(industrial flooring)

Industrial flooring plays a pivotal role in the safety, efficiency, and durability of spaces across sectors as diverse as manufacturing, warehousing, pharmaceutical facilities, and sports complexes. Over the past decades, industrial flooring

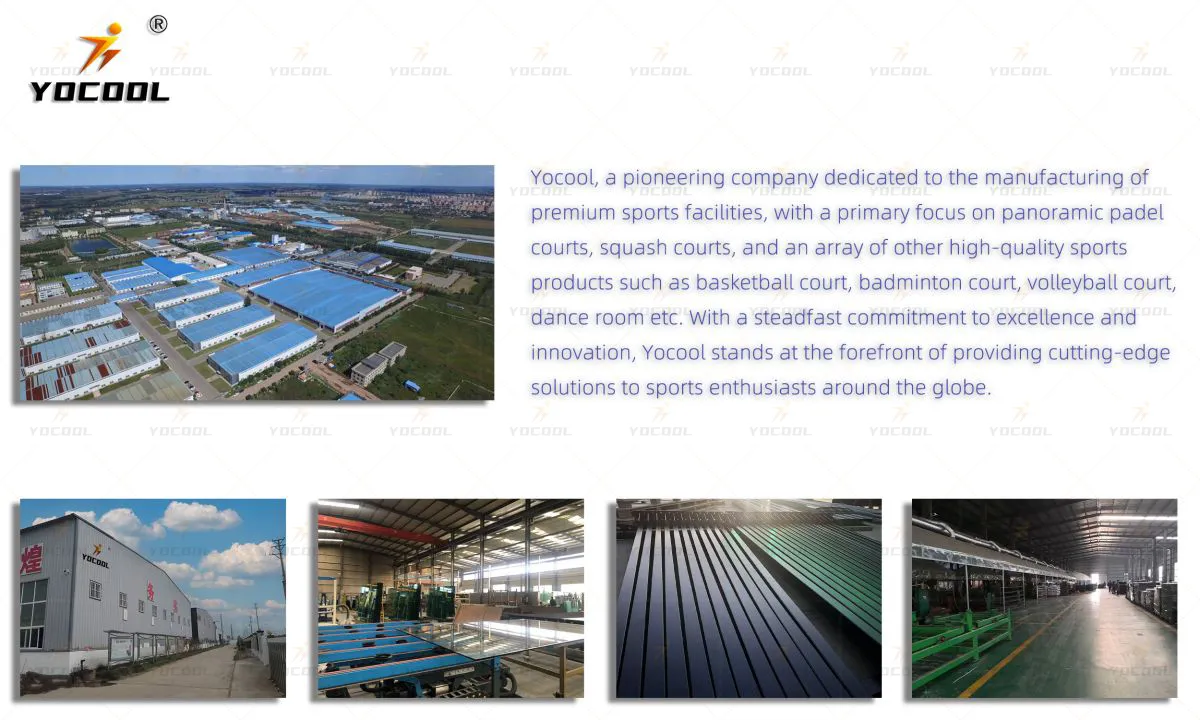

solutions have evolved dramatically, reflecting advances in material science and the growing need for bespoke manufacturing environments. As a result, more businesses are leveraging state-of-the-art flooring to drive productivity, meet regulatory standards, and enhance the longevity of their facilities. Attention to innovative trends—such as panoramic padel tennis court manufacturer practices—has begun to influence expectations even outside traditional industrial settings, broadening the functional and aesthetic scope of industrial flooring systems.

According to a 2023 Markets and Markets report, the global industrial flooring market is valued at approximately USD 8.7 billion and is projected to reach USD 12.3 billion by 2028, growing at a CAGR of 6.9%. Factors fueling this expansion include the surge in industrial automation, increasing demand for chemical-resistant flooring, and the expansion of logistics and warehousing infrastructure. The Asia-Pacific region commands the largest market share at 41%, propelled by rapid industrialization in China, India, and Southeast Asia. In addition, construction of specialized facilities—such as panoramic padel tennis courts—has created unique demand spikes, with sports flooring solutions expected to rise by 5% annually through 2027.

Data reveals that nearly 68% of end-users consider durability the top criterion when selecting industrial flooring materials, while 54% also prioritize ease of maintenance. Acrylic, epoxy, and polyurethane coatings dominate the industrial sector due to their resilience against abrasion, chemical spills, and heavy load impacts. Recent innovation has also introduced hybrid composite systems with lifecycle costs, on average, 17% below traditional concrete alternatives. This shift underscores the value placed on total cost of ownership (TCO), reflecting a strategic focus on sustainability and operational efficiency.

The continuous innovation of industrial flooring technologies has redefined performance benchmarks for strength, hygiene, and adaptability. Today’s most advanced solutions use multi-layer reinforcement, nano-sealants, and antimicrobial additives, providing industry-leading abrasion resistance and supporting cleanroom-standard environments. For panoramic padel tennis court manufacturer needs, system flexibility is key—combining glass wall integration, UV-resistant coatings, and specialized sports-traction layers.

Smart flooring, incorporating IoT-enabled sensors for real-time load, moisture, and temperature monitoring, delivers new possibilities for predictive maintenance and asset protection. For industrial sectors handling hazardous chemicals, inert, non-porous, and high-density overlays minimize contamination risks—documented in a 2022 study by the International Flooring Federation to improve annual productivity by up to 14%. These technical breakthroughs create a multifaceted value proposition, uniting immediate operational gains with long-term reliability.

Selecting an industrial flooring provider involves careful analysis of technical capabilities, regional presence, customization bandwidth, and after-sales service. The following table presents a side-by-side comparison of four prominent manufacturers active in both industrial flooring and panoramic padel tennis court sectors:

| Manufacturer | System Lifespan (Years) | Customization Options | Average Installation Time (Days) | Global Project Portfolio | After-sales Service (1-5) |

|---|---|---|---|---|---|

| FloorTech International | 25+ | Extensive (Color, Finish, Load Rating) | 5-10 | 48 Countries | 5 |

| Duracon Systems | 20 | Limited (Predefined Sets) | 7-14 | 30 Countries | 4 |

| Elite Sports Surfaces | 18-22 | Full (Custom Graphics, Sport-specific) | 10-21 | 33 Countries | 5 |

| PadelPro Manufacturing | 15 | Medium (Material & Color Variant) | 7-14 | 22 Countries | 3 |

The data demonstrate that leading vendors distinguish themselves through longer warranties, a broader global footprint, and superior post-installation engagement. Manufacturers embracing high levels of customization—such as FloorTech International and Elite Sports Surfaces—cater effectively to bespoke architectural and operational needs, a vital factor in both industrial and recreational flooring segments.

Achieving peak performance from industrial flooring requires tailored solutions rather than one-size-fits-all products. Today, customization covers everything from thermal cycling tolerance and static dissipation to anti-slip grading and even branding integration. A leading panoramic padel tennis court manufacturer aligns flooring specifications with court playability, weather conditions, and aesthetic aspirations, ensuring compliance with international sports federations and localized construction codes.

Collaborative design processes now routinely involve 3D simulation of live loads, proactive environmental impact assessments, and client-focused mockups. For heavy manufacturing zones, reinforced underlays and slip-resistant topcoats are tailored to handle up to 15,000 kg axle ratings. Facility managers in pharmaceutical and technology sectors request particle-shedding analyses and seamless transitions to wall and drainage interfaces, highlighting the rising need for holistic systems engineering in industrial flooring deployment.

The adaptability of industrial flooring is exemplified in diverse, high-stakes environments. In 2023, an electronics manufacturer in Germany overhauled its factory floor with an antimicrobial epoxy-urethane system, reducing surface maintenance labor by 30% and extending scheduled full shutdown intervals by six months. Similarly, a major logistics provider in Singapore equipped its 72,000 m2 warehouse with fiber-reinforced hybrid flooring capable of withstanding 24/7 automated forklift activity without surface degradation.

Panoramic padel tennis court manufacturer projects showcase the fusion of industrial durability and sporting elegance. For instance, a flagship sports complex in Madrid installed UV-stabilized acrylic flooring with integral glass panels, exceeding playability and safety standards while reducing annual surface re-coating budgets by €18,000. Across emerging markets, schools and recreational centers are adopting similar solutions, often reporting increases in user satisfaction and revenue linked to the modernized play experience. These examples illustrate how industrial flooring and state-of-the-art court design can jointly advance operational goals, safety, and user engagement.

Industrial flooring’s relevance reaches far beyond mere functionality, shaping environments that support productivity, resilience, and operational excellence. With continual advances in materials science, customization, and digital monitoring, modern solutions set new standards in both traditional factories and specialized venues such as panoramic padel tennis courts. Market data, comparative manufacturer performance, and authentic application stories collectively reveal a sector defined by innovation, technical rigor, and customer-centricity. As enterprises worldwide prioritize smart infrastructure investment, industrial flooring will remain a cornerstone for progress, safety, and competitive distinction in the built environment.

(industrial flooring)

High-Performance Sports Floor Solutions PVC Sports Floor & Rubber Floor Supplier

Premium Industrial Flooring Solutions Leading Panoramic Padel Tennis Court Manufacturer

Homogeneous Transparent Floor Durable & Stylish Rubber Floor Solutions

Premium Rubber Composite Floor for Ultimate Durability & Safety Rubber Floor Mat Solutions

High-Quality Industrial Flooring Solutions for Factories Expert Installation & Cost Saving

Premium Rubber Brick Flooring Durable & Slip-Resistant