The global phenomenon of padel court construction is experiencing an unprecedented boom, transforming urban landscapes and sports facilities worldwide. This dynamic sport, a hybrid of tennis and squash, demands specialized infrastructure designed for optimal performance, player safety, and durability. As the sport gains traction, so does the demand for high-quality, innovative court solutions, including advanced designs like the panoramic padel court and the versatile padel tennis court. Understanding the intricate details of a paddle court, from its foundational materials to its advanced manufacturing processes, is crucial for investors, facility managers, and enthusiasts alike.

Industry Trends and Growth Dynamics

The padel court market is characterized by robust growth, driven by increasing participation rates, celebrity endorsements, and strategic investments in sports infrastructure. According to a recent report by the International Padel Federation (FIP), player numbers have surged, with millions now actively engaging in the sport across five continents. Europe, particularly Spain, Italy, and Sweden, leads the charge, but rapid expansion is observed in North America, the Middle East, and Asia. This growth fuels a demand for diverse court types, from standard models to premium panoramic padel court designs that offer an unobstructed view, enhancing spectator experience and court aesthetics. The trend towards integrated sports complexes and residential developments incorporating paddle tennis court facilities highlights the sport's appeal as a lifestyle choice.

Technological advancements in material science and construction techniques are also shaping the industry. Manufacturers are increasingly focusing on sustainable materials, energy-efficient lighting solutions, and modular designs that facilitate quicker installation and relocation. The drive for greater playing comfort and safety pushes innovations in synthetic turf quality, shock absorption layers, and robust, yet aesthetically pleasing, structural elements. The integration of smart features, such as booking systems and performance tracking, further modernizes the padel court experience.

Technical Parameters of a Standard Padel Court

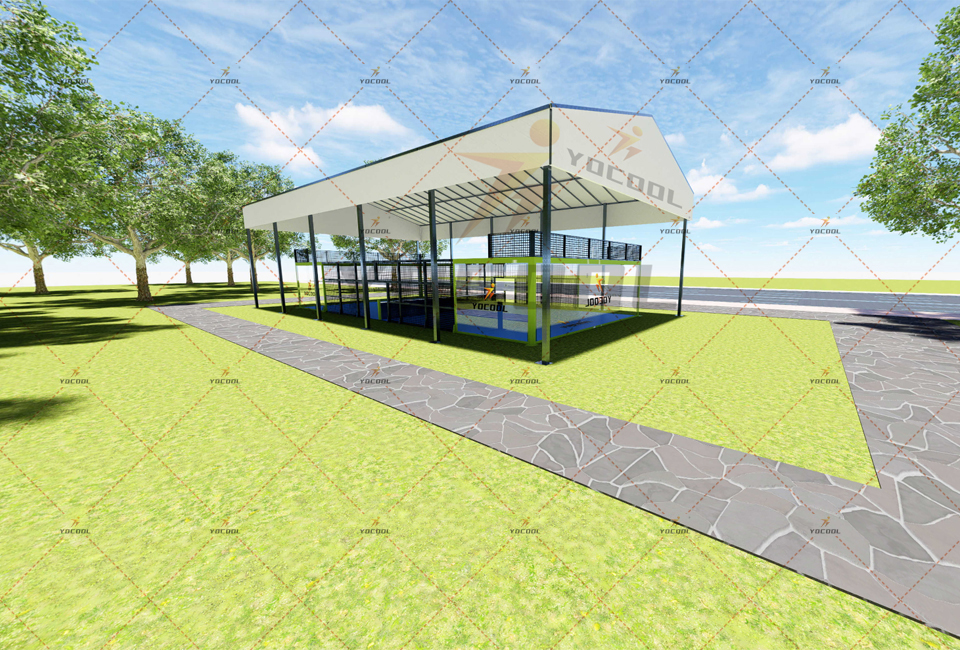

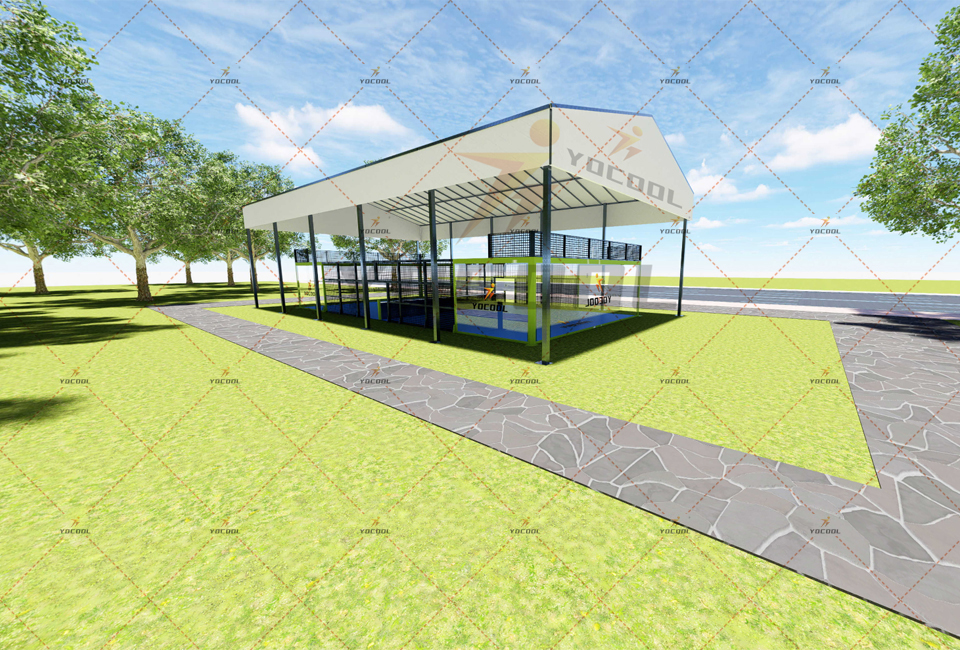

A standard padel court adheres to precise dimensions and material specifications to ensure fair play and structural integrity. Key components include the playing surface, glass walls, metallic mesh fencing, and lighting systems. The NO.5 padel court with separated roof, a flagship product, exemplifies cutting-edge design, integrating these elements with innovative roofing solutions.

Padel Court Component Specifications:

| Component |

Standard Specification |

NO.5 Padel Court Enhancement |

| Court Dimensions (Internal) |

20m (length) x 10m (width) |

Standard FIP dimensions for professional play. |

| Glass Walls |

12mm tempered safety glass, typically 3m high at back walls, 2m high at side walls. |

High-impact 12mm tempered safety glass, compliant with EN 12150-1, providing exceptional transparency and durability for a panoramic padel court feel. |

| Metallic Structure |

Galvanized steel, typically 80x80x2mm or 100x50x2mm profiles. Powder-coated finish. |

Heavy-gauge galvanized steel (e.g., 100x100x3mm structural pillars), double electrostatic powder coating for superior corrosion resistance and longevity. Meets ISO 9227 salt spray test standards. |

| Mesh Fencing |

Electro-welded mesh, typically 50x50x4mm. |

Reinforced 50x50x4mm electro-welded mesh, anti-climb design, securely integrated into the steel frame to prevent vibration and ensure consistent ball rebound. |

| Playing Surface (Turf) |

Monofilament or fibrillated synthetic turf, 10-12mm pile height, sand infill. |

Premium fibrillated or textured monofilament synthetic turf, 12mm pile height, certified by FIBA or equivalent for sports performance and shock absorption (e.g., DIN 18032-7). Optimized for excellent ball bounce and player comfort. |

| Lighting |

4-8 LED floodlights, 200-300W each, 500-700 lux at court level. |

Energy-efficient LED lighting system (e.g., 8 x 250W LED projectors), providing uniform illumination (min. 700 lux) with anti-glare technology, reducing light pollution and operational costs. |

| Roof Structure (for NO.5) |

N/A for standard outdoor courts. |

Independent structural steel framework with high-strength PVC membrane or polycarbonate roofing panels. Designed for superior weather protection, UV resistance, and optimal light transmission, allowing year-round play without direct sun exposure. Engineered to withstand specific wind loads and snow loads (e.g., EN 1991-1-4 for wind actions). |

These specifications underline the precision engineering required for a professional-grade padel court. The NO.5 padel court with separated roof specifically addresses the challenges of outdoor installations, offering unparalleled protection against elements while maintaining an open, airy feel.

Application Scenarios and Technical Advantages

The versatility of a padel court allows for its integration into various environments, from bustling urban centers to serene residential complexes. Common application scenarios include:

- Commercial Sports Clubs: Providing state-of-the-art facilities that attract members and generate revenue. The NO.5 padel court with separated roof enhances the club's offering by guaranteeing play regardless of weather.

- Hotels and Resorts: Enhancing guest experience and property value through premium recreational amenities. A panoramic padel court is particularly appealing in scenic locations.

- Residential Communities: Offering exclusive sports facilities to residents, fostering community engagement and boosting property desirability.

- Public Parks and Municipalities: Promoting public health and sports participation, providing accessible facilities for citizens.

- Private Residences: For dedicated enthusiasts seeking a personal paddle court for leisure and training.

Technical Advantages of the NO.5 Padel Court with Separated Roof:

Our NO.5 padel court is engineered to deliver superior performance and longevity, addressing critical aspects of sports facility management:

- All-Weather Playability: The separated roof structure provides effective shelter from rain, intense sun, and light snow, ensuring continuous playability and maximizing court utilization. This significantly increases ROI for commercial operators.

- Enhanced Durability & Corrosion Resistance: All steel components undergo a multi-stage anti-corrosion treatment, including hot-dip galvanization and dual-layer electrostatic powder coating. This rigorous process adheres to ISO 12944 standards for C5-M (very high corrosivity environments), extending the court's lifespan beyond 15-20 years even in coastal or humid regions.

- Optimal Lighting and Glare Reduction: The roof's design can incorporate translucent materials that diffuse natural light, reducing glare on sunny days. Combined with precisely positioned LED lighting, it ensures consistent, shadow-free illumination crucial for players tracking a fast-moving paddle racquet and ball.

- Superior Player Comfort: The independent roof structure minimizes heat build-up under direct sunlight, creating a more comfortable playing environment. The high-quality synthetic turf offers excellent shock absorption, reducing stress on joints and enhancing player safety.

- Low Maintenance Requirements: The robust construction materials and finishes reduce the need for frequent repairs or repainting. The tempered glass is easy to clean, and the turf requires minimal upkeep, contributing to lower operational costs over the court's life.

- Structural Soundness & Safety: Engineered to withstand significant wind loads (e.g., up to 160 km/h) and seismic activity, ensuring player safety and structural integrity under various environmental conditions. All connections are reinforced, and safety standards like ASTM F1936 for playground equipment are considered where applicable for player-contact elements.

Manufacturer Comparison and Differentiation

The market for padel court manufacturers is competitive, with varying levels of quality, customization, and after-sales support. When evaluating suppliers for a paddle tennis court, key differentiators emerge:

Key Factors for Manufacturer Comparison:

| Factor |

Standard Manufacturer |

Yocoolcn (NO.5 Padel Court) |

| Material Quality & Sourcing |

Standard steel, basic galvanization, generic glass. |

Premium-grade structural steel (Q235/Q345), hot-dip galvanization (min. 80 micron zinc), AkzoNobel or Jotun powder coating, top-tier 12mm tempered safety glass from certified suppliers (e.g., Saint-Gobain equivalent). |

| Manufacturing Process |

Standard welding, manual coating, minimal QC. |

Automated CNC machining for precision cutting and drilling, robotic welding for consistent joints, multi-stage surface treatment (acid pickling, phosphating, hot-dip galvanizing, double electrostatic powder coating), strict ISO 9001:2015 certified quality control at every stage. |

| Design & Engineering |

Basic templates, limited customization. |

In-house R&D team for innovative designs (like separated roof), structural engineering validated by third-party certifiers for wind/snow loads, detailed CAD drawings, BIM integration for complex projects. |

| Customization Options |

Color, turf type. |

Extensive customization: court dimensions, roof design, panoramic options, branding integration, specific lighting solutions, access controls, specialized turf systems, auxiliary structures (e.g., changing rooms). |

| Certifications & Compliance |

Few or none specific to sports infrastructure. |

ISO 9001 (Quality Management), ISO 14001 (Environmental Management), OHSAS 18001 (Occupational Health & Safety). Adherence to FIP (International Padel Federation) regulations, relevant EN (European Norms) and ASTM (American Society for Testing and Materials) standards for materials and sports surfaces. |

| Warranty & After-Sales |

1-2 years structural warranty, limited support. |

5-10 year structural warranty, 2-5 year warranty on other components. Dedicated after-sales team, spare parts availability, remote technical support, optional on-site maintenance contracts. |

| Project Management & Installation |

Customer manages, or basic guidance. |

Full project lifecycle support: site assessment, detailed planning, foundation design guidance, professional installation teams, post-installation checks, training for facility staff. |

Our commitment to excellence is reflected in our robust manufacturing process and adherence to international standards. For instance, the steel structures for the NO.5 padel court undergo a meticulous process: precision cutting via CNC laser machines, robotic welding ensuring uniform seam quality, followed by hot-dip galvanization according to ASTM A123 standards. This is then complemented by an electrostatic powder coating, often using brands like AkzoNobel, for a superior finish and added corrosion protection. This multi-layered approach ensures that every padel court we deliver withstands the test of time and intensive use.

Customization Solutions and Integration

Recognizing that each project has unique requirements, Yocoolcn offers comprehensive customization solutions for every padel court. Beyond standard dimensions and colors, we provide tailored designs that integrate seamlessly with existing architectural styles and specific operational needs. Whether it's a multi-court complex for a professional club or a single paddle court for a private estate, our team works closely with clients from conceptualization to completion.

- Architectural Integration: Designing court structures that complement surrounding buildings or landscapes, including material finishes, lighting aesthetics, and overall footprint.

- Branding and Aesthetics: Customizing court colors, mesh designs, and even glass panel etching to incorporate club logos, sponsorship branding, or specific visual themes, enhancing the visual appeal of the panoramic padel court.

- Accessibility Features: Incorporating ramp access, wider gates, or specific seating areas to ensure the padel court is accessible to all players and spectators, adhering to ADA compliance where applicable.

- Ancillary Facilities: Assisting in the design and integration of adjacent facilities such as changing rooms, spectator stands, pro shops, and automated booking kiosks, creating a complete sports experience.

- Smart Technology Integration: Offering solutions for automated LED lighting control, integrated sound systems, CCTV surveillance, and advanced court booking software, streamlining operations for any padel tennis court.

Our design flexibility ensures that whether you require a compact urban solution or a sprawling multi-court complex, the final product will be a bespoke, high-performance padel court tailored to your vision and budget.

Craftsmanship Process: From Concept to Court

The manufacturing of a high-quality padel court is a complex process demanding precision engineering, robust material selection, and rigorous quality control. Our NO.5 padel court with separated roof undergoes a meticulous multi-stage production journey:

1. Design and Engineering (Concept & CAD/BIM):

- Initial client consultation to understand specific requirements, site conditions, and desired aesthetics.

- Our in-house design team, comprising structural engineers and sports facility specialists, develops detailed CAD drawings and 3D models. This includes structural analysis for wind loads, seismic activity, and material stress (finite element analysis - FEA).

- For the separated roof, detailed structural calculations are performed to ensure its independence and stability, considering snow loads, wind uplift, and rainwater drainage.

- All designs adhere to FIP regulations and relevant international building codes.

2. Material Procurement & Quality Assurance:

- Steel (Structure): We source high-grade structural steel (e.g., Q235 or Q345, equivalent to ASTM A36) from certified mills. Each batch undergoes chemical composition analysis and mechanical testing (tensile strength, yield strength) to ensure compliance.

- Glass (Walls): 12mm tempered safety glass is procured from reputable manufacturers. Each panel is tested for impact resistance (e.g., EN 12150-1 fragmentation test) and optical clarity.

- Synthetic Turf (Playing Surface): Premium monofilament or fibrillated turf rolls are sourced from leading suppliers, tested for pile height, density, UV stability, and slip resistance (e.g., EN 14877 for synthetic sports surfaces).

- Powder Coating: We utilize high-performance outdoor-grade polyester powder coatings from industry leaders like AkzoNobel or Jotun, ensuring color stability and superior corrosion protection.

3. Fabrication of Steel Structure (Precision & Durability):

-

Cutting & Drilling: Steel profiles are cut to exact dimensions using CNC laser cutting machines, ensuring unparalleled precision and smooth edges. Holes for bolt connections are drilled with automated CNC machines to guarantee alignment.

→ Key Note: CNC processing minimizes human error and ensures repeatable accuracy for all frame components, crucial for swift on-site assembly.

-

Welding: Structural connections are primarily executed using robotic welding (MIG/MAG welding) for consistent, high-strength welds. Manual welding is used for specialized joints, performed by certified welders (e.g., AWS D1.1 certified). All welds undergo non-destructive testing (NDT) such as ultrasonic testing or magnetic particle inspection to detect any flaws.

→ Key Note: Robotic welding ensures uniform bead penetration and reduces distortion, contributing to the overall structural integrity of the padel court.

-

Hot-Dip Galvanization: Following fabrication, all steel components are immersed in a molten zinc bath (450°C). This process creates a metallurgical bond between steel and zinc, providing a robust, long-lasting anti-corrosion barrier (min. 80 microns thick), compliant with ISO 1461 or ASTM A123. This is critical for the longevity of an outdoor padel court, especially in humid or coastal environments.

→ Key Note: Hot-dip galvanization offers cathodic protection and an impenetrable barrier, far superior to paint or spray-on coatings for long-term corrosion resistance.

-

Powder Coating: After galvanization, components undergo a surface preparation (degreasing, phosphating) and then an electrostatic powder coating. The powder is cured in an oven at specific temperatures (e.g., 200°C) to form a durable, aesthetically pleasing finish that offers an additional layer of protection against UV, scratches, and minor abrasions. This process contributes to the overall aesthetic of the paddle court.

→ Key Note: Dual-layer protection (galvanization + powder coating) significantly extends the lifespan and maintains the visual appeal of the court, reducing maintenance needs.

4. Glass Tempering and Mesh Manufacturing:

- Glass panels are precisely cut, drilled, and then tempered in a specialized furnace. Tempering heats the glass to over 600°C and then rapidly cools it, increasing its strength by 4-5 times compared to annealed glass. In the event of breakage, it shatters into small, blunt pieces, significantly reducing injury risk.

- The metallic mesh fencing is electro-welded using high-tensile steel wire. Each mesh panel is then hot-dip galvanized and powder-coated, similar to the main structure, ensuring consistent anti-corrosion properties and aesthetic harmony with the rest of the padel court.

5. Pre-Assembly & Final Quality Inspection (QCI):

- Key structural components are pre-assembled in the factory to ensure perfect fit and alignment before shipment.

- A comprehensive Quality Control Inspection (QCI) is performed on all fabricated parts, verifying dimensions, surface finishes, welding quality, and adherence to design specifications. This final check ensures that all components for the padel court meet our stringent quality benchmarks before packaging.

- Each component is carefully packed to prevent damage during transit, using robust protective materials.

6. Logistics & Installation:

- Components are shipped to the client's site.

- Our experienced installation teams (or certified local partners) assemble the padel court according to detailed construction manuals and engineering drawings. This includes foundation preparation, frame assembly, glass and mesh installation, turf laying, and lighting setup. The separated roof structure is installed independently, ensuring its structural integrity does not rely on the court frame itself.

This detailed process ensures that every NO.5 padel court is not just a playing surface, but a meticulously engineered structure built for performance, safety, and longevity, capable of withstanding the rigors of commercial or private use.

Application Cases and Client Testimonials

Our padel court solutions have been successfully deployed across a diverse range of projects globally, demonstrating their adaptability and superior performance. From major sports complexes to exclusive residential developments, the NO.5 padel court with separated roof has consistently exceeded client expectations.

- The Grand Sports Arena, Dubai, UAE: We supplied and installed 8 NO.5 padel courts, including two panoramic padel courts for tournament play, within their newly constructed multi-sport complex. The separated roof design proved invaluable in combating the intense desert heat, allowing for year-round play and significantly increasing court rental hours. "Yocoolcn's expertise was evident from design to installation. The courts are a major draw, and the roof system is a game-changer for our climate," praised Mr. Al-Maktoum, Facility Manager.

- Ocean View Residences, Sydney, Australia: A private client commissioned a bespoke NO.5 padel court for their luxury coastal property. The challenge was integrating the court while ensuring maximum durability against saline air. Our advanced galvanization and powder coating process ensured superior corrosion resistance, validated by continuous monitoring. The client commented, "The paddle court is a masterpiece. It looks stunning and shows no signs of wear, even with the harsh coastal environment. The separated roof ensures comfortable play even on the brightest days."

- Urban Recreation Center, Berlin, Germany: As part of a municipal initiative to promote active lifestyles, two NO.5 padel courts were installed. The quick installation time and robust construction were key factors. The separated roof ensured the courts remained operational during typical European rainfalls. "Our community absolutely loves the new padel tennis courts. They are always busy, and the quality is exceptional. It's truly a valuable asset for public use," stated Mayor Schmidt.

These case studies underscore our capability to deliver high-quality, customized padel court solutions that meet diverse operational and environmental demands, building a strong foundation of experience and client trust.

Professional Padel Court FAQ

Understanding the intricacies of padel court construction is vital for making informed decisions. Here are answers to some frequently asked questions:

- What are the standard dimensions for a professional padel court?

A professional padel court measures 20 meters long by 10 meters wide internally. The height of the walls varies: 3 meters at the back walls, extending 4 meters high with mesh, and 2 meters high at the side walls, extending 3 meters high with mesh.

- What type of glass is used for padel court walls, and why?

We use 12mm thick tempered safety glass (also known as toughened glass) for the walls. Tempering is a process that heats and rapidly cools the glass, making it 4-5 times stronger than regular glass. This is crucial for player safety and durability, as tempered glass, if broken, shatters into small, relatively harmless pieces, unlike sharp shards of untempered glass. It also provides excellent transparency for a panoramic padel court experience.

- How are the steel structures for a padel court protected against corrosion?

Our steel structures undergo a dual-layer anti-corrosion treatment: first, hot-dip galvanization, where steel is immersed in molten zinc, creating a metallurgical bond that provides cathodic protection and a robust barrier (min. 80 microns thick). Second, an electrostatic powder coating is applied, offering an additional layer of protection against UV, abrasion, and chemicals, ensuring extreme longevity for the padel court.

- What type of playing surface is recommended for a paddle court?

The most common and recommended playing surface for a paddle court is synthetic turf, typically made of monofilament or fibrillated fibers, with a pile height of 10-12mm. It is usually infilled with silica sand to provide optimal ball bounce, traction for players, and shock absorption. The choice between monofilament (more durable, less infill migration) and fibrillated (softer, better infill retention) depends on specific player preference and budget.

- What is the purpose of a separated roof structure on a padel court like the NO.5 model?

A separated roof structure, as featured on our NO.5 padel court, offers comprehensive weather protection (rain, direct sun, light snow) without enclosing the court. This allows for year-round play, enhances player comfort by reducing heat build-up and glare, and maximizes the return on investment for commercial facilities. It provides superior shelter compared to cantilevered or integrated roof designs, ensuring an optimal playing environment for a padel tennis court.

- What maintenance is required for a padel court?

Routine maintenance for a padel court is relatively low. It primarily involves brushing the synthetic turf to redistribute sand infill and remove debris, occasional cleaning of glass walls, and checking the tension of the mesh fencing. Periodic inspections of the steel structure for any signs of wear or loose bolts are also recommended to ensure structural integrity and player safety.

- What is the typical lead time and installation duration for a padel court?

The typical lead time for manufacturing a padel court (like the NO.5 model) can range from 4 to 8 weeks, depending on customization and current production load. On-site installation generally takes between 5 to 10 days for a single court, assuming foundation work is already completed. Larger projects involving multiple courts or complex site conditions may require more time.

Enhancing Trustworthiness: Warranty, Support, and Delivery

At Yocoolcn, we prioritize trust and long-term client relationships. Our commitment to quality extends beyond manufacturing to comprehensive support and transparent processes.

- Warranty Commitment: We offer an industry-leading warranty for our NO.5 padel court. This includes a 10-year structural warranty on all hot-dip galvanized and powder-coated steel components, a 5-year warranty on tempered glass panels against manufacturing defects, and a 2-year warranty on LED lighting systems and synthetic turf (subject to specific turf manufacturer's warranty terms). This reflects our confidence in the durability and quality of our products.

- Transparent Delivery & Installation: Upon order confirmation, clients receive a detailed project timeline, including manufacturing milestones, shipping schedules, and estimated on-site installation dates. We maintain open communication throughout the process, providing regular updates. Our logistics team ensures efficient and secure delivery worldwide. For installation, we provide comprehensive manuals and, where required, can dispatch our experienced supervisory teams or recommend certified local partners to ensure flawless assembly of your padel court.

- Dedicated Customer Support: Our relationship doesn't end after delivery. We offer dedicated after-sales support for any inquiries, maintenance guidance, or spare parts requirements. Our technical team is available remotely to assist with troubleshooting or operational advice, ensuring your padel court remains in peak condition for years to come. Client testimonials consistently highlight our responsiveness and commitment to satisfaction.

The rise of padel courts signifies a significant shift in global sports culture, demanding innovative and robust infrastructure. The NO.5 padel court with separated roof embodies this evolution, offering a premium, durable, and all-weather solution that addresses the needs of modern sports facilities and discerning private owners. Our meticulous craftsmanship, adherence to international standards, and unwavering commitment to client satisfaction ensure that every paddle court we deliver is an investment in quality and an enduring asset.

For further insights into the global padel industry and technical standards, we recommend exploring resources from reputable organizations and academic publications:

- International Padel Federation (FIP) - Official website provides rules, rankings, and industry news: https://www.padelfip.com/

- ASTM International - Standards for sports equipment and surfacing (search for relevant standards like F1936 or F1551): https://www.astm.org/

- Journal of Sports Sciences - Academic papers on sports performance and facility design (e.g., studies on surface friction or player biomechanics in padel): https://www.tandfonline.com/loi/rjss20