Understanding Professional Ping Pong Paddle Factories

Ping pong, or table tennis, has evolved from a leisurely pastime to a highly competitive sport played worldwide. Central to this evolution is the equipment used, notably the paddle. Professional ping pong paddles play a crucial role in determining a player's performance, leading to a growing demand for high-quality paddles. Consequently, professional ping pong paddle factories have sprung up globally to meet this need, each contributing to the craftsmanship, design, and technology of paddles.

The Manufacturing Process

At the heart of professional ping pong paddle factories lies a meticulous manufacturing process that combines traditional craftsmanship with modern technology. The manufacturing of a ping pong paddle involves several key components the blade, the handle, and the rubber. Each aspect requires careful consideration.

1. Blade Construction The blade is typically made from layers of wood, though some players might prefer composite materials for added versatility and control. Factories often utilize different types of wood for varying effects on gameplay. For instance, balsa wood is lightweight and provides speed, while denser woods offer more control. Factories carefully select and laminate these materials to achieve a specific balance between speed and control.

2. Handle Design The handle of a paddle is designed for comfort and precision. Various shapes and sizes cater to different grip styles, such as shakehand andpenhold. Factories often ergonomically design handles and may use specialized finishes to prevent slippage during play.

3. Rubber Application The rubber is critical for ball interaction, offering spin and speed. Factories typically use high-quality, ITTF-approved rubber that meets competitive standards. The choice of rubber thickness and texture significantly influences gameplay, and manufacturers often conduct extensive testing to ensure optimal performance.

Technology and Innovation in Paddle Design

Professional ping pong paddle factories are not just about traditional craftsmanship; they are at the forefront of technological innovation as well. Advances in materials science have significantly improved paddle performance. The use of synthetic materials and improved bonding techniques allows for lighter, stronger paddles that offer enhanced power without compromising control.

Moreover, many factories have adopted computer-aided design (CAD) tools to create more precise and customizable paddles. Players can now choose specifications tailored to their style, including paddle weight, balance, and surface friction. This level of customization allows athletes to feel more connected to their equipment, leading to improved performance on the court.

Globalization of Ping Pong Paddle Production

While there are notable paddle factories in countries like Japan and Germany that have built a reputation for high-quality craftsmanship, the globalization of manufacturing has led to a diverse marketplace for paddles. Factories in countries like China and Taiwan have emerged as significant players, offering affordable yet high-performance paddles. This competition has pushed established brands to innovate continuously, ensuring that players at all levels have access to quality equipment.

Environmental Considerations

As sustainability becomes a priority in manufacturing, professional ping pong paddle factories are also adapting. Many factories are now sourcing materials from sustainable forests and employing eco-friendly production methods. Biodegradable rubbers and environmentally safe finishes are becoming standard, aligning with the eco-conscious preferences of many modern athletes.

Conclusion

Professional ping pong paddle factories play an invaluable role in the sport, creating equipment that can enhance a player's skills and performance. As the demand for high-quality paddles grows, these factories must continue to innovate while retaining the essence of traditional craftsmanship. The balance of technology and tradition will shape the future of ping pong paddles, making them more accessible and performance-oriented for players around the globe. In an era where competition in sports equipment is fierce, manufacturers that embrace both modern technology and sustainability will undoubtedly set themselves apart in the dynamic world of professional table tennis.

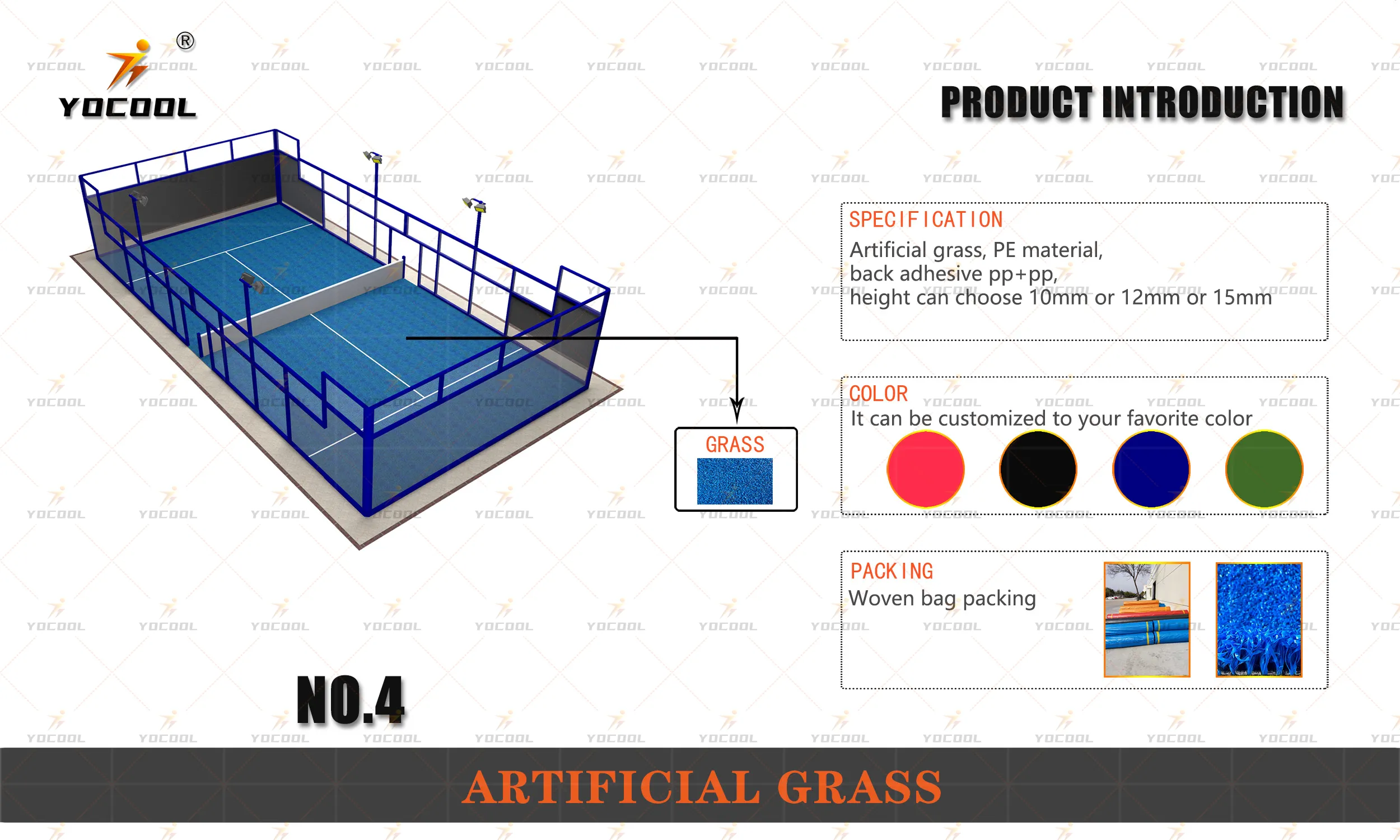

Premium Padel Courts: Expert Design & Installation Services

Premium Padel Courts: Panoramic Designs & Custom Builds

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort

Premium Padel Court Solutions & Panoramic Designs