. Investing in a court built to international standards with certified materials ensures maximum durability and minimizes the need for premature replacements, representing a sound long-term asset for any facility.

Maintenance for a padel court is generally low, especially compared to natural grass courts. Key requirements include regular brushing of the artificial turf to redistribute the infill (sand), prevent matting, and remove debris. This helps maintain consistent ball bounce and prolongs the turf's life. The glass walls should be cleaned periodically to ensure visibility and prevent the buildup of grime or mildew. Structural components should be inspected annually for any signs of wear, loose bolts, or corrosion, although hot-dip galvanized and powder-coated steel significantly reduces the risk of rust. Lighting systems should be checked for faulty bulbs or wiring. Proper drainage systems beneath the court are essential to prevent water accumulation. Adhering to these simple maintenance routines ensures the court remains in excellent condition, providing a safe and enjoyable playing experience for many years.

The delivery and installation timeframe for a new paddle court can vary based on the manufacturer, court customization level, shipping distance, and site preparation. Generally, manufacturing lead times range from 4 to 8 weeks, depending on the complexity of the design and order volume. Shipping can take an additional 2 to 6 weeks, particularly for international deliveries. On-site installation, assuming proper sub-base preparation is complete, typically takes 5 to 10 working days for a professional team. Therefore, clients should anticipate a total project timeline from order placement to completion ranging from 10 to 24 weeks. It is crucial to coordinate closely with the chosen manufacturer for accurate timelines, especially when dealing with specific project deadlines or concurrent construction phases. Experienced manufacturers provide detailed project schedules to ensure timely and efficient delivery and installation.

Reputable manufacturers of panoramic padel court systems typically offer comprehensive warranty packages that cover structural components for an extended period, often 10 years or more, against manufacturing defects and material failures. Warranties for artificial turf usually range from 5 to 8 years, reflecting its higher wear rate. Lighting systems and other electrical components may have separate warranties, typically 1 to 3 years. Beyond the warranty, reliable manufacturers provide excellent customer support, including technical assistance for installation queries, maintenance guidance, and prompt access to spare parts. Many also offer post-installation service contracts or scheduled inspections to ensure long-term performance. This commitment to ongoing support is vital for commercial operators who rely on uninterrupted court availability and for maintaining the value of their investment over time, providing peace of mind for clients.

This is the last article

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort

Premium Padel Court Solutions & Panoramic Designs

High-Performance Paddle Racquets for Padel & Paddle Courts

Elite Paddle Racquets: Power & Control for Padel Courts