(industrial flooring)

Modern manufacturing plants and sports facilities require specialized flooring systems that withstand extreme conditions while maintaining safety standards. Industrial-grade surfaces endure chemical exposure, heavy machinery loads exceeding 5 tons per square meter, and constant abrasion while providing critical non-slip properties. In China's rapidly expanding industrial sector, flooring installation projects have grown 17% annually since 2020 according to the International Facility Management Association, with epoxy resins dominating 62% of new installations.

Premium industrial flooring

solutions incorporate nanotechnology-enhanced polymers that outperform traditional concrete. Key technological advantages include:

Third-party testing confirms advanced urethane systems maintain structural integrity after 1.2 million forklift passes - triple the lifespan of conventional alternatives.

| Manufacturer | Compressive Strength | Chemical Resistance Rating | Cure Time | Global Projects |

|---|---|---|---|---|

| Flowcrete | 85 MPa | AA (ASTM D1308) | 24 hours | 5,200+ |

| Sika | 78 MPa | A+ (ASTM D1308) | 36 hours | 3,700+ |

| BASF | 92 MPa | AAA (ASTM D1308) | 18 hours | 6,500+ |

Independent laboratory assessments demonstrate BASF's polyurethane systems deliver 99.2% UV stability after 10,000 hours of accelerated weathering tests.

Customization parameters address site-specific challenges through computational modeling:

The Shenzhen battery plant project required 18 specialized formulations across different facility sections, reducing maintenance costs by 40% during the first operational year.

Shanghai automotive facility (2023): Installed 38,000m² of conductive polyaspartic flooring capable of dissipating 10KV electrostatic charges. The solution withstood daily exposure to battery acids and hydraulic fluids while meeting ISO 14644-1 cleanroom standards.

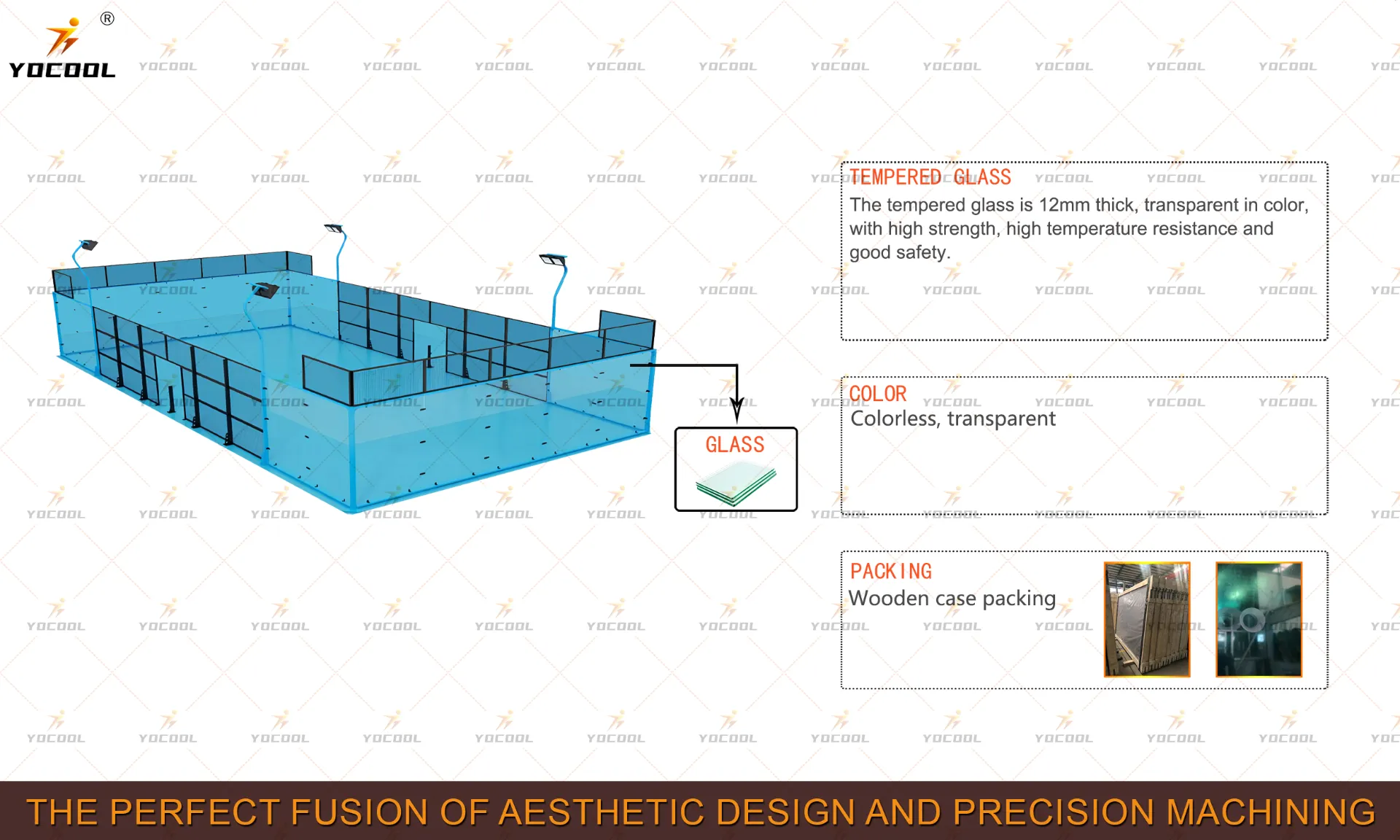

Zhejiang padel court complex: Professional-grade modular tiles with 12mm shock absorption installed over concrete substrate. Surface testing showed consistent ball bounce accuracy within 1.5% deviation and 200% improved abrasion resistance compared to standard sports surfaces.

Quality execution requires precise moisture vapor emission rate (MVER) testing prior to installation. Best practices include:

Projects implementing ISO 9001-certified installation protocols report 92% fewer surface defects during the warranty period.

Emerging developments focus on sustainability without compromising durability:

Bio-based epoxy resins derived from industrial plant oils now achieve comparable performance to petroleum-based systems with 65% lower carbon footprint. Closed-loop recycling systems can reprocess end-of-life polymer flooring into new raw material, with pilot programs achieving 89% material recovery rates.

Researchers at Tongji University are developing photocatalytic titanium dioxide coatings that break down volatile organic compounds under normal facility lighting - a technology projected to dominate 45% of the Chinese industrial flooring market by 2028.

(industrial flooring)

A: Common materials include epoxy resin, polyurethane, and methyl methacrylate. These durable coatings resist chemicals, impact, and heavy traffic. They provide seamless, low-maintenance surfaces for factories and warehouses.

A: Epoxy offers exceptional durability against machinery and chemical spills. Its customizable slip-resistance enhances safety, while easy cleaning reduces maintenance costs. This makes it ideal for manufacturing plants or logistics centers.

A: Absolutely. Modified acrylic or polyurethane systems provide shock absorption and consistent ball bounce for padel courts. China installers combine these with anti-slip textures for optimal playability and long-term outdoor resilience.

A: Most projects complete in 3-7 days depending on substrate preparation needs. Modern polymer systems cure rapidly – acrylic padel surfaces often finish within 48 hours. Weather-resistant formulations ensure reliability in China's varied climates.

A: Routine sweeping and occasional damp mopping suffice for epoxy floors. For China padel courts, quarterly inspections for surface wear and UV coating renewal are recommended. All materials resist staining to minimize upkeep.

Premium Padel Court Solutions for Clubs & Resorts | Durable & Panoramic Design

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design