The global sports infrastructure landscape is witnessing a significant transformation, largely driven by the explosive growth of padel. Once primarily popular in Spain and Latin America, padel has transcended its regional confines to become one of the fastest-growing sports worldwide. This surge is fueled by its accessibility, social nature, and engaging gameplay, attracting a diverse demographic of players. As a result, the demand for high-quality padel court installations is experiencing unprecedented growth, pushing manufacturers to innovate in design, materials, and construction techniques. This evolving market requires robust, durable, and aesthetically pleasing courts that meet international standards and cater to diverse client needs, from professional clubs to private residential setups. The focus remains on delivering courts that enhance player experience while ensuring long-term operational efficiency.

This burgeoning market necessitates a deep understanding of structural integrity, material science, and regulatory compliance. The widespread adoption of padel tennis court facilities across Europe, the Middle East, and North America underscores a shift in recreational sports, making it a critical area for investment and development. Suppliers must not only understand the sport's unique requirements but also possess the manufacturing prowess to deliver courts that withstand rigorous use and varying climatic conditions. The emphasis on player safety, ball rebound consistency, and maintenance ease is paramount, driving advancements in every component of the court.

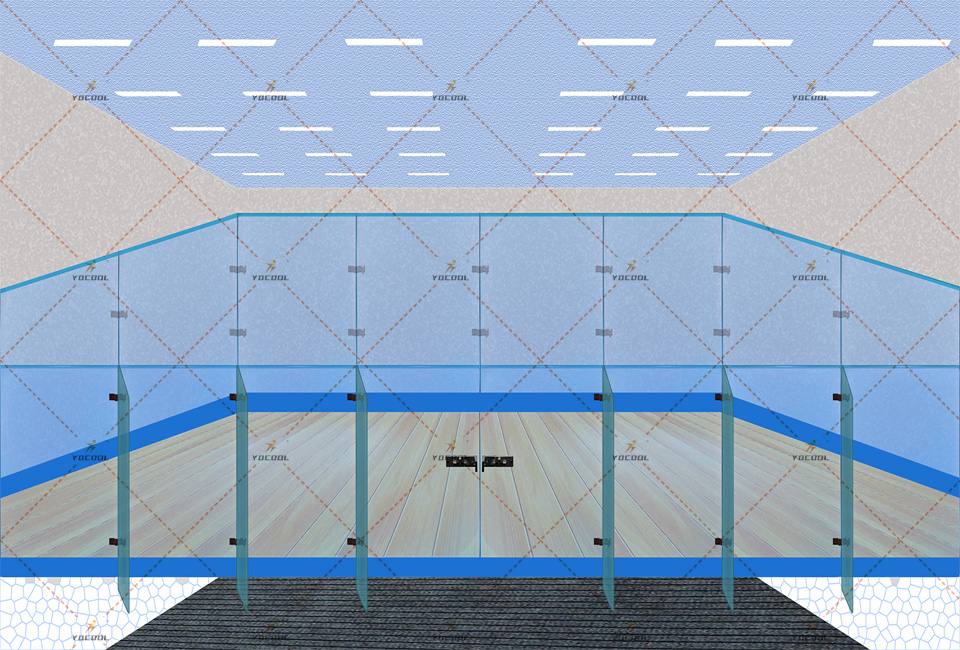

A state-of-the-art padel court is an engineering marvel, meticulously designed to provide an optimal playing environment while ensuring durability and safety. The standard dimensions for a padel court are 10 meters wide by 20 meters long, enclosed by walls typically 3 or 4 meters high. The main structural components include tempered glass panels, metal mesh, and a specially designed synthetic turf playing surface. Tempered glass, typically 10mm or 12mm thick, is crucial for spectator visibility and ball rebound consistency, offering superior resistance to impact compared to standard glass. The metal structure, often made from galvanized steel, provides the robust framework, ensuring stability and longevity, even in challenging outdoor conditions. All components must comply with stringent international standards such as UNE EN 10155 for steel and UNE EN 12150-1 for tempered glass, guaranteeing structural integrity and player safety.

Precision manufacturing of glass panels for padel court structures.

The playing surface, typically fibrillated or monofilament synthetic turf with sand infill, is engineered for optimal ball speed and player comfort, minimizing injury risks. The quality of the turf directly impacts game flow and player satisfaction. Furthermore, lighting systems, crucial for evening play, often utilize LED technology for energy efficiency and uniform illumination, adhering to sport-specific lighting standards. The rise of the panoramic padel court design has further enhanced the spectator experience, utilizing full glass back walls to offer unobstructed views, a feature that demands even greater precision in glass manufacturing and installation. These designs often feature minimalist steel frames, maximizing transparency and aesthetic appeal, suitable for high-profile locations or professional tournaments.

| Component | Material/Type | Key Specification | Standard/Benefit |

|---|---|---|---|

| Dimensions | Standard Court | 20m (L) x 10m (W) | International Padel Federation (FIP) regulated |

| Glass Walls | Tempered Safety Glass | 10mm or 12mm thickness | High impact resistance, optical clarity (UNE EN 12150-1) |

| Metal Structure | Galvanized Steel | Hot-dip galvanized, Powder Coated | Corrosion resistance, structural stability (UNE EN 10155) |

| Playing Surface | Synthetic Turf | Fibrillated or Monofilament, 12-15mm pile height | Consistent ball bounce, player comfort, low maintenance |

| Lighting | LED Floodlights | 200-300 Lux average (recreational), >500 Lux (professional) | Energy efficiency, uniform illumination |

The manufacturing of a premium padel court involves a rigorous, multi-stage process designed to ensure precision, durability, and compliance with the highest quality standards. It begins with the meticulous selection of raw materials, including high-grade steel for the structural framework and specialized float glass for the walls. The steel components undergo advanced fabrication techniques, starting with precision cutting, often utilizing CNC (Computer Numerical Control) machines to ensure exact dimensions for every beam and post. This is followed by welding processes performed by certified technicians, ensuring robust and seamless joints. Post-welding, the steel frames are typically hot-dip galvanized, providing an unparalleled layer of corrosion protection, crucial for outdoor installations. This process, adhering to standards like ISO 1461, ensures a lifespan of decades, significantly extending the court's service life and reducing maintenance requirements.

Precision fabrication of the metal frame for a padel tennis court.

For the glass panels, cutting-edge tempering processes are employed, transforming standard glass into highly durable safety glass. This involves heating the glass to extreme temperatures and then rapidly cooling it, creating compression in the outer layers and tension in the core, making it four to five times stronger than annealed glass and, importantly, causing it to shatter into small, blunt pieces upon breakage, minimizing injury risk. Each glass panel, like those used in a NO.1 All Glass Squash Court, undergoes stringent quality control, including optical distortion checks and impact resistance tests. The final surface treatment of metal elements often includes electrostatic powder coating, providing an aesthetic finish and additional protection against UV radiation and abrasion. Throughout the entire manufacturing chain, adherence to international quality management systems, such as ISO 9001, is paramount. This ensures traceability of materials, consistent production quality, and continuous improvement, culminating in a superior paddle court that meets and exceeds client expectations for safety, performance, and longevity.

The versatility and growing popularity of padel make a quality paddle court an invaluable addition to a wide range of facilities. From dedicated sports clubs and professional training centers to luxury resorts, private residential estates, and municipal sports complexes, the application scenarios are diverse. For sports clubs, adding padel courts significantly boosts membership and revenue, tapping into a new and enthusiastic player base. Resorts and hotels leverage them to enhance guest experience and amenity offerings, attracting more visitors. Private installations offer exclusive recreational opportunities, increasing property value and lifestyle appeal. The compact footprint of a padel tennis court, significantly smaller than a tennis court, allows for efficient use of space, making it an attractive option for urban environments or areas with limited land.

A newly installed padel court, ready for play.

The technical advantages of a well-engineered panoramic padel court extend beyond mere aesthetics. The tempered glass walls ensure excellent ball rebound consistency, critical for competitive play, and offer unparalleled durability against impacts from players or padel racquets. The galvanized steel structure provides superior resistance to environmental factors like rust and extreme weather, ensuring a long operational lifespan with minimal maintenance. Unlike traditional sports surfaces that may require frequent re-painting or repair, the synthetic turf used in modern padel courts is designed for high traffic and resilience, requiring only routine cleaning. These courts represent a sound long-term investment due to their low operational costs, robust construction, and high user appeal, promising strong return on investment for commercial operators and lasting enjoyment for private owners. They are engineered for performance, designed for durability, and built for widespread appeal.

Recognizing that each project presents unique challenges and requirements, leading manufacturers offer comprehensive customized solutions for padel court installations. This bespoke approach ensures that every aspect, from site preparation and foundation design to court specifications and ancillary facilities, is precisely aligned with the client's vision and local regulations. Customization options often include specific dimensions for non-standard spaces, choice of turf color and texture, bespoke lighting configurations, and branding integration on the court structure or glass panels. Advanced CAD/CAM software is utilized for precise engineering and visualization, allowing clients to review and approve designs before manufacturing commences. This consultative process, combined with extensive project management expertise, guarantees seamless execution from initial concept to final installation.

Visualizing customized padel court solutions for unique spaces.

Leading providers bring years of experience to the table, having successfully completed hundreds of paddle court projects across diverse geographies and climates. This includes expertise in managing logistics for international shipping, handling customs clearance, and coordinating with local installation teams. Client testimonials frequently highlight the seamless project delivery, exceptional product quality, and responsive after-sales support. For instance, a major sports club in Dubai recently commissioned ten panoramic courts, citing the manufacturer's proven track record in extreme heat conditions and ability to meet strict delivery timelines as key decision factors. Similarly, a residential developer in Europe chose a provider for their integrated solutions, including soundproofing and aesthetic integration with the surrounding landscape. This deep well of experience ensures that regardless of the project's scale or complexity, clients receive a high-performance paddle tennis court solution that is delivered on time and within budget, backed by robust guarantees.

We understand the importance of timely project completion. Our typical manufacturing lead time for a standard padel court is 4-6 weeks, followed by efficient global shipping. Delivery timelines will vary based on destination and project scope, with detailed schedules provided during the proposal phase. All our padel courts are backed by a robust warranty. We offer a 10-year structural warranty on the galvanized steel framework, ensuring protection against corrosion and manufacturing defects. Tempered glass panels come with a 5-year warranty against defects, and the synthetic turf typically carries an 8-year manufacturer's warranty against excessive wear and UV degradation. Our comprehensive after-sales support includes technical assistance, spare parts availability, and guidance on maintenance, ensuring your investment in a paddle court remains protected and performs optimally for years to come. We are committed to transparency and provide all necessary documentation and certifications, including ISO and ANSI compliance, for every project.

This is the last article

Panoramic Padel Courts | Build Your Dream Paddle Tennis Court

Premium Padel Courts & Panoramic Designs

Premium Paddle Racquet | Enhance Your Padel Court Performance

Premium Padel Courts: Design Your Perfect Padel Tennis & Panoramic Court

Premium Padel Court & Panoramic Padel Tennis Courts

Elite Paddle Racquets: Power, Control & Comfort for Padel Tennis