In modern industrial sports architecture, the squash court has evolved from a niche recreational feature to an essential component of multi-functional athletic complexes. Businesses, universities, and fitness institutions increasingly invest in professionally designed squash environments to meet the demand for dynamic and high-intensity sports. From the precise surface finishes required for ball bounce accuracy to durable wall materials built to withstand repeated impacts, every detail in a squash court must adhere to international specifications. Industrial construction firms and sports developers now seek robust, scalable solutions for building courts that perform well under frequent use and environmental stress.

Equipping industrial sports centers with the right squash equipment ensures safety, performance, and longevity. Unlike home-use gear, commercial equipment must withstand continuous wear and accommodate players of all skill levels. While casual players may not notice, the quality of squash equipment in high-traffic venues can directly impact gameplay and injury prevention. Rackets must retain their tension and structure despite constant usage, while protective eyewear, gloves, and shoes must be both functional and durable. Industrial buyers often prefer bulk purchases and OEM sourcing strategies to maintain a consistent supply across multiple locations.

Although squash and racquetball differ, the racquetball racket often finds crossover application in fitness centers that support multi-sport courts. For industrial buyers, understanding the material science behind racket frames—usually composite blends of graphite, carbon, and titanium—is essential. The ideal racquetball racket must balance flexibility with strength to accommodate rapid swings and rebounding shots. When implemented in commercial settings, rackets must also pass quality control metrics for resistance to warping, handle wear, and frame cracking. As such, procurement officers for squash or racquetball clubs often evaluate rackets for both performance and durability under institutional-level use.

The industrial squash sector is significantly shaped by the performance standards set by elite-level squash club organizations. These clubs not only act as training grounds for athletes but also set expectations for the types of materials and technologies used in court construction and equipment design. The feedback from members of a squash club can inform the development of shock-absorbing wall panels, humidity-resistant flooring, and lighting systems that reduce shadow distortion. Industrial suppliers often collaborate with clubs to test new court materials or develop custom facility designs that balance performance with maintenance efficiency.

When supplying athletic institutions, one overlooked yet crucial component is the variety of squash balls types used for different skill levels and court conditions. Beginner, intermediate, and professional balls each feature distinct bounce characteristics determined by internal pressure and rubber density. For industrial distributors, managing inventories of all recognized squash balls types means not only stocking the right options but also storing them under controlled temperatures to avoid material degradation. Bulk packaging, branding, and distribution strategies are designed around supplying sports academies, gyms, and clubs that rely on consistent ball performance.

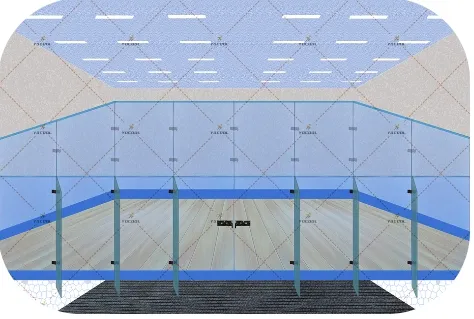

Every court must adhere to international dimensions: 9.75m in length and 6.4m in width, with walls capable of absorbing and reflecting impact uniformly. Materials such as maple hardwood floors and impact-resistant plasterboard ensure structural integrity under industrial use conditions.

High-grade squash equipment reduces risks of strain injuries, wrist impact, and vision-related mishaps. In heavily trafficked fitness centers, safety-certified gear supports insurance compliance and enhances user trust.

Their versatility and durability make them appealing in multi-use courts. Industrial facilities often offer both squash and racquetball, making dual-use rackets a practical choice for equipment standardization.

Q: What are the most common materials used in commercial squash court construction?

A: Commercial courts typically use hardwood flooring, such as beech or maple, and impact-rated wall systems made from panelled gypsum or fiberglass-reinforced plastic to ensure consistent rebound and durability.

Q: How is squash equipment selected for industrial gym chains or fitness complexes?

A: Buyers focus on high-durability gear certified by recognized sports authorities. Factors like racket head size, grip type, and string tension tolerance are assessed based on expected usage volume.

Q: What distinguishes professional squash balls from amateur ones in industrial supply?

A: Professional balls have less bounce and require higher temperature to play optimally. Industrial suppliers often recommend color-coded types to simplify selection across skill levels.

Q: Can squash clubs influence the design of future equipment and court setups?

A: Yes, data collected from club use, feedback, and wear patterns often drive innovations in court surfaces, racket ergonomics, and lighting setups used in industrial builds.

Q: What is the average lifespan of racquetball rackets in a commercial setting?

A: With proper use and storage, racquetball rackets in a commercial setting last about 6 to 12 months before requiring restringing or replacement due to frame stress.

Sports Facilities with High-Performance Indoor Racquetball and Squash Courts

Revolutionize Indoor Sports Facilities with Advanced Squash Court Installations

Master Industrial Sports Facilities with Pro Racquetball and Squash Solutions

Integration of High-Performance Squash Court Facilities

Industrial Innovation Begins with Durable Squash Court Construction

Discover Industrial-Grade Solutions for Racquet Sports Facilities