The Rise of Squash Court Factories Revolutionizing Sports Infrastructure

In recent years, the demand for squash as a popular sport has surged globally, leading to the establishment of specialized squash court factories. These factories play a crucial role in revolutionizing sports infrastructure by providing high-quality, standardized courts that promote the game while catering to the diverse needs of players, clubs, and educational institutions.

The Evolution of Squash

Squash has been played for over a century, originally gaining traction in England before spreading to other parts of the world. As the sport evolved, so did the facilities required to accommodate its growth. Historically, many squash clubs constructed courts on an ad-hoc basis, resulting in varying quality and dimensions. However, this inconsistency posed challenges for both players and coaches. To combat these issues, the emergence of dedicated squash court factories paved the way for standardized, high-performance courts that adhere to international regulations.

The Manufacturing Process

Squash court factories utilize state-of-the-art technology and experienced craftsmanship to build courts that meet the specific requirements of the sport. The manufacturing process involves several steps, including material selection, court design, and quality control.

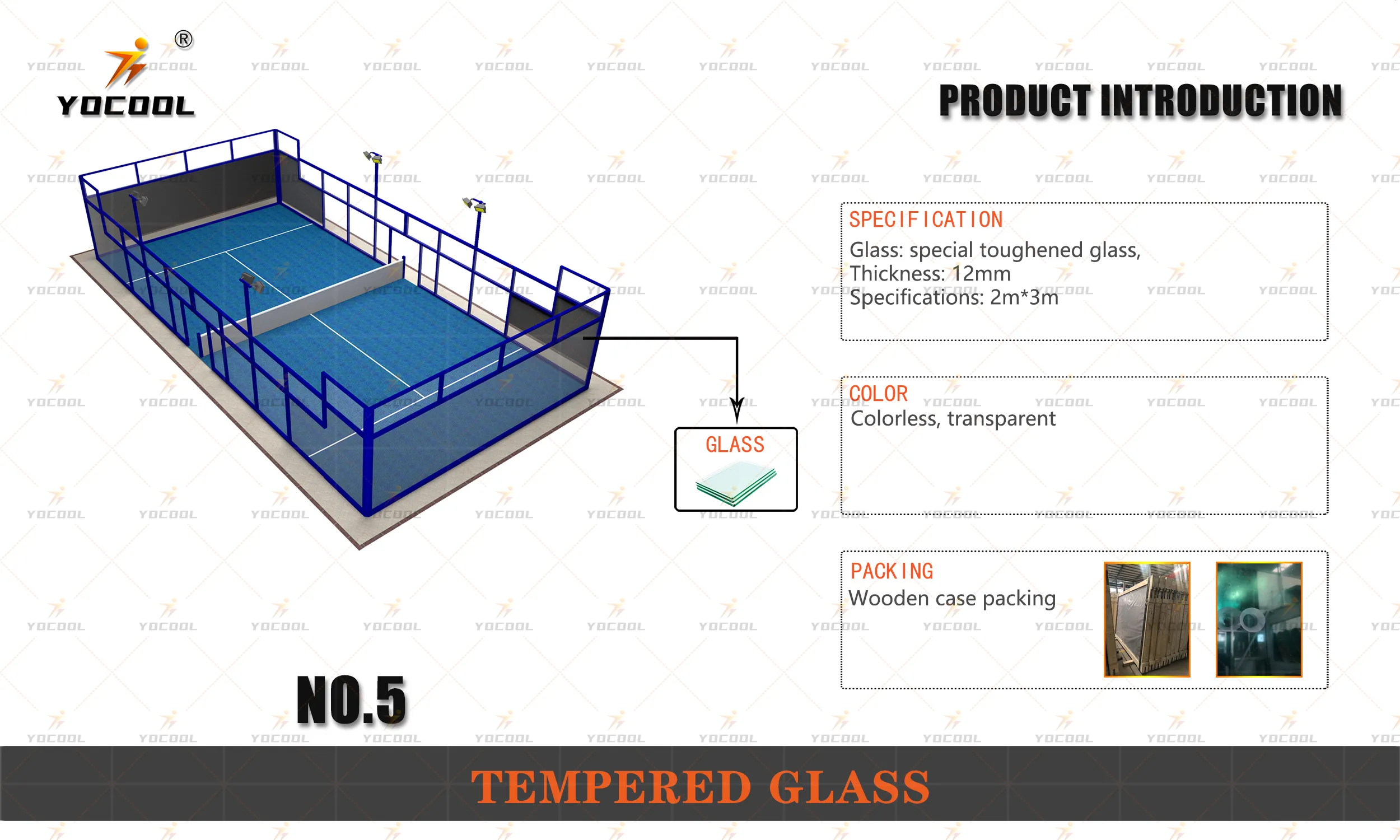

1. Material Selection The choice of materials is critical to ensuring the durability and performance of a squash court. Factories typically use high-quality wood, glass, and specialized flooring materials that enhance player safety and provide optimum ball rebound.

2. Design Standards Adhering to the official dimensions set by the World Squash Federation (WSF) is paramount. A standard squash court measures 9.75 meters in width, 6.4 meters in height, and has a length of 9.75 meters. Factories incorporate these measurements into their designs, ensuring that courts are not only compliant but also suitable for competitive play.

3. Quality Control After manufacturing, each court undergoes rigorous quality testing and inspection to guarantee that it meets the highest standards. This includes evaluating the court's surface consistency, wall integrity, and overall aesthetic appeal.

Benefits of Squash Court Factories

The establishment of squash court factories offers multiple advantages

- Standardization With factories producing courts to a consistent standard, players benefit from a uniform playing experience regardless of where they compete. This consistency is vital for skill development and allows for fair competition.

- Customization Options Beyond standard designs, many factories offer customization options, enabling clubs and organizations to create courts that reflect their branding or specific requirements. This flexibility helps cater to the unique needs of clients, whether for professional tournaments, recreational use, or school facilities.

- Cost Efficiency By producing courts in bulk, factories can reduce costs associated with construction and installation. This efficiency allows more facilities to invest in high-quality courts, thus promoting the sport at grassroots levels.

- Future-Proofing With technology constantly evolving, squash court factories are better poised to incorporate new materials and designs that enhance player experience. For instance, some factories are exploring the use of sustainable materials, aligning with broader environmental goals.

The Future of Squash Court Factories

As the popularity of squash continues to grow, the future of squash court factories looks bright. Innovations and advancements in manufacturing technology are likely to further enhance court quality, while increased awareness of the benefits of squash will encourage clubs and institutions to invest in dedicated facilities.

Government initiatives, private sponsorships, and community engagement will also play a pivotal role in the expansion of squash infrastructure. As more people are introduced to the sport, squash court factories will be instrumental in ensuring that quality courts are accessible to all.

Conclusion

In summary, squash court factories are transforming the landscape of squash infrastructure, providing essential support for the growth of the sport. Through standardization, customization, and cost efficiency, these factories are making high-quality courts available to players at all levels. As the sport continues to thrive, squash court factories will be at the forefront of promoting and facilitating the love for squash around the world.

Premium Rubber Composite Floor for Ultimate Durability & Safety Rubber Floor Mat Solutions

High-Quality Industrial Flooring Solutions for Factories Expert Installation & Cost Saving

Premium Rubber Brick Flooring Durable & Slip-Resistant

Durable & Non-Slip Rubber Flooring for Gym, Garage, Home

Durable Industrial Flooring Solutions China Padel Install

Durable Rubber Floor Slip-Resistant & Easy Clean