Padel, a dynamic and accessible racquet sport, has experienced an exponential surge in global popularity. This growth is not merely a fleeting trend but a fundamental shift in sports infrastructure, driving significant demand for high-quality, durable, and technologically advanced padel court facilities. For B2B stakeholders, including sports facility developers, real estate investors, hotel chains, and private club owners, understanding the nuances of padel court construction, material science, and strategic implementation is paramount to maximizing return on investment and ensuring long-term operational success. This comprehensive guide delves into the critical aspects of padel court development, from industry trends and technical specifications to manufacturing processes and tailored solutions, offering insights crucial for informed decision-making.

The increasing adoption of padel tennis court facilities across Europe, the Middle East, North America, and parts of Asia underscores a broader shift towards recreational sports that blend social interaction with competitive play. This momentum is supported by robust industry investments and innovations in court design, material engineering, and integrated technologies, promising a lucrative future for those who align with this burgeoning market.

The global paddle court market is characterized by several key trends. Firstly, there's a strong emphasis on sustainability, with increasing demand for courts built using recycled materials and energy-efficient lighting systems. Secondly, technological integration, such as smart booking systems, live-streaming capabilities, and performance tracking, is becoming a standard expectation, particularly in premium facilities. Thirdly, the expansion into diverse geographical regions, often driven by the success of professional padel tours, is creating new opportunities for facility development.

Market data reflects this growth trajectory. According to a recent report by Allied Market Research, the global padel equipment and court market was valued at approximately $250 million in 2021 and is projected to reach over $500 million by 2030, exhibiting a Compound Annual Growth Rate (CAGR) of over 8%. This significant growth highlights the viability and potential profitability for businesses investing in high-quality paddle tennis court installations. The shift towards all-weather solutions, such as courts with separated roofs, further extends the playing season and revenue potential, mitigating concerns related to adverse weather conditions.

A thorough understanding of the technical specifications is critical for any serious investment in a padel court. Standard dimensions for a double padel court are 20 meters long by 10 meters wide. The court is enclosed by walls, typically a combination of glass and mesh fencing. The quality and type of materials used directly impact the court's performance, durability, and safety.

| Parameter | Specification (Standard FIP Regulations) | Impact on Performance/Durability |

|---|---|---|

| Court Dimensions | 20 meters (length) x 10 meters (width) | Ensures fair play and adherence to international competition standards. |

| Structural Frame | Galvanized steel tubing (typically 80x80mm, 100x50mm, or similar), minimum 2mm wall thickness. | Provides structural integrity, wind resistance, and long-term stability. Galvanization prevents rust. |

| Glass Walls | Tempered glass, 10mm or 12mm thick. Rear walls: 4m high. Side walls: 3m high for first 2m, then 4m for next 2m, followed by 3m height. | Safety (shatters into small, less harmful pieces), consistent ball rebound, aesthetic appeal (especially for panoramic padel court designs). |

| Mesh Fencing | Electro-welded mesh, 50x50mm or 25x50mm, 4mm or 5mm wire thickness. Hot-dip galvanized and powder coated. | Durability, safety barrier, ball containment. Small mesh prevents ball trapping. |

| Artificial Turf | Monofilament or fibrillated polyethylene (PE) or polypropylene (PP) fibers, 10mm to 15mm pile height. FIP-approved. | Optimal ball bounce, player comfort, reduced injury risk, all-weather playability. |

| Infill Material | Silica sand (washed, round grains), 8-12 kg/sqm. | Stabilizes turf fibers, provides consistent ball slide and grip for players. |

| Lighting | 8 LED floodlights (4 per side), minimum 200-300 Lux for recreational play; 500-700 Lux for professional. | Extends playing hours, ensures visibility, energy efficiency, flicker-free illumination. |

| Foundation | Reinforced concrete slab or perimeter beam with aggregate base. | Ensures court stability, proper drainage, and prevents structural settling. |

The choice of materials, from the grade of steel to the density of the artificial turf and the thickness of the glass, directly correlates with the court's overall performance and longevity. Investing in higher-grade materials and adhering to international standards such as those set by the FIP (International Padel Federation) is crucial for creating a premium playing experience and minimizing maintenance costs over the court's service life, which can exceed 15-20 years with proper care.

The fabrication of a high-quality padel court involves a sophisticated multi-stage manufacturing process, ensuring precision, durability, and safety. This section outlines the typical workflow and the critical quality control checkpoints that distinguish a superior product.

The process begins with the selection of high-grade raw materials. For the structural frame, this involves sourcing structural steel (e.g., S235JR or S355JR grade) that meets specific strength and chemical composition requirements. Glass for the walls must be of opti-white or low-iron tempered glass, typically 10mm or 12mm thick, meeting EN 12150 standards for safety and resistance. Artificial turf rolls are sourced from reputable manufacturers, often accompanied by certifications for UV resistance, wear, and tear. Each batch of raw material undergoes stringent quality checks to ensure compliance with international standards such as ISO 9001 for quality management systems and relevant ASTM or EN standards for material properties.

This stage involves the precision cutting, drilling, and welding of steel profiles. Advanced CNC (Computer Numerical Control) machining is often employed for cutting and drilling, ensuring exact dimensions and hole alignment, critical for seamless on-site assembly. Welding processes adhere to strict international welding codes (e.g., ISO 3834 or AWS D1.1), with qualified welders performing the work. Post-welding, non-destructive testing (NDT) methods like ultrasonic testing or magnetic particle inspection may be used to detect any internal flaws in critical welds, ensuring the structural integrity of the paddle court frame.

Given that many padel court installations are outdoors, superior corrosion protection is paramount. This typically involves a multi-stage process:

Large sheets of raw glass are cut to precise dimensions, edges are polished, and holes for fasteners are drilled. The glass then undergoes a tempering process, where it's heated to over 600°C and rapidly cooled. This creates internal stresses that make the glass four to five times stronger than annealed glass and, importantly, causes it to shatter into small, blunt fragments upon impact, significantly reducing injury risk. Each tempered glass panel must pass fragmentation tests and often heat soak tests to reduce the risk of spontaneous breakage.

While turf is often sourced, its quality directly impacts playability. High-quality turf involves extrusion of fibers (monofilament or fibrillated), tufting onto a backing, and then coating the backing with latex or polyurethane for durability and stability. The density, pile height, and dtex (decitex, fiber thickness) are crucial parameters. FIP approval often requires specific turf characteristics for optimal ball bounce and player grip.

Components are often pre-assembled in modules at the factory to ensure fit and minimize on-site installation time and errors. A comprehensive final inspection covers dimensional accuracy, finish quality, and completeness of components. Packaging is designed to protect all parts during transit. Adherence to quality standards such as ISO 9001:2015 throughout the manufacturing cycle ensures a consistent, high-quality product.

By integrating these rigorous manufacturing processes and adhering to international inspection standards (like ISO and specific industry norms like FIP regulations or local building codes like ANSI standards for structural elements in some regions), manufacturers ensure the longevity, safety, and peak performance of every padel court, making them suitable for demanding environments like professional sports clubs, residential developments, hotels, and resorts. The focus on anti-corrosion treatments ensures suitability even in coastal or high-humidity environments.

The evolution of padel court design is driven by a quest for enhanced player experience, superior durability, and aesthetic integration. Modern courts incorporate several technical advantages and innovative features.

These advancements not only enhance the playing experience but also address operational concerns, offering solutions that are more durable, aesthetically pleasing, and economically viable over their extensive service life.

The versatility of padel court installations makes them suitable for a wide array of application scenarios, each benefiting from specific design considerations.

A high-performance padel court at a bustling sports club, designed for high traffic and optimal play.

Case Study Example: Luxury Resort Expansion in Coastal Region

A high-end resort located in a coastal area faced challenges with maintaining outdoor sports facilities due to salt corrosion and unpredictable weather. By installing two NO.5 padel court with separated roof structures, the resort achieved several critical objectives. The hot-dip galvanized and powder-coated steel structures, combined with the comprehensive roofing solution, provided unparalleled anti-corrosion protection and allowed for year-round operation, significantly boosting guest activity even during off-peak seasons. The aesthetically pleasing panoramic design of the courts also complemented the resort's luxurious ambiance, leading to overwhelmingly positive guest feedback and a measurable increase in ancillary revenue from court rentals and coaching. The use of specialized synthetic turf with advanced drainage also reduced maintenance needs, proving the long-term cost-effectiveness.

Selecting the right manufacturer for your padel court is a critical decision that impacts quality, longevity, and overall project success. B2B purchasers should evaluate potential partners based on several key criteria beyond just initial cost.

Tailored designs allow for seamless integration of the padel court into diverse architectural and environmental contexts.

By diligently vetting manufacturers based on these criteria, businesses can mitigate risks, ensure the acquisition of a superior padel court product, and secure a valuable long-term asset.

While standard padel court designs adhere to official dimensions, many projects require customized solutions to address specific site conditions, aesthetic preferences, or functional requirements. A reputable manufacturer will offer extensive customization capabilities.

Customization options can include:

The ability to provide bespoke solutions, backed by engineering expertise, ensures that the final padel court not only meets functional requirements but also seamlessly integrates into its environment, enhancing both utility and visual appeal. This level of customization is a hallmark of a professional B2B partner, offering significant long-term value.

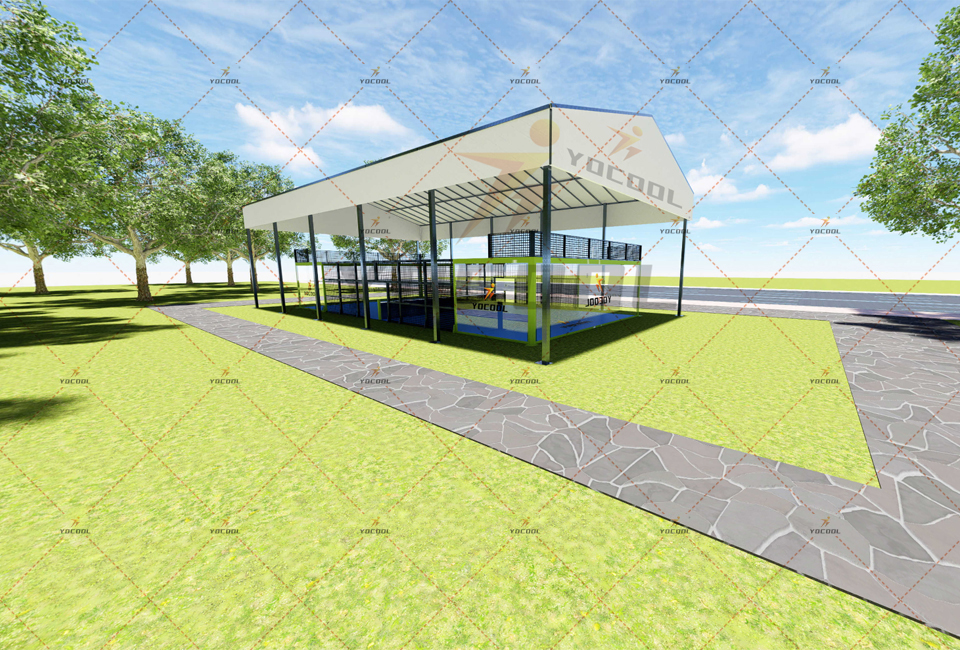

The NO.5 padel court with separated roof exemplifies innovative design for all-weather playability and structural elegance.

The NO.5 padel court with separated roof represents a premium offering in the market, meticulously engineered to provide an unparalleled playing experience combined with superior durability and versatility. This specific model addresses the growing demand for all-weather playability without compromising on aesthetic appeal or structural integrity.

Key features and advantages of the NO.5 model include:

The NO.5 padel court is an ideal investment for luxury hotels, upscale residential communities, private clubs, and high-volume sports centers seeking to provide a superior, all-weather paddle court solution that stands the test of time and delivers consistent revenue.

Building trust and demonstrating authority are fundamental pillars of our B2B engagement. Our commitment to excellence is reflected in every aspect of our operations, from design and manufacturing to delivery and after-sales support.

Our unwavering commitment to quality, transparency, and comprehensive client support makes us a reliable partner for your next padel court investment.

A: With proper maintenance and use of high-quality materials (galvanized steel, tempered glass, durable turf), a professional padel court can have a service life of 15-20 years for the main structure. The artificial turf typically needs replacement every 5-8 years depending on usage intensity, and LED lights may have a lifespan of 50,000 to 100,000 hours.

A: A solid, level foundation is crucial. Typically, a reinforced concrete slab (minimum 15-20 cm thick) or a perimeter concrete beam with a compacted aggregate base is required. Proper drainage provisions are also essential to prevent water accumulation and ensure the longevity of the court and its components. We provide detailed foundation plans.

A: Yes, panoramic padel court designs often involve slightly higher costs due to the larger, thicker glass panels and specialized structural design to minimize vertical supports. However, their benefits include enhanced aesthetics, superior spectator visibility (ideal for events or live streaming), and a more premium feel, which can attract more players and higher court rental fees.

A: Regular maintenance includes sweeping/brushing the artificial turf to redistribute sand infill and remove debris, checking the glass and mesh for damage, inspecting the net, and ensuring lighting systems are functioning. Annual deep cleaning and infill top-ups for the turf are recommended to maintain optimal playability and extend turf life. Our courts are designed for low maintenance, thanks to high-quality anti-corrosion treatments and durable materials.

A: After the foundation is ready, the installation of a single padel court typically takes 3-7 days for a professional team, depending on the complexity of the court (e.g., standard vs. covered court) and site conditions. The NO.5 padel court with separated roof may take slightly longer due to the roof structure. Our modular designs aid in efficient assembly.

The burgeoning popularity of padel presents a compelling investment opportunity for B2B entities. From sports clubs and residential developers to hospitality providers, the strategic integration of high-quality padel court facilities can unlock significant value. By prioritizing robust construction, adherence to international standards, and innovative designs like the NO.5 padel court with separated roof, stakeholders can ensure long-term operational success and a premium user experience. The emphasis on advanced materials, precise manufacturing, comprehensive quality control, and dedicated after-sales support ensures that these courts are not merely recreational assets but durable, high-performing investments. As the sport continues its global expansion, partnering with an experienced and authoritative manufacturer capable of delivering bespoke, future-proof solutions is paramount for capitalizing on this dynamic market.

This is the last article

Premium Padel Courts: Panoramic Designs & Custom Builds

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort

Premium Padel Court Solutions & Panoramic Designs

High-Performance Paddle Racquets for Padel & Paddle Courts