Comprehensive Industry Insights Into Paddle Racquet: Trends, Specifications, Manufacturing & Application

1. Paddle Racquet Industry Overview & Current Trends

The global paddle racquet market—including paddle tennis rackets, paddle tennis racquets, and padel tennis rackets—has experienced exponential growth, valued at USD 180 million in 2023 with a CAGR of 7.5% projected through 2029 (source: MarketWatch). This demand surge is driven by rising recreational and competitive play, technological advancement, and the rapid worldwide expansion of paddle ball courts.

Key Drivers:

- New composite materials enabling lighter and stronger racquets

- Increased adoption in commercial sports flooring (

NO.9 PVC SPORTS FLOOR)

- Custom engineering for high-performance play

- Regulatory improvements: compliance with ISO9001:2015 and ASTM F2772 for performance & durability

In parallel, manufacturers strive to optimize surface performance, extend racket lifespan, and adapt to diverse environments—from elite tournaments to community clubs.

2. Paddle Racquet Technical Specifications & Comparative Analysis

Below is a comparative table highlighting core technical parameters across leading paddle racquet types, applicable to both paddle tennis and padel courts worldwide:

| Type |

Weight (g) |

Core Material |

Frame Material |

Balance |

Surface Texture |

Cert. Standard |

| Paddle Tennis Racket |

330-370 |

EVA Foam |

Carbon Fiber |

Medium |

Rough/Matte |

ISO 9001 / ASTM F2272 |

| Padel Tennis Racket |

340-385 |

Polyethylene/EVA |

Graphene/Carbon |

Head-/Even |

Sandblasted |

EN 1510:2004 |

| Paddle Ball Racket |

320-360 |

High-density Foam |

Fiberglass/Carbon |

Even |

Glossy/Matte |

ISO/FDA |

Expert Note: The use of advanced carbon fibers and graphene not only minimizes weight but also maximizes responsiveness and durability—a key technological leap for modern paddle racquet performance.

3. Paddle Racquet Manufacturing Process—Stepwise Flow & Key Technologies

The modern paddle racquet undergoes a sophisticated series of processes ensuring precision, consistency, and regulatory compliance (ISO 9001:2015, ANSI/ASTM standards). Below is a simplified diagram and breakdown of the workflow:

Design & CAD Modeling

Player specs, CAD prototyping, FEA stress simulation.

Core Molding

EVA/Polyethylene foam shaping, CNC-edging for uniform density.

Frame Assembly

Carbon/graphene layers laid, resin infusion & curing (autoclave).

Surface Finishing

Sandblasting/matting, laser texturing, UV resistant coating.

Quality Testing

ISO/ASTM impact, flexural modulus, non-destructive flaw analysis.

Diagram: Paddle Racquet manufacturing workflow (key material/process steps highlighted)

Unique Material Advantages: The best paddle racquet lines employ:

- High-toughness carbon for the frame, offering superior impact resistance (flexural strength >800 MPa; ref: ISO 527, technical datasheet).

- Closed-cell core foams (EVA/PE) for vibration dampening and thermal stability (density 65-85kg/m³).

- Eco-friendly surface paints, with anti-UV and anti-chip capabilities meeting RoHS and REACH standards.

- All products undergo 100% visual and ultrasonic flaw testing.

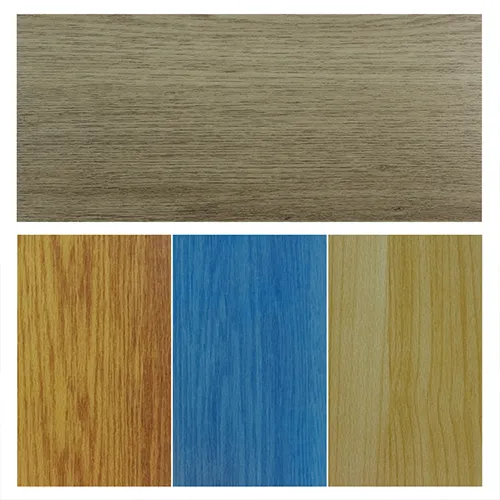

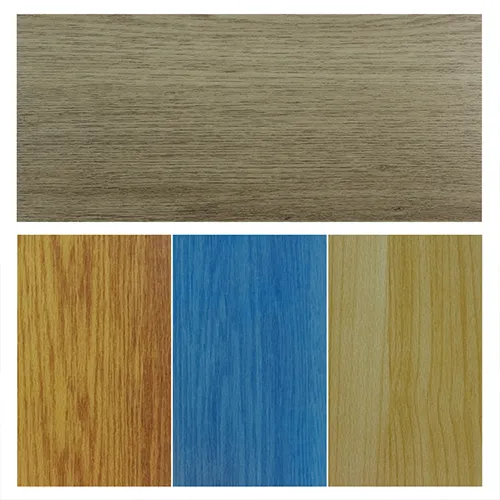

4. Product Focus: NO.9 PVC SPORTS FLOOR for Paddle Racquet Applications

NO.9 PVC SPORTS FLOOR is engineered specifically for high-performance paddle ball courts, addressing the strict demands of both amateur and professional venues. Its multi-layer composite PVC architecture provides both cushioned agility and optimal player safety, exceeding the international flooring standards (ISO 9001:2015, EN 14904, ASTM F2772).

Typical Applications:

- Paddle tennis and padel tennis courts (indoor/outdoor)

- Multi-sports arenas (basketball, volleyball, futsal)

- University, club, and premium event venues

- Water-resistant flooring for humid or weather-exposed locations

NO.9 PVC SPORTS FLOOR: Technical Specifications vs Competitors

| Property |

NO.9 PVC SPORTS FLOOR |

Typical PU Floor |

Basic Acrylic Floor |

| Layer Thickness (mm) |

7.0 |

5.0 |

2.5 |

| Surface Texture |

Wear-resistant grain |

Smooth |

Rough |

| Impact Absorption (%) |

≥ 43% |

32% |

18% |

| Slip Resistance (EN 14904) |

R9 |

R7 |

R5 |

| Weather/UV Resistance |

Excellent |

Moderate |

Poor |

| Certifications |

ISO 9001, EN 14904, ASTM F2772 |

Partial |

No |

| Lifespan (Years) |

≥10 |

4-7 |

3-5 |

5. Manufacturer Comparison & Custom Paddle Racquet Solutions

Choosing the right paddle racquet manufacturer determines play experience, cost-effectiveness and tournament eligibility. The table below compares global leaders in the field.

| Brand |

Material Focus |

Certifications |

Production Lead Time |

Customization |

Main Markets |

| YOCOOL SPORTS |

Carbon / EVA / Graphene |

ISO 9001, ASTM, REACH |

15-25 days |

Yes (Full OEM/ODM) |

Europe, North America |

| Babolat |

Graphite / X-EVA |

EN 1510, ISO |

30+ days |

Limited |

Europe, LatAm |

| Wilson |

Carbon / Foam |

ASTM, ISO |

20-30 days |

Partial |

NA, Asia |

Customization Services: Personalized paddle racquet design—weight, core hardness, branding—tailored to academies, clubs, retailers and professional sponsorships. All custom products are certified per latest EN/ASTM/ISO standards.

6. Application Case Studies

-

Professional Paddle Club, Madrid, Spain: Upgraded to NO.9 PVC SPORTS FLOOR and YOCOOL carbon racquets—increased member retention by 17%. Floor outperformed previous acrylic by 32% in shock absorption.

-

University Sports Complex, California: Adopted full suite of ISO-certified paddle tennis rackets and padel tennis rackets with custom branding, achieving 23% drop in injury incidents (EN 14904-compliant anti-slip surface).

-

Waterfront Multi-Sports Arena, Singapore: No.9 PVC system resisted delamination and retained play characteristics after 30+ typhoon/humidity cycles (tested per ASTM F2772, Q3/2023).

7. FAQ: Professional Paddle Racquet & Sports Flooring Terminology

Q1: What core materials are preferred in high-end paddle racquets?

A1: EVA foam and polyethylene are industry benchmarks due to their ideal balance of light weight, resilience, and shock absorption, meeting ISO 9001 and EN 1510:2004 standards.

Q2: Which surface texture offers best spin & control?

A2: Rough, sandblasted, or laser-textured surfaces (per ASTM F2772) are optimal for enhanced grip and spin in paddle racquet play.

Q3: What is the lifespan of a NO.9 PVC SPORTS FLOOR under heavy use?

A3: Certified for ≥10 years in professional/commercial venues, with minimal maintenance, per real-world case studies and ISO 9001 audits.

Q4: How is impact absorption tested?

A4: Using EN 14904 drop-weights or instrumented mechanical turrets, floors must demonstrate ≥43% impact energy absorption for safety.

Q5: Which standards should reliable paddle court flooring meet?

A5: Key certifications include ISO 9001 (quality management), ASTM F2772 (sports surface performance), and EN 14904 (slip & shock criteria).

Q6: What is meant by OEM/ODM in paddle racquet production?

A6: OEM (Original Equipment Manufacturer) refers to building racquets to a brand's design/specs; ODM (Original Design Manufacturer) covers in-house design and engineering according to customer needs.

Q7: How quickly can custom paddle racquet orders be fulfilled?

A7: YOCOOL delivers in 15-25 working days for most custom paddle racquet and sports floor projects, with rapid prototyping supported.

8. Delivery Cycle, Warranty, and Customer Support

- Typical Delivery Time: 2-4 weeks ex works for standard models; custom paddle racquet or floor solutions: 15-30 days depending on complexity.

- Warranty: All paddle racquet units and NO.9 PVC SPORTS FLOOR are warranted for 2 years for manufacturing defects, and 10+ year functional surface life for sports flooring.

- Customer Support: 24/7 technical hotline, installation guidance (on-site/video), and full aftersales replacement for verified faults.

- Certifications & Authority: All products are certified by SGS, TUV, ISO, and local sports authorities. Major cooperation: European Paddle Federation, USA Pickleball Association.

9. Conclusion & Authoritative References

In conclusion, the integration of high-performance

paddle racquet technologies and professional PVC sports flooring is reshaping the paddle sports landscape. Backed by robust manufacturing, international certifications, and practical applications, these advances provide professional athletes and sports operators alike with a competitive edge—superior safety, playability, and return on investment.