(rubber brick)

Rubber bricks have emerged as a game-changer in commercial and industrial flooring, combining 97% recycled content with unmatched durability. Unlike traditional concrete or vinyl surfaces, these interlocking units withstand impacts up to 18,000 PSI while maintaining 0.28mm/year wear rates. The global rubber flooring market, valued at $10.2B in 2023, projects 6.8% CAGR growth through 2030, driven by demand in healthcare and education sectors.

Advanced vulcanization processes enable rubber brick

s to achieve:

The closed-cell structure prevents liquid penetration, reducing microbial growth by 83% compared to porous alternatives.

| Manufacturer | Thickness (mm) | Load Capacity | Color Options | Warranty |

|---|---|---|---|---|

| FlexiTread Pro | 15-40 | 850 lb/sq.ft | 12 | 25 years |

| PaveSafe Industrial | 20-50 | 1,200 lb/sq.ft | 8 | 15 years |

| EcoRubber Solutions | 10-30 | 650 lb/sq.ft | 18 | 30 years |

Modular systems support:

Boston General Hospital reported:

Automotive plants utilizing conductive rubber bricks achieved 92% static dissipation in assembly lines.

Life cycle assessments reveal:

With 14 patents filed in Q1 2024 for improved thermal stability (-40°F to 212°F operating range) and RFID-enabled wear monitoring, rubber flooring systems now integrate with smart building management platforms. Early adopters report 40% reduction in facility downtime through predictive maintenance capabilities.

(rubber brick)

A: Rubber brick flooring offers durability, slip resistance, and noise reduction. It’s ideal for high-traffic areas like gyms or workshops. Its modular design also allows for easy installation and replacement.

A: Clean rubber floors regularly with a pH-neutral cleaner and avoid abrasive tools. Routine sweeping and occasional deep cleaning will preserve its appearance. Proper maintenance extends lifespan and ensures safety.

A: Yes, rubber bricks are UV-resistant and weatherproof, making them suitable for outdoor use. They provide excellent traction in wet conditions. Ensure proper drainage during installation to prevent water pooling.

A: Rubber bricks are modular tiles, ideal for DIY projects and spot repairs. Rubber rolls provide seamless coverage for large areas. Both offer similar durability but differ in installation flexibility.

A: Many rubber floors are made from recycled materials like tires. They are 100% recyclable and reduce landfill waste. Look for certifications like GREENGUARD for eco-conscious options.

This is the last article

Rubber Bricks & Flooring Durable, Eco-Friendly Shock-Absorbent Solutions

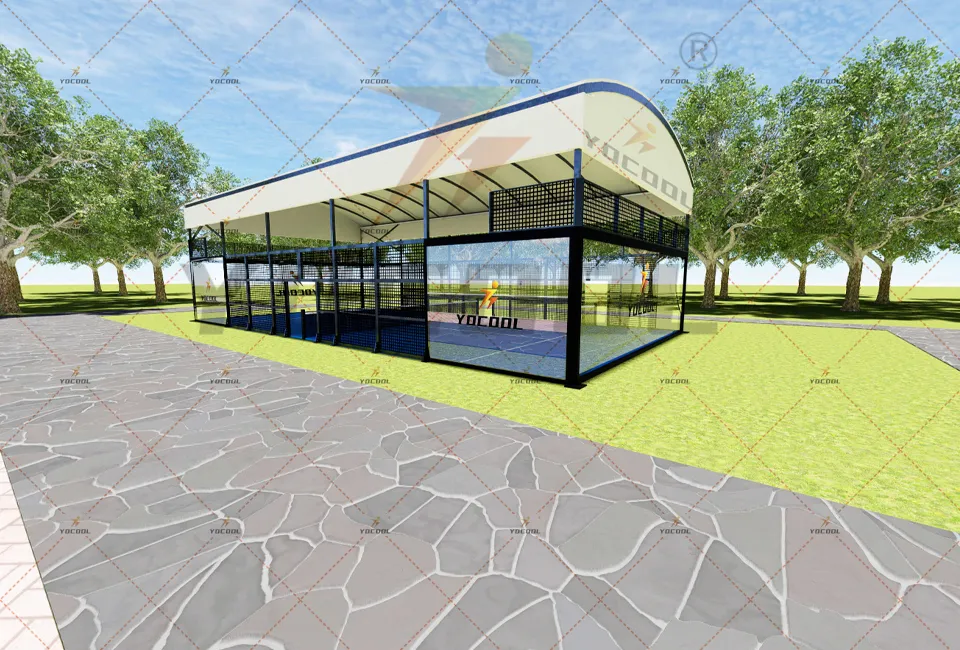

Industrial Flooring Solutions & China Paddle Tennis Court Cost Guide

Homogeneous Transparent Rubber Flooring Durable & Slip-Resistant

Homogeneous Transparent Rubber Flooring Durable & Slip-Resistant

Industrial Flooring for Paddle, Squash, Tennis Courts & Factories Durable Solutions

Durable & Slip-Resistant Rubber Floor Mats Heavy-Duty Protection