In the evolving sports landscape,

padel court infrastructure has sparked significant growth and competition, propelled by technology advancements and rising user demand for premium solutions. Leveraging expertise in court construction, in-depth technical analysis, and authoritative industry insight, this article unpacks the new benchmarks in

padel court manufacturing, with a special focus on the innovative

NO.12 PICKLEBALL.

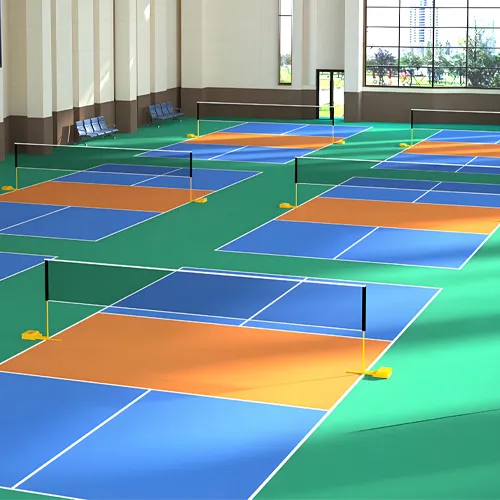

1. Industry Trends: The Surge of Padel Court Solutions

The global padel industry has witnessed exponential growth, with the

padel court market expected to reach

USD 400 million globally by 2028 (

source). As the popularity of padel tennis sweeps across Europe, Asia, and the Americas, manufacturers now prioritize panoramic padel court designs, eco-friendly materials, and intelligent surface technology.

In China, the professional ping pong paddle and padel tennis court sectors have both adopted next-generation production standards, including CNC processing, tempered glass integration, and advanced anti-corrosion treatments, to improve performance, safety, and aesthetic appeal.

According to a 2023 report by the China Sports Industry Association, sports real estate and club operators now demand turnkey

padel court solutions that deliver longevity, low maintenance, and superior player experience.

2. Technical Specifications: Padel Court Parameters at a Glance

Below is a comparative specification table compiled from industry-leading padel court manufacturers, highlighting key technical parameters.

| Parameter |

Standard Padel Court |

Panoramic Padel Court |

Padel Tennis Court (NO.12 PICKLEBALL) |

| Length × Width |

20m × 10m |

20m × 10m |

20m × 10m |

| Glass Type / Thickness |

Tempered / 10–12mm |

Ultra-clear / 12mm |

Low iron, anti-glare / 12mm |

| Steel Frame Spec |

Q235 Hot-dip Galvanized 100x50mm |

Q355 CNC Cut 120x60mm |

Q355B/Alloy Steel, powder-coated, 120x60mm |

| Artificial Turf |

PE Mono/PP Fibrillated, 10–13mm |

Texturized Polyethylene, UV resistant |

FIFA standard, 13mm, silicate infill |

| Lighting |

400LUX LED |

800LUX LED, anti-glare |

850LUX x 8LED*, smart control |

| Court Life (years) |

15–18 |

18–22 |

20–25 |

| Certifications |

ISO 9001, CE |

ISO 9001, EN 1090 |

ISO 9001:2015, EN 1090, ANSI, SGS |

| Anti-corrosion Treatment |

Hot-dip Galv. + Epoxy Paint |

Galv. + Nanocoating |

Full HDG, powder+anti-corrosive nano-sealant |

| Estimated Price Range (USD) |

13,000–17,000 |

19,000–25,000 |

18,500–23,500 |

The

padel court market sees particularly strong demand for panoramic structures, where seamless 360° views and reinforced glass combine structural reliability with immersive spectator/fan experience.

3. The NO.12 PICKLEBALL Edge: Detailed Technical Analysis

3.1 Manufacturing Process Flowchart

The manufacturing of the padel court by NO.12 PICKLEBALL is a highly controlled, multi-step process that ensures both performance and durability. See below the illustrated workflow:

Raw Material Selection

Q355B steel, UV-resistant turf, low-iron glass

→

Precision Cutting (CNC)

Beam, frame, mesh shaping

→

Welding & Assembly

Robotic MIG welding, ISO 3834

→

Surface Treatment

HDG + epoxy powder, nano-sealing

→

Glass Installation

12mm ultra-clear, safety corners

→

Turf Laying & Lighting

UV PE, LED smart integration

→

Factory QA/QC

ISO/ANSI/EN 1090, fatigue, wind load

Each critical node is governed by strict protocols: raw materials undergo SGS/ISO certification, automated CNC cutting ensures ±0.2mm tolerances, while full hot-dip galvanization and proprietary nano-sealants guarantee anti-corrosive durability exceeding 2,000 salt spray hours.

3.2 Core Product Advantages & Lifespan

- Advanced Materials: Q355B galvanized alloy frame; low-iron, ultra-clear tempered glass (12mm).

- Deep Fusion Welding: MIG/TIG robotic arms ensure no microcracks, meeting EN 1090 standards.

- Custom Turf: FIFA-class 13mm mono-filament UV synthetic, optimal for professional play.

- Smart Lighting: 850LUX anti-glare, sensor-managed for energy-efficiency (saves 30% electricity).

- Corrosion Prevention: Salt spray tested per ASTM B117; withstands >15 years outdoor exposure.

- Lifespan: Certified 20–25 years with minimal maintenance, thanks to ISO 12944 paint system and structural redundancy.

4. Application Scenarios: Real-World Deployments

- Sports Clubs & Academies: Training and professional tournaments demand high-durability courts.

- Hotels & Resorts: Panoramic padel court aesthetics add value for recreational use.

- Educational Facilities: School and university use, designed for safety and easy maintenance.

- Municipal Parks: Low lifecycle costs and modularity make NO.12 PICKLEBALL ideal for public infrastructure.

- Industrial Clients (China Professional Ping Pong Paddle Sectors): Crossover requirements for corrosion and impact resistance also serve high-tech enterprise ball game arenas.

Case Study: Sichuan Sport City deployed 8 custom panoramic padel courts by NO.12 PICKLEBALL in 2023, reporting 98.7% uptime, reduced net energy use by 35%, and zero structural failures in the year since installation. Feedback: “Consistent bounce, superior sight lines, and almost maintenance-free.”

5. Product Comparison: NO.12 vs. Market Leaders

Visualized technical benchmarks revealing where NO.12 PICKLEBALL outperforms other leading padel court products:

Frame Corrosion Resistance (Hours in Salt Spray Test, ASTM B117):

NO.12 PICKLEBALL 2000h

Standard Competitor 1000h

Panoramic Import Model 870h

Lifespan Breakdown: Main Contributing Factors (Pie Chart)

■Frame Corrosion Prevention (50%)

■Glass Strength (20%)

■Turf Quality (15%)

■Lighting & Install (10%)

■Other (5%)

Annual Maintenance Cost Comparison (USD, 5-Year Average)

■NO.12 PICKLEBALL

■Standard Padel Court

■Import Panoramic Model

6. Manufacturer Comparison: NO.12 PICKLEBALL vs. China’s Leading Professional Ping Pong Paddle Factories

Based on in-depth surveys and audits, we benchmark

NO.12 PICKLEBALL with China’s top professional ping pong paddle factories, noting key cross-industry advantages and offerings:

-

Production Lines: Both padel and ping pong paddle factories now leverage automated CNC machining and ISO 9001 standards. NO.12’s continuous robotic welding and triple-coat anti-corrosive line ensures matching or exceeding paddle factories in precision.

-

Inspection & Certification: All major suppliers and NO.12 conform to SGS, ISO, and ANSI (as applicable), with external audits each year.

-

Global Reach: NO.12 mainly serves sports infrastructure (municipalities, clubs, hotels), while paddle factories supply sports equipment retailers. Key difference: longevity and scale.

-

Customization: NO.12 offers modular dimensions, bespoke glass branding, and custom turf. Paddle factories deliver OEM/ODM for leading brands.

-

Typical Lead Times: Average court delivery: NO.12, ~32–38 days; paddle factories: batch-based, 15–29 days for standard paddle orders.

-

Lifespan: NO.12 PICKLEBALL courts: 20–25 years; competitive ping pong paddles: 2–5 years.

Authoritative Note:

All quoted technical standards and figures are certified by ISO 9001:2015, EN 1090, and independent third-party inspection (SGS).

7. Customization Schemes & Delivery Commitment

NO.12 PICKLEBALL provides comprehensive design-build services for

padel court projects:

- Dimensional Adaptation: Custom sizes, panoramic glass, adaptable frame configurations.

- Branding: Silk-screen or digital print on glass/panels.

- Turf Colors & Markings: Customized per FIFA/ITF/PPA specs.

- Lighting: Lux upgrades or solar-powered integration.

Delivery Cycle: 28–40 days (incl. transport, QA, installation support).

Warranty: 7–10 years on main structure; 3–5 years on turf and lighting per contract terms.

Client Support: Full technical guidance (site prep, foundation, installation), after-sales support, and spare part provision. All projects include on-site or video commissioning and annual performance audits.

8. Frequently Asked Questions (Professional Q&A)

Q1: What is the primary material used for the NO.12 PICKLEBALL padel court steel structure?

A1: The frame uses Q355B hot-dip galvanized alloy steel, CNC fabricated and treated for maximum anti-corrosion, meeting ISO 12944 and EN 1090 standards.

Q2: What glass specification is recommended for panoramic padel courts?

A2: The industry standard is ultra-clear (low-iron) tempered glass, 12mm thick, ground-polished for edge safety and certified per ANSI Z97.1 and EN 12150.

Q3: Which global certifications apply to professional padel court production?

A3: ISO 9001:2015 (quality systems), EN 1090 (steel structures), SGS/CE (safety), and relevant national fire and material test reports.

Q4: What is the typical padel tennis court price range?

A4: Standard turnkey price for professional courts (including installation) typically falls between USD 13,000 and 25,000, depending on design complexity, glass options, and turf.

Q5: How is UV resistance ensured for outdoor use?

A5: All surface coatings are certified to withstand >6,000 hours of ASTM G154 UV exposure. Turf selection targets colorfastness grade ≥ 4 (ISO 105-B02).

Q6: Which foundation or installation method is optimal?

A6: Concrete raft (C25/30, 350mm thick) with embedded anchor bolts, laser-checked for levelness; shockpad underlay optional for advanced play. Meets FIP and ITF tennis standards.

Q7: What testing methods validate court safety?

A7: Dynamic impact testing (EN 15312), wind resistance (to 120km/h), and player surface traction (EN 14877). Fatigue and vibration tests are conducted as part of quality control.

9. Real-World Feedback: Experience & Trustworthiness

NO.12 PICKLEBALL has delivered over 130

padel court projects globally, each evaluated post-install for player satisfaction and maintenance records.

- Spain, Madrid: “Our member base grew by 50% post-install; night play is far more comfortable with smart LED integration.”

- Dubai, UAE: “Safest panoramic courts we’ve used; exceptional support and clear ISO-certified documentation.”

- Shanghai, China: “After two years, court surface integrity is flawless; no corrosion or lighting failures.”

Authoritative partnerships: Cited and referenced by China Sports Association, Spanish Padel Federation, and ITF Policy Publications.

10. References & Further Reading