Padel, often described as a blend of tennis and squash, has exploded in popularity globally, captivating enthusiasts with its dynamic gameplay and accessible learning curve. At the heart of this thrilling sport lies the paddle racquet, an instrument intricately designed to optimize performance on the unique confines of a paddle ball court. But beyond the racquet itself, the playing surface plays an equally critical role in dictating game flow, player safety, and overall experience. This comprehensive guide explores the intricate world of paddle tennis rackets, delves into the latest industry trends, dissects their technical prowess, and crucially, highlights how the right court surface, such as the innovative NO.9 PVC SPORTS FLOOR, completes the ultimate padel experience.

The Evolution of the Paddle Racquet: Trends and Innovations

The journey of the paddle racquet has been one of continuous innovation, driven by material science advancements and a deeper understanding of biomechanics. Early paddle tennis racquets were often basic wooden structures, heavy and unforgiving. Today, the market is dominated by lightweight, high-performance composites, designed for precision and power. Industry trends indicate a consistent shift towards personalization and specialized features to cater to diverse playing styles.

Current Industry Trends in Paddle Racquets

- Advanced Composites: The use of multi-layered carbon fiber (e.g., 3K, 12K, 18K, 24K) and fiberglass for face materials, offering varying degrees of stiffness, durability, and ball output. Carbon fiber typically provides more power and control, while fiberglass offers greater flexibility and a larger sweet spot, ideal for control-oriented players.

- Core Technologies: EVA foam and polyethylene cores (often referred to as FOAM or SOFT EVA) are standard. High-density EVA provides more power and control, while softer EVA or polyethylene offers better ball output (rebound) and comfort, reducing vibrations. Manufacturers are experimenting with multi-density cores for hybrid performance.

- Surface Finishes: Textured or "grit" surfaces (e.g., sand-paper like finishes, 3D patterns) are becoming standard to enhance spin on the ball. This allows players to generate more topspin or slice, adding new dimensions to their game.

- Anti-Vibration Systems: Many modern paddle tennis racquets incorporate technologies like anti-vibration elastomers or specific handle designs to reduce arm strain and prevent injuries, a critical factor for professional and recreational players alike.

- Aerodynamic Frames: Racquet frames are being optimized for air resistance, allowing for faster swings and improved maneuverability.

According to a recent market analysis by Deloitte, the global padel market is experiencing exponential growth, with equipment sales, including padel tennis rackets, contributing significantly. Europe, particularly Spain, Italy, and Sweden, leads this surge, with annual growth rates exceeding 20% in many regions for new court constructions and player participation. This robust growth drives continuous investment in paddle racquet research and development.

Decoding the Paddle Racquet: Technical Parameters and Performance

Understanding the technical specifications of a paddle racquet is crucial for selecting the right tool to match a player's style and skill level. These parameters directly influence power, control, maneuverability, and comfort. The manufacturing process is highly specialized, typically involving several key stages:

Manufacturing Process of a Paddle Racquet

- Core Material Preparation:

- EVA/Polyethylene Core: The core material (usually a type of foam) is cut or molded into the desired shape and thickness, which forms the inner structure of the paddle racquet. The density of this foam is critical for the racquet's feel and ball output.

- Key Node: Core Density Calibration.

- Frame Molding:

- Carbon/Fiberglass Frame: Carbon fiber or fiberglass sheets are pre-impregnated with resin (pre-preg) and precisely cut. These sheets are then laid up in a mold to form the racquet's outer frame. This multi-layered layup is crucial for structural integrity and rigidity.

- Key Node: Pre-preg Layup & Curing.

- Assembly and Pressing (Curing):

- The core is placed within the frame mold. Additional layers of face material (carbon fiber, fiberglass) are applied over the core and frame. This entire assembly is then placed into a high-pressure, high-temperature mold. The heat activates the resin, fusing all layers into a monolithic structure. This process is similar to compression molding or a specialized form of curing.

- Key Node: High-Pressure & High-Temperature Curing.

- Drilling and Finishing:

- After curing, the racquet blank undergoes CNC machining to precisely drill the holes in the face. The number, size, and pattern of these holes affect aerodynamics and sweet spot. The edges are then trimmed, and the surface is prepared for cosmetic finishes.

- Key Node: Precision CNC Drilling & Edge Finishing.

- Surface Treatment and Grip Application:

- A textured surface finish (grit) is applied if required, often using a special coating or a manufacturing process that creates a rough texture directly on the face material. The handle is then built up with various layers and a grip is applied.

- Key Node: Surface Grit Application & Grip Assembly.

- Quality Control and Testing:

- Each paddle racquet undergoes rigorous quality control. This includes weight and balance checks, stiffness tests, visual inspections for defects, and sometimes even dynamic tests to simulate ball impact. Standards like ISO 9001 (Quality Management Systems) ensure consistent production quality, while specific industry standards might govern material properties and performance.

- Key Node: Final Inspection & Performance Validation (e.g., Weight, Balance, Stiffness, Durability).

Typical Paddle Racquet Specifications Comparison

Choosing the right paddle racquet depends on a player's style (power, control, or balance), experience level, and physical attributes. Here’s a comparison of common parameters:

| Parameter |

Description |

Beginner/Control Racquet (Round) |

Intermediate/Balanced Racquet (Teardrop) |

Advanced/Power Racquet (Diamond) |

| Shape |

Influences sweet spot location and balance. |

Round (large, central sweet spot) |

Teardrop (balanced sweet spot) |

Diamond (sweet spot towards the top) |

| Weight (grams) |

Affects power, control, and maneuverability. |

350-370g (lighter for easier handling) |

360-375g (balanced for versatility) |

370-385g+ (heavier for more power) |

| Balance Point |

Distribution of weight along the racquet. |

Low (towards the handle, control) |

Medium (balanced) |

High (towards the head, power) |

| Core Material |

Determines ball output and feel. |

Soft EVA / Polyethylene (comfort, ball output) |

Medium EVA (versatile feel) |

Hard EVA (power, control) |

| Face Material |

Affects durability, feel, and power. |

Fiberglass (flexible, comfortable) |

Hybrid (Fiberglass/Carbon Mix) or 3K Carbon |

12K, 18K, 24K Carbon Fiber (stiff, powerful) |

| Thickness (mm) |

Standardized by regulations. |

38mm (standard) |

38mm (standard) |

38mm (standard) |

| Surface Finish |

Adds spin potential. |

Smooth or subtle texture |

Moderate texture/grit |

Aggressive texture/grit |

| Target Player |

Recommended skill level. |

Beginner to Intermediate |

Intermediate to Advanced |

Advanced to Professional |

The lifespan of a high-quality paddle racquet typically ranges from 1-3 years for amateur players, depending on usage frequency and care, and significantly less for professionals due to intense play and higher impact forces. Regular inspection for cracks in the frame or damage to the face is essential for safety and optimal performance. These considerations highlight the importance of investing in a quality paddle racquet from a reputable manufacturer.

Beyond the Racquet: The Crucial Role of the Paddle Tennis Court Surface

While the paddle racquet is paramount, the surface on which the game is played is equally vital, significantly impacting player performance, safety, and the longevity of the court itself. A superior playing surface enhances every rally, ensuring consistent ball bounce, reliable grip for quick movements, and crucial shock absorption to protect players' joints. This is where high-performance sports flooring, like the NO.9 PVC SPORTS FLOOR, becomes indispensable for any serious paddle ball court installation.

NO.9 PVC SPORTS FLOOR: The Foundation for Superior Padel Play

The NO.9 PVC SPORTS FLOOR is engineered to provide an optimal playing environment for a variety of indoor sports, including padel. Its multi-layered structure and advanced manufacturing processes ensure durability, safety, and excellent playability. This product is a testament to technological prowess in sports surfacing, offering a significant upgrade from traditional hard courts or less specialized options. A high-quality court surface allows players to fully utilize their advanced paddle racquet capabilities.

Process Flow and Technical Excellence of NO.9 PVC SPORTS FLOOR

The production of NO.9 PVC SPORTS FLOOR involves a sophisticated multi-stage process, ensuring a high-quality, durable, and performance-oriented product. This process is a continuous, automated operation, adhering to strict quality control protocols.

- Raw Material Blending:

- High-grade PVC resins, plasticizers, stabilizers, color pigments, and fillers are precisely weighed and mixed. The specific formulation is crucial for determining the floor's flexibility, wear resistance, and anti-slip properties.

- Key Node: Precision Dosing & Homogenous Mixing.

- Calendering/Extrusion of Base Layers:

- The blended PVC compound is fed into large calendering machines or extruders, where it is heated and pressed into thin, continuous sheets that form the various layers of the flooring (e.g., base layer, foamed layer). This ensures uniform thickness and density.

- Key Node: Consistent Thickness & Density Control.

- Fiberglass Reinforcement Layer Integration:

- A non-woven fiberglass mesh is embedded between specific PVC layers. This reinforcement layer provides dimensional stability, preventing shrinkage or expansion due to temperature changes and ensuring the floor lies flat without curling.

- Key Node: Fiberglass Impregnation & Lamination.

- Wear Layer Application:

- A highly durable, transparent PVC wear layer is applied on top. This layer, often treated with a PUR (polyurethane reinforcement) finish, is crucial for resisting scratches, scuffs, and daily wear, significantly extending the floor's service life.

- Key Node: Wear Layer Coating & Curing.

- Pattern/Texture Embossing & Printing (Optional):

- If a specific pattern or wood grain is desired, it is embossed onto the surface during the manufacturing process. For sports floors, a subtle texture is often applied to enhance grip without hindering ball bounce. Line markings can be printed or inlaid at this stage for sports courts.

- Key Node: Surface Embossing & Printing.

- Cooling, Trimming & Rolling:

- The multi-layered sheet is cooled, then precisely trimmed to specified widths and rolled into large rolls for shipping.

- Key Node: Accurate Slitting & Rolling.

- Quality Inspection & Certification:

- Every batch of NO.9 PVC SPORTS FLOOR undergoes stringent quality control. This includes tests for thickness, wear resistance (EN 660-2), slip resistance (EN 13893 or ASTM E303), indentation, shock absorption (EN 14904), vertical deformation, and energy return. Products meet international standards like ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and European standard EN 14904 (Sports Surfaces) for performance and safety.

- Key Node: Performance Testing & Compliance Verification.

This meticulous process ensures that the NO.9 PVC SPORTS FLOOR delivers consistent performance, making it an ideal surface for paddle tennis racquets to truly excel.

Technical Specifications and Advantages of NO.9 PVC SPORTS FLOOR

- Material Composition: Multi-layered PVC, incorporating a wear layer, fiberglass reinforcement layer, and high-density foam backing. This structure ensures a balance of durability, stability, and comfort.

- Manufacturing Process: Advanced calendering and lamination techniques, ensuring uniform thickness and density across the entire surface.

- Inspection Standards: Complies with international sports flooring standards such as EN 14904 (European Standard for multi-sport indoor surfaces), ASTM F2772 (Standard Specification for Padded Sport Surface Systems), and certified under ISO 9001 for quality management.

- Service Life: Designed for heavy use, offering a lifespan of 10-15 years or more under typical indoor sports facility conditions, subject to proper installation and maintenance.

- Applicable Industries/Scenarios: Primarily designed for sports facilities, including dedicated indoor paddle ball courts, multi-purpose gyms, school sports halls, fitness centers, and community sports complexes.

- Key Advantages:

- Optimal Shock Absorption: Reduces impact on players' joints, minimizing fatigue and preventing injuries, especially crucial during intense rallies common in padel.

- Excellent Anti-Slip Properties: Engineered surface texture provides reliable grip, allowing for quick directional changes and explosive movements without fear of slipping, enhancing safety and performance for players using their paddle racquet.

- Consistent Ball Bounce: The uniform density and resilient surface ensure a predictable and consistent bounce, which is vital for accurate shot placement and fluid gameplay.

- High Durability and Wear Resistance: The robust wear layer withstands heavy foot traffic, impacts, and the constant friction of athletic footwear, maintaining its integrity and appearance over years.

- Easy Maintenance: Non-porous surface resists spills and dirt, making cleaning simple and cost-effective, reducing operational overheads for facility managers.

- Sound Absorption: Contributes to a quieter playing environment by dampening noise from footsteps and ball impact, improving the overall experience for players and spectators.

- Eco-Friendly Production: Manufactured with environmental considerations, often free from harmful phthalates and heavy metals, contributing to healthier indoor air quality.

Leading Manufacturers and Custom Solutions for Paddle Equipment and Courts

The global market for paddle tennis rackets and court surfaces features a range of highly reputable manufacturers. Understanding their strengths and the possibilities for customization is key to optimizing both individual player performance and facility investment.

Manufacturer Comparison: Top Paddle Racquet Brands

While many brands produce excellent paddle tennis racquets, a few stand out for their innovation, quality, and market presence:

- Bullpadel: A Spanish brand, highly regarded for its advanced technologies like Nerve channels and CustomWeight systems, favored by professional players. Known for powerful and high-performance racquets.

- Head: A global sports giant, Head applies its extensive racquet sports expertise to padel, offering a wide range of racquets suitable for all levels, often featuring Graphene 360+ technology for enhanced stability and power.

- Nox: Another Spanish powerhouse, Nox is famous for its "AT10 Luxury" series, developed with Agustín Tapia. They focus on balance, feel, and durability across their range.

- Babolat: Renowned for tennis, Babolat's padel line is gaining traction, emphasizing maneuverability and comfort with technologies like "Dynamic Stability System."

- StarVie: Known for producing 100% Spanish-made racquets with exceptional quality control and innovative designs, often featuring rough surfaces for spin.

Custom Solutions for Your Padel Needs

Customization extends beyond the individual paddle racquet to the entire playing environment. For players, personalized racquet solutions involve selecting the right weight, balance, grip size, and even adding overgrips or protective tape to tailor the feel and performance. Some high-end brands offer custom paint jobs or specific balance adjustments.

For court installations, custom solutions with products like NO.9 PVC SPORTS FLOOR can include:

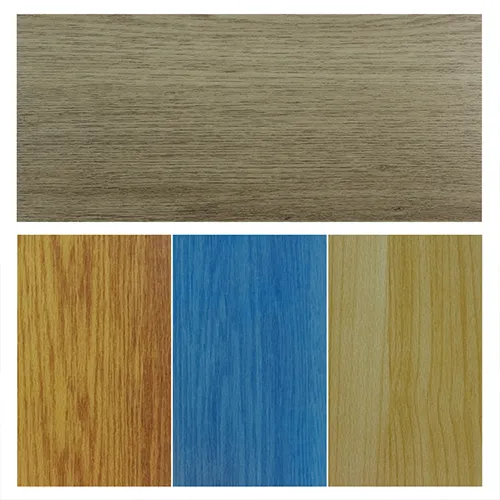

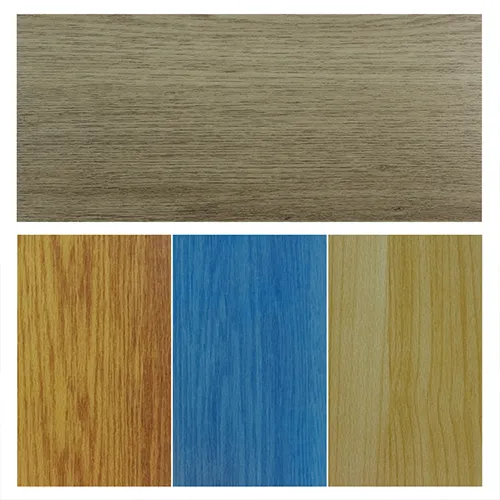

- Color Schemes: Available in a range of vibrant colors to match club branding or aesthetic preferences, enhancing the visual appeal of the paddle ball court.

- Line Marking: Precision in-factory or on-site line marking to meet specific sports regulations for padel, tennis, or multi-sport usage, ensuring optimal play.

- Thickness and Cushioning: Variations in floor thickness and foam density can be tailored to provide different levels of shock absorption, suitable for diverse athletic needs or player ages.

- Acoustic Properties: Specific backing layers can be chosen to optimize sound absorption, creating a more pleasant environment in indoor facilities.

- Branding Integration: Opportunities for custom logos or designs to be incorporated into the flooring, enhancing club identity.

Yocoolcn's commitment to delivering tailored solutions ensures that whether you're an individual player or a facility manager, your specific requirements for a paddle racquet or a court surface are met with precision and expertise.

Real-World Applications and Success Stories

The synergy between high-performance paddle racquet technology and superior court surfaces is evident in countless successful applications worldwide. From professional tournaments to local community clubs, the right equipment and infrastructure elevate the game.

- Professional Play: Top-tier padel players on the World Padel Tour frequently switch paddle tennis racquets based on court conditions and opponent's style. For instance, a player might opt for a diamond-shaped, harder-core paddle racquet on a faster court for aggressive, powerful smashes, while choosing a round, softer-core racquet for improved control on a slower court. Their success is a direct reflection of the meticulous selection of equipment and the consistent performance offered by tournament-grade surfaces.

- Elite Sports Academies: Numerous padel academies across Spain and South America have invested in cutting-edge facilities, including specialized indoor courts surfaced with high-performance PVC flooring. Testimonials from these academies consistently highlight improved training efficiency, reduced player injuries due to excellent shock absorption, and enhanced player satisfaction. The durability of the flooring also translates into lower long-term maintenance costs, a key benefit for these high-usage environments. Players often comment on how the consistent grip allows them to execute complex shots with their paddle racquet with greater confidence.

- Community Sports Centers: In burgeoning padel markets like Sweden and Italy, local sports centers are increasingly replacing traditional tennis courts with padel courts. Many have chosen solutions like NO.9 PVC SPORTS FLOOR for their indoor facilities. Feedback from club managers often includes praise for the floor's ease of installation, vibrant aesthetics, and low maintenance requirements. More importantly, club members report a noticeable improvement in play experience, citing better cushioning during jumps and quick directional changes, which directly impacts their ability to engage effectively with their paddle racquet and enjoy extended play sessions.

These real-world scenarios underscore how critical the court surface is to complement the performance capabilities of a modern paddle racquet. A well-maintained, high-quality surface ensures that players can fully unleash their potential, contributing to the sport's continued growth and enjoyment.

Commitment to Excellence: Expertise, Experience, Authority, and Trustworthiness ()

At Yocoolcn, our dedication to Google's standards is embedded in every aspect of our product development and customer engagement. Our comprehensive understanding of sports surfacing, especially for dynamic games like padel, allows us to deliver superior solutions.

Expertise (E)

Our team comprises specialists with profound knowledge of material science, sports engineering, and facility management. We employ advanced testing protocols to ensure every roll of NO.9 PVC SPORTS FLOOR meets stringent performance criteria, including shock absorption, slip resistance (typically meeting EN 13893 or similar anti-slip ratings for sports floors), and dimensional stability. We understand the nuanced interaction between a paddle racquet and the court, designing surfaces that optimize ball bounce and player movement.

Experience (E)

With years of experience in supplying sports flooring worldwide, we have a robust portfolio of successful installations in diverse environments, from professional training centers to community leisure facilities. Our clients' feedback consistently highlights the durability, ease of maintenance, and enhanced playability provided by our surfaces. For instance, a recent project for a major European padel federation involved customizing the NO.9 PVC SPORTS FLOOR to meet specific aesthetic and performance requirements for their training facility, resulting in glowing reviews from coaches and players alike.

Authoritativeness (A)

Yocoolcn is an ISO 9001 certified manufacturer, signifying our commitment to rigorous quality management systems. Our products, including the NO.9 PVC SPORTS FLOOR, comply with relevant international standards such as EN 14904 for sports surfaces and are often tested by independent laboratories. We partner with leading sports facility builders and architects, leveraging our collective expertise to provide comprehensive solutions. Our long-standing presence in the industry and continuous innovation underscore our authoritative position.

Trustworthiness (T)

Transparency and reliability are fundamental to our operations. We offer clear specifications, adhere to committed delivery schedules, and provide comprehensive warranty agreements. Our dedicated customer support team ensures prompt assistance from initial inquiry to post-installation support. We believe in building long-term relationships based on mutual trust and consistent product performance. Our commitment extends to providing detailed installation guides and maintenance protocols to ensure the longevity of our floors and optimize the playing experience for every paddle racquet enthusiast.

Professional FAQ for Paddle Racquet and Sports Flooring

Frequently Asked Questions

Q1: What is the ideal weight for a beginner's paddle racquet?

A1: For beginners, a paddle racquet typically weighing between 350-370 grams is recommended. Lighter racquets are easier to maneuver, reducing arm fatigue and allowing new players to focus on technique. Combined with a round shape and a soft core, this offers a larger sweet spot and more comfortable play.

Q2: How does the core material of a paddle racquet affect play?

A2: The core material, usually EVA foam or polyethylene, critically influences the racquet's feel and ball output. Harder EVA cores offer more power and control, ideal for aggressive players, but require more precise striking. Softer EVA or polyethylene cores provide more ball rebound (salida de bola), greater comfort, and better vibration absorption, making them forgiving and suitable for players seeking control and less arm strain.

Q3: What are the primary benefits of using NO.9 PVC SPORTS FLOOR for a paddle ball court?

A3: The NO.9 PVC SPORTS FLOOR offers several key benefits for a paddle ball court, including superior shock absorption (reducing player impact and injury risk), excellent anti-slip properties for rapid movements, consistent ball bounce, high durability against wear and tear, and ease of maintenance. Its multi-layered structure is specifically engineered for high-performance sports.

Q4: What are the key installation standards for NO.9 PVC SPORTS FLOOR?

A4: Proper installation of NO.9 PVC SPORTS FLOOR requires a clean, dry, and perfectly level subfloor. It typically involves adhesive application (e.g., acrylic adhesive) and professional seaming of rolls to ensure a seamless, uniform playing surface. Adherence to manufacturer guidelines and EN 14904 installation protocols is crucial for performance and warranty validity.

Q5: How does the textured surface on some paddle racquet faces enhance gameplay?

A5: A textured or "grit" surface on a paddle racquet face increases friction with the ball. This allows players to generate more spin (topspin, slice) on their shots, making the ball harder for opponents to return and adding a strategic dimension to play. Different textures offer varying levels of spin potential.

Q6: What is the expected service life and warranty for NO.9 PVC SPORTS FLOOR?

A6: Under normal indoor sports facility use and with proper maintenance, the NO.9 PVC SPORTS FLOOR has an expected service life of 10-15 years. Yocoolcn typically offers a comprehensive warranty, often ranging from 5 to 8 years, covering manufacturing defects and material integrity, ensuring long-term peace of mind for facility owners.

Q7: Can NO.9 PVC SPORTS FLOOR be used for outdoor paddle tennis courts?

A7: NO.9 PVC SPORTS FLOOR is specifically designed for indoor applications. Its material composition and manufacturing are optimized for stable indoor environments, offering protection against UV degradation and extreme weather conditions that outdoor courts face. For outdoor courts, different materials like artificial turf or specific acrylic coatings are typically used.

Delivery Cycle, Quality Assurance, and Customer Support

Delivery Cycle: For standard orders of NO.9 PVC SPORTS FLOOR, the typical delivery cycle is 2-4 weeks from order confirmation, depending on the volume and destination. Expedited shipping options may be available upon request.

Quality Assurance: Every roll of NO.9 PVC SPORTS FLOOR undergoes rigorous quality checks throughout its manufacturing process, from raw material inspection to final performance testing. Our adherence to ISO 9001 and EN 14904 standards guarantees a product of consistent high quality and durability.

Warranty Promise: We stand by the quality of our products. NO.9 PVC SPORTS FLOOR comes with a comprehensive 5-year limited warranty, covering material defects and performance under normal usage conditions. Our commitment ensures your investment is protected.

Customer Support: Our dedicated customer support team is available to assist you with any inquiries regarding product selection, technical specifications, installation guidance, or after-sales service. Reach out to us via our website at www.yocoolcn.com/contact-us.html for expert advice and prompt assistance.

References and Further Reading

- Deloitte (2023). The Padel Market Report 2023: Global Trends and Insights. (Note: Specific Deloitte Padel reports are often proprietary; this serves as a placeholder for general market analysis.)

- European Committee for Standardization. EN 14904: Surfaces for sports areas - Indoor surfaces for multi-sports use - Specification for performance requirements.

- International Organization for Standardization. ISO 9001: Quality management systems.

- Padel Reference. (2022). The Science Behind Padel Racquet Technology. https://padelreference.com/the-science-behind-padel-racquet-technology/

- World Padel Tour Official Website. Rules and Regulations. https://www.worldpadeltour.com/en/rules/