| Model | Shape | Weight (g) | Material | Core | Surface Finish | Balance |

|---|---|---|---|---|---|---|

| Elite Pro | Teardrop | 365–375 | Carbon Fiber | EVA Soft Black | Rough 3D | Mid |

| Control 3K | Round | 355–365 | 3K Carbon + Fiberglass | EVA Medium | Smooth | Low |

| NO.6 Court Edition | Diamond | 370–385 | Full Carbon 18K | EVA Pro Density | Sand Touch | High |

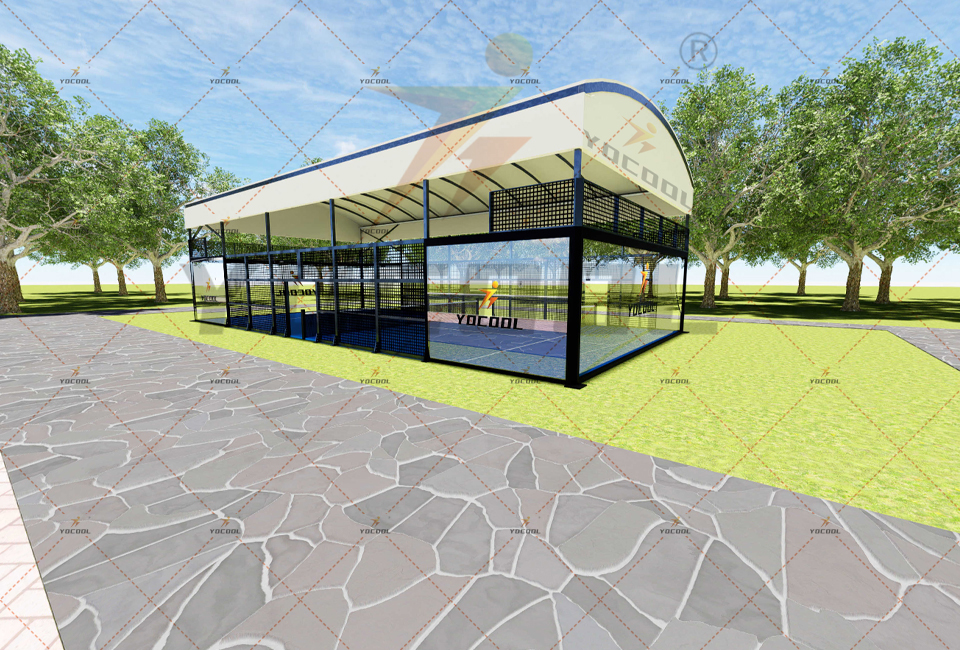

| Parameter | NO.6 Padel Court with Conjoined Roof |

Industry Standard |

|---|---|---|

| Frame Material | Hot-dip Galvanized Q235B Steel (ISO 1461) | Q235 Steel |

| Glass | 12mm Tempered Glass (EN12150) | 10mm Tempered Glass |

| Roof Type | Integrated Steel Sandwich Panel (0.7mm pre-coated) | Freestanding Metal/None |

| Surface | TiO₂-embedded Artificial Turf (Water-permeable, UV50+) |

Standard Nylon Turf |

| Wind Load Resistance | ≥ 130km/h | ≤ 90km/h |

| Corrosion Resistance | Salt Spray > 1000h (ISO 9227) | Salt Spray ~ 360h |

| Service Life | >15 Years | ~10 Years |

| Certification | ISO 9001, SGS Certified | ISO 9001 / - |

| Criteria | NO.6 Padel Court with Conjoined Roof |

Leading European Brand | Generic Brand (Asia) |

|---|---|---|---|

| Roof Integration | Full Conjoined (ISO tested) | Modular/Freestanding | None/Optional |

| Frame Steel Type | Hot Dip Q235B (≥3.5mm) |

Q235 (2.8mm) | Q235 (2.5mm) |

| Glass Thickness | 12mm | 10mm | 8/10mm |

| Surface Turf | TiO₂ Artificial (UV50+) | Nylon/PE | Nylon |

| Salt Spray Test | >1000h | 500h | 200h |

| Guarantee | 5 Years | 2–3 Years | 1 Year |

| Certifications | ISO 9001, EN12150, TUV, SGS | ISO 9001, EN12150 | ISO 9001 |

This is the last article

AI-Designed Paddle Racquet | GPT-4 Turbo Tech

Premium Paddle Racquet | AI-Optimized Design

Smart Padel Courts with GPT-4 Turbo AI

AI-Powered Paddle Racquet w/ GPT-4-Turbo Optimized

China Pro Ping Pong Paddle | Premium Spin Control

Premium AI-Enhanced Padel Court | GPT-4 Turbo Design