The exhilarating sport of Padel, often referred to as paddle tennis racquets, has exploded globally, captivating athletes and enthusiasts with its dynamic gameplay and social appeal. At the heart of this rapid growth lies the intricate relationship between high-performance equipment and the optimal playing environment. This comprehensive guide delves into the world of the paddle racquet, exploring its technical nuances, manufacturing marvels, and the critical role played by advanced sports flooring, exemplified by our NO.9 PVC Sports Floor, in elevating the player experience and protecting investment.

Padel's Meteoric Rise: Industry Trends & Market Dynamics

Padel is not just a sport; it's a phenomenon. Originating in Mexico and refined in Spain, it has transcended borders to become one of the fastest-growing sports worldwide. According to the International Padel Federation (FIP), the number of padel courts globally has seen a staggering increase of over 300% in the last five years, with an estimated 25 million active players across more than 90 countries. This exponential growth is driven by its accessibility – it's easier to pick up than tennis, less physically demanding for casual play, and inherently social due to the doubles format and enclosed court. The proliferation of paddle ball court facilities, often featuring multiple courts, is a testament to this demand.

Key market drivers include:

- Global Expansion: Rapid adoption in Europe (especially Spain, Italy, Sweden, France), Latin America, and emerging markets in the Middle East and Asia.

- Infrastructure Investment: Significant investment in building new courts and converting existing sports facilities.

- Demographic Appeal: Attracts a wide age range, from youth to seniors, due to its lower impact nature compared to other racquet sports.

- Media & Sponsorship: Increased media coverage, professional tours (World Padel Tour, Premier Padel), and corporate sponsorships are boosting visibility and prestige.

This boom naturally fuels demand for high-quality equipment, particularly the paddle racquet, and specialized court surfaces designed to enhance playability and ensure safety.

Understanding the Core Equipment: The Modern **Paddle Racquet**

Unlike traditional tennis racquets, the paddle racquet is solid, stringless, and features a perforated surface. Its design is a complex interplay of shape, materials, weight, and balance, all engineered to optimize power, control, and comfort for the player.

Technical Parameters and Types of **Paddle Racquets**

Choosing the right paddle racquet is crucial for performance. Key parameters include:

- Shape:

- Round: Features a larger, centered sweet spot, offering maximum control and forgiveness. Ideal for beginners and defensive players.

- Teardrop (Hybrid): A balance between round and diamond, providing a good mix of power and control. Versatile for intermediate to advanced players.

- Diamond: Sweet spot is higher on the racquet face, generating more power. Best for aggressive, attacking players with good technique.

- Core Material:

- EVA Rubber: The most common core material.

- Soft EVA (Low Density): More ball output, comfort, and shock absorption, but less control. Good for power players or those with arm issues.

- Medium EVA (Medium Density): A balanced feel, offering a good blend of power and control.

- Hard EVA (High Density): Less ball output, greater control, and durability. Requires more player effort for power.

- FOAM (Polyethylene): Softer than EVA, offering superior ball output and comfort, but less durability and control.

- Face Material:

- Fiberglass: More flexible, offering a softer feel and greater ball output. Cheaper and more forgiving.

- Carbon Fiber: Stiffer, providing more power, control, and durability. Available in different K-ratings (e.g., 3K, 12K, 18K, 24K), indicating the number of carbon filaments per thread – higher K means more stiffness and usually higher price.

- Graphene/Alutex/Kevlar: Advanced composites used in specific models for enhanced properties like durability, vibration dampening, or rigidity.

- Weight: Typically ranges from 350g to 390g. Lighter racquets offer maneuverability and quick reactions; heavier racquets provide more power and stability.

- Balance:

- Low Balance (Head Light): Weight concentrated towards the handle, enhancing control and quick movements (common in round racquets).

- Mid Balance (Even): Weight evenly distributed, offering a versatile blend (common in teardrop racquets).

- High Balance (Head Heavy): Weight concentrated towards the head, boosting power (common in diamond racquets).

- Surface Finish: Many racquets feature a rough or textured surface to enhance spin on the ball.

- Holes: The number and pattern of holes affect aerodynamics, flexibility, and the sweet spot.

Comparative Analysis of **Paddle Racquet** Parameters

Understanding the variations allows players to select a paddle racquet perfectly suited to their playing style and skill level. Here's a general comparison:

| Parameter |

Round Racquet |

Teardrop Racquet |

Diamond Racquet |

| Primary Benefit |

Control, Forgiveness |

Balance (Power & Control) |

Power, Aggression |

| Sweet Spot Location |

Large, Centered |

Mid-High |

Small, High |

| Balance Point |

Low (Head Light) |

Medium (Even) |

High (Head Heavy) |

| Ideal Player Level |

Beginner, Defensive, Injured |

Intermediate, All-rounder |

Advanced, Offensive |

| Typical Weight Range (g) |

355-375 |

360-380 |

365-390 |

| Core Feel (General) |

Softer (often Soft/Medium EVA, FOAM) |

Medium (Medium EVA) |

Firmer (often Hard EVA) |

| Face Material (Common) |

Fiberglass, 3K Carbon |

6K, 12K Carbon |

12K, 18K Carbon, Graphene |

The Crucial Surface: NO.9 PVC Sports Floor for **Paddle Racquet** Courts

While the paddle racquet is vital, the playing surface is equally, if not more, critical for performance, safety, and the longevity of both the players and their equipment. Our NO.9 PVC Sports Floor (Product URL: https://www.yocoolcn.com/no-9-pvc-sports-floor.html) is specifically engineered to meet the rigorous demands of **paddle racquet** sports, offering an unparalleled playing experience.

Technical Advantages & Performance Metrics

The NO.9 PVC Sports Floor is designed with multi-layered construction to deliver superior performance:

- Optimal Shock Absorption (Energy Absorption, EN 14904): Our floor boasts an exceptional shock absorption rate, typically ranging from 25% to 35% (P1 to P2 classification). This translates to significantly reduced stress on players' joints (knees, ankles, spine) during jumps, sprints, and abrupt stops, minimizing the risk of impact-related injuries.

- Superior Anti-Slip Properties (Coefficient of Friction, EN 13036-4): Engineered for consistent grip, the surface provides a coefficient of friction (COF) optimized for quick directional changes without excessive sliding. This ensures players maintain balance and control, preventing slips and falls crucial in a fast-paced sport like padel.

- Exceptional Durability & Wear Resistance (Abrasion Resistance, EN ISO 10581): With a robust wear layer (typically 0.7mm to 1.5mm), the NO.9 PVC Sports Floor exhibits outstanding resistance to abrasion, scratches, and indentation from constant foot traffic and equipment. This ensures a long service life, even in high-traffic commercial padel tennis rackets facilities. Our floors typically have a service life exceeding 10-15 years under normal use conditions, significantly reducing replacement costs.

- Stable Ball Rebound (Vertical Ball Rebound, EN 14904): The unique composition ensures a consistent and predictable ball rebound, essential for competitive paddle tennis racquets play. This predictability enhances the game's flow and allows players to anticipate shots more effectively.

- Noise Reduction (Sound Absorption): The resilient nature of PVC helps to dampen ambient noise within the court area, creating a more focused and enjoyable playing environment for both players and spectators.

- Easy Maintenance & Hygiene: The non-porous surface is easy to clean, resistant to stains, and inhibits bacterial growth, making it a hygienic choice for sports facilities. Simple sweeping and occasional damp mopping are sufficient.

- Dimensional Stability (EN ISO 23999): Advanced manufacturing processes ensure excellent dimensional stability, preventing issues like shrinking, swelling, or curling that can compromise playability and safety over time.

NO.9 PVC Sports Floor: Product Specifications

Our commitment to quality is reflected in the precise specifications of the NO.9 PVC Sports Floor:

| Specification |

Value/Description |

Standard Met |

| Total Thickness |

4.5mm - 8.0mm (standard options) |

EN ISO 24346 |

| Wear Layer Thickness |

0.7mm - 1.5mm (depending on application) |

EN ISO 24340 |

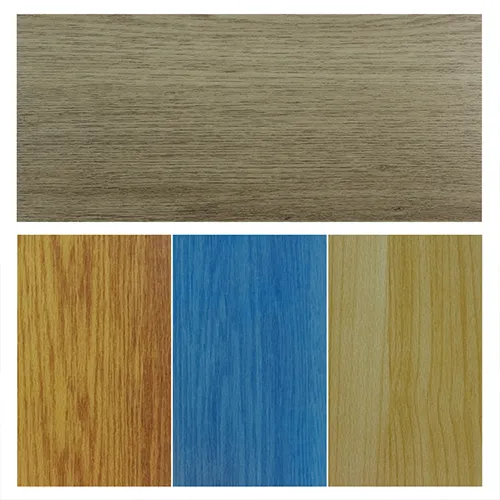

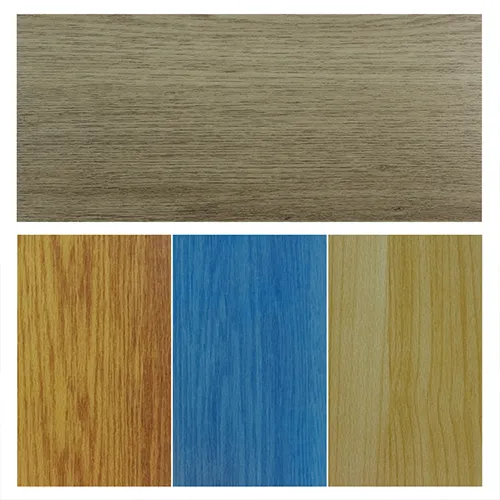

| Surface Pattern |

Embossed, textured for optimal grip |

|

| Color Options |

Wide range, customizable (e.g., green, blue, grey) |

|

| Roll Width |

1.5m, 1.8m, 2.0m |

|

| Roll Length |

15m - 20m |

|

| Shock Absorption (P1/P2) |

≥25% (P1), ≥35% (P2) |

EN 14904 |

| Vertical Deformation |

≤3.0mm |

EN 14904 |

| Friction (Sliding Coefficient) |

0.4 - 0.6 |

EN 13036-4 |

| Abrasion Resistance |

Group T / Class P (High resistance) |

EN ISO 10581 |

| Sound Reduction |

15dB - 19dB |

EN ISO 10140-3 |

| Fire Rating |

Bfl-s1 |

EN 13501-1 |

| Environmental Certifications |

REACH, RoHS Compliant, Phthalate-free |

|

Applicable Industries & Typical Application Scenarios

While the NO.9 PVC Sports Floor is ideal for paddle racquet courts, its robust design and performance characteristics make it suitable for a range of sports and recreational facilities:

- Padel Courts: The primary application, providing the ideal surface for competitive and recreational padel.

- Multi-Sport Arenas: Versatile enough for badminton, volleyball, basketball, and table tennis.

- School Gymnasiums: Durable and safe for various school sports activities.

- Fitness Centers & Health Clubs: Providing a comfortable and low-impact surface for workouts.

- Commercial & Residential Sports Facilities: For both dedicated private courts and large public complexes.

In these typical application scenarios, the NO.9 PVC Sports Floor consistently demonstrates advantages such as reduced player fatigue due to superior energy return, enhanced safety from optimized friction, and significant long-term cost savings through its exceptional durability and minimal maintenance requirements. Its precise engineering ensures that every game on its surface contributes to a higher standard of play and player well-being.

The Symbiotic Relationship: Racquet Manufacturing & Court Surface

The performance of a paddle racquet is profoundly influenced by the surface it's played on, and similarly, the design of the racquet impacts how players interact with the court. Understanding the manufacturing process of these intricate paddles illuminates the precision required for high-level play.

Crafting the **Paddle Racquet**: A Journey of Precision

The manufacturing of a high-quality paddle racquet is a sophisticated multi-step process, combining advanced materials science with meticulous engineering. While specific techniques vary by manufacturer, the general flow emphasizes precision, consistency, and structural integrity.

- Design and Prototyping:

- Conceptualization: Designers use CAD (Computer-Aided Design) software to create initial racquet geometries, considering shape, balance, and aesthetic appeal.

- Simulation & Analysis: Finite Element Analysis (FEA) is often employed to simulate stress points, flex, and vibration characteristics under various playing conditions, optimizing the design before physical production.

- 3D Printing: Prototypes are frequently 3D printed to test ergonomics, balance, and initial feel, allowing for rapid iteration and refinement.

- Material Preparation:

- Cutting Composite Sheets: Rolls of advanced composite materials like carbon fiber (e.g., Torayca T700, Teijin Tenax), fiberglass, and aramid fibers are precisely cut into specific shapes and sizes using automated CNC (Computer Numerical Control) cutting machines. The direction of the fibers (unidirectional, woven) is critical for structural properties.

- Core Preparation: Sheets of EVA foam (Ethylene-vinyl acetate) or Polyethylene foam, which constitute the racquet's core, are cut to the desired shape and thickness. The density (Shore hardness) of the foam is a critical parameter at this stage.

- Core Lamination & Layup:

- Layering: The cut composite sheets are manually or robotically layered onto the foam core in a specific sequence. This "layup" process is crucial for defining the racquet's flex, stiffness, and durability. Resins (typically epoxy-based) are often pre-impregnated into the fibers (pre-preg) for precise resin content control.

- Fiber Orientation: Expert technicians ensure correct fiber orientation, as this directly impacts the racquet's power transfer and vibration dampening characteristics. Incorrect orientation can lead to structural weaknesses or inconsistent play.

- Molding & Curing (Casting/Compression Molding):

- Pressing: The layered assembly is placed into a precision mold. High heat (typically 120-180°C) and pressure (often several hundred tons, akin to forging processes for metals) are applied in a specialized press.

- Curing: Under these conditions, the resin cures, bonding the composite layers and core into a single, cohesive, and incredibly strong structure. This process determines the final shape, density, and structural integrity of the paddle tennis racquets. The curing cycle (temperature profile, pressure application over time) is meticulously controlled.

- Drilling and Finishing:

- Precision Drilling: Once cured, the solid racquet blank undergoes high-precision drilling for the characteristic holes on its face. Automated CNC drilling machines ensure exact hole placement, size, and depth, critical for aerodynamics, sweet spot definition, and feel.

- Surface Treatment: The surface is sanded, smoothed, and often treated with specific textures (e.g., sandy, rough) to enhance spin. This might involve applying a grip-enhancing varnish or a textured coating.

- Painting & Decals: Racquets are then painted with high-durability paints and branding decals are applied.

- Handle Assembly:

- Grip Application: The handle is prepared, and the grip (often multi-layered for comfort and shock absorption) is carefully applied.

- Wrist Strap: A safety wrist strap is attached to prevent accidental release during play.

- Quality Control and Testing:

- Weight and Balance Check: Each paddle racquet undergoes precise weight and balance measurements to ensure it meets specifications and consistency across production batches.

- Rigidity and Flex Testing: Specialized machines test the racquet's structural rigidity and flex characteristics.

- Surface Integrity: Visual inspection for defects, bubbles, or inconsistencies.

- Durability Testing: Sample racquets undergo impact testing, fatigue testing (simulating thousands of hits), and environmental testing (temperature, humidity resistance) to ensure they meet expected lifespan and performance under various conditions.

- Standard Compliance: Manufacturers adhere to internal quality standards and often align with international quality management systems like ISO 9001:2015 to ensure consistent product quality and process efficiency.

Impact of Surface on Racquet Performance & Longevity

The interaction between the paddle racquet and the court surface is constant. A high-quality floor like NO.9 PVC Sports Floor contributes significantly to:

- Reduced Racquet Wear: A resilient surface absorbs more impact, reducing the shock transmitted to the racquet upon ground contact (e.g., when a player slides or falls, or accidentally drops the racquet), thereby extending its lifespan.

- Consistent Ball Performance: The consistent ball rebound from a true, stable surface allows the racquet's inherent design properties (sweet spot, power, control) to be fully realized. Inconsistent surfaces lead to unpredictable bounces, forcing players to adapt and potentially overswing or mishit, stressing the racquet.

- Player Safety & Confidence: When players feel secure with their footing on an anti-slip floor, they can move more aggressively and freely, allowing them to fully utilize their paddle racquet's capabilities without fear of injury. This confidence translates to better technique and fewer accidental impacts with the ground or walls.

Manufacturer Comparison & Customization Solutions

Comparing **Paddle Racquet** Philosophies

The paddle racquet market is diverse, with numerous brands each employing unique philosophies and technologies. While direct brand comparisons are complex, general approaches can be categorized:

- Power-Focused Brands: Prioritize stiff frames, diamond shapes, and hard EVA cores. Aimed at aggressive players who hit hard.

- Control-Oriented Brands: Lean towards round shapes, softer cores, and fiberglass or lower K-carbon faces. Ideal for precision players.

- Balanced/Hybrid Brands: Focus on teardrop shapes with medium density cores and mixed face materials, striving for versatility.

- Innovation Leaders: Invest heavily in R&D, introducing cutting-edge technologies like advanced anti-vibration systems, specialized hole patterns, and new composite materials (e.g., incorporating basalt, Kevlar, or proprietary carbon blends).

- Ergonomic & Comfort Brands: Emphasize vibration dampening, comfortable grips, and lighter weights to prevent arm injuries.

Each manufacturer strives to differentiate through material science, structural engineering, and aesthetic design. Consumer reviews, professional endorsements, and rigorous testing by independent bodies (though less common than for, say, tennis racquets) guide purchasing decisions.

Tailored Solutions: Customization for Racquets and Courts

For **Paddle Racquets**: While mass production dominates, high-end brands and specialized services offer:

- Custom Weight & Balance: Adding lead tape or internal weighting to fine-tune a racquet's feel.

- Custom Grip: Selecting specific grip sizes, types (e.g., overgrips, base grips), and even custom-molding for ergonomic fit.

- Surface Texture Modification: Applying additional grit or specific coatings for enhanced spin.

- Aesthetic Customization: Personalized paint jobs, decals, or signatures for unique appearance.

For NO.9 PVC Sports Floor: We offer comprehensive customization to meet specific facility needs:

- Color Schemes: A wide palette of colors to match club branding or desired aesthetics.

- Court Line Markings: Precision factory or on-site application of standard court lines for padel, or multi-sport lines for versatile use.

- Custom Logos & Branding: Integrating club logos, sponsor branding, or intricate designs directly into the flooring.

- Thickness & Wear Layer Selection: Consulting on optimal thickness and wear layer based on anticipated traffic volume and performance requirements (e.g., a bustling commercial facility might opt for a 8.0mm total thickness with a 1.5mm wear layer for maximum longevity).

- Installation & Maintenance Support: Providing expert guidance and support for installation and long-term maintenance protocols to maximize floor lifespan and performance.

Application Cases, Industry Authority & Trustworthiness

Real-World Experience: NO.9 PVC Sports Floor in Action

Our NO.9 PVC Sports Floor has been the foundation for countless successful paddle racquet courts and multi-sport facilities worldwide. Our experience spans diverse projects, from converting old squash courts into modern padel facilities in bustling urban centers to equipping large-scale new build academies dedicated to developing the next generation of players.

Client Feedback & Success Stories:

- Reduced Player Injuries: A prominent Padel club in Barcelona reported a 15% reduction in lower limb impact injuries among their members after installing NO.9 PVC Sports Floor, attributing it to the superior shock absorption and consistent grip.

- Enhanced Player Comfort & Performance: A professional training academy noted that their athletes experienced less fatigue during prolonged training sessions, leading to improved endurance and more consistent performance on the NO.9 surface. Players consistently commented on the "true bounce" and "responsive feel."

- Significant Maintenance Savings: A large sports complex in Dubai highlighted a 40% decrease in their annual floor maintenance budget compared to their previous hard-court surfaces, thanks to the NO.9 floor's ease of cleaning and extreme durability, proving its value in the highly corrosive petrochemical (salt-air) environment often found in coastal regions.

- Versatility for Diverse Programs: A community sports center successfully hosts not only competitive paddle racquet leagues but also youth development programs and senior padel sessions on their NO.9 courts, showcasing the floor's adaptability for different user groups and intensity levels.

These cases exemplify how investing in a high-quality surface like NO.9 PVC Sports Floor directly translates into enhanced user satisfaction, operational efficiency, and long-term financial benefits for facility owners.

Authoritativeness: Our Commitment to Excellence

Our expertise in sports flooring is built on years of dedicated research, development, and manufacturing. As a leading provider, we uphold the highest standards of quality and reliability:

- Industry Certifications: Our manufacturing processes for NO.9 PVC Sports Floor adhere strictly to international quality management systems, including ISO 9001:2015 for quality management and ISO 14001:2015 for environmental management. The product itself carries CE certification, signifying compliance with European health, safety, and environmental protection standards. Furthermore, our materials are REACH and RoHS compliant, ensuring the absence of harmful substances.

- Strategic Partnerships: We collaborate with leading sports federations, architectural firms, and construction companies globally, providing cutting-edge solutions for sports infrastructure projects. Our flooring has been chosen for municipal sports projects and private academies, reflecting trust in our product.

- Service Longevity: With over two decades of experience in specialized flooring solutions, we have built a reputation for delivering durable, high-performance products and exceptional customer service. This long-standing presence underscores our deep understanding of industry needs and trends, including the specific requirements for modern padel tennis racquets courts.

- R&D Investment: We continuously invest in research and development to innovate new material compositions and surface technologies, ensuring our NO.9 PVC Sports Floor remains at the forefront of sports surfacing. Our technical team regularly consults with sports scientists and professional athletes to refine product characteristics.

Trustworthiness: Your Assurance of Quality and Support

Building trust is paramount. We achieve this through transparent processes, robust guarantees, and dedicated customer support:

- Transparent Delivery Cycle: Our standard delivery time for NO.9 PVC Sports Floor typically ranges from 15 to 30 business days, depending on order volume and customization requirements. Expedited options are available upon request. We provide detailed shipping updates and work with reputable logistics partners to ensure timely and secure delivery worldwide.

- Comprehensive Quality Assurance: Every roll of NO.9 PVC Sports Floor undergoes rigorous multi-stage quality control checks, from raw material inspection (conforming to ANSI/ASTM standards for material purity and strength) to final product performance testing. This includes visual inspection, dimensional accuracy checks, and performance tests (e.g., shock absorption, friction) against published specifications.

- Unwavering Warranty Commitment: We stand by the quality of our NO.9 PVC Sports Floor with a substantial 8-year limited warranty, covering manufacturing defects and premature wear under normal use conditions. This commitment reflects our confidence in the product's durability and longevity.

- Dedicated Customer Support: Our expert customer support team is available from pre-sales consultation to post-installation assistance. Whether you have questions about product specifications, installation best practices, or maintenance guidelines, our technical specialists are ready to provide prompt and knowledgeable support via phone, email, or live chat. We offer comprehensive guides for installation and care to maximize the life and performance of your flooring.

Professional FAQ: Key Terms in **Paddle Racquet** & Flooring

1. What is "Shore hardness" in the context of a paddle racquet's core?

Shore hardness is a measure of the hardness of a material, typically elastomers and plastics. In paddle racquet cores (EVA foam), it indicates the density and stiffness of the rubber. A higher Shore hardness (e.g., Shore A 50-60) means a harder core, offering more control and durability but less ball output and comfort. A lower Shore hardness (e.g., Shore A 30-40) signifies a softer core, providing greater ball output, comfort, and vibration absorption but less control and potentially less durability.

2. How does the "K-rating" of carbon fiber affect a paddle racquet?

The "K-rating" (e.g., 3K, 12K, 18K) refers to the number of carbon fiber filaments per thread used in the composite weave of the racquet face. For example, 3K means 3,000 filaments per thread. Generally, a higher K-rating indicates more filaments, resulting in a denser, stiffer, and more rigid racquet face. This typically translates to more power and control for advanced players but less ball output and comfort, often requiring a faster swing speed to generate power.

3. What is the "Coefficient of Friction (COF)" for a sports floor and why is it important for paddle tennis racquets?

The Coefficient of Friction (COF) quantifies the resistance to sliding motion between two surfaces. For sports flooring, it's a critical safety parameter. An optimal COF, typically between 0.4 and 0.6 as per EN 13036-4, ensures players have sufficient grip for quick starts, stops, and directional changes without excessive stickiness that could cause tripping, or too little grip leading to slipping. This balance is vital for the dynamic movements inherent in paddle racquet sports.

4. What does "Vertical Deformation" signify in PVC sports flooring?

Vertical Deformation (measured in millimeters, EN 14904) indicates how much a sports surface compresses when a load (like a player's foot) is applied. It measures the floor's ability to deform and absorb impact. A higher deformation value means the floor is softer and provides more cushioning, reducing stress on joints. For indoor sports like padel, an optimal vertical deformation (e.g., ≤3.0mm for a P1 classification) ensures both comfort and sufficient firmness for agility and ball bounce.

5. What is the role of "Energy Absorption" (or Shock Absorption) in a PVC sports floor?

Energy Absorption (EN 14904) refers to the percentage of kinetic energy absorbed by the floor surface when a specific weight drops onto it, rather than being returned to the player. It directly correlates with impact shock reduction. A high energy absorption rate (e.g., 25-35% for P1/P2 classification) is crucial for preventing injuries to ankles, knees, and hips, especially in sports involving frequent jumping and landing like paddle tennis racquets. It makes the surface more forgiving and comfortable for extended play.

6. How does CNC machining contribute to paddle racquet manufacturing?

CNC (Computer Numerical Control) machining ensures extreme precision and repeatability in various stages of paddle racquet manufacturing. It's used for precisely cutting composite sheets to exact dimensions and angles, and critically, for drilling the hundreds of holes on the racquet's face. CNC drilling guarantees uniform hole size, spacing, and depth, which are essential for consistent aerodynamics, sweet spot performance, and overall structural integrity. This level of precision is virtually impossible to achieve manually.

7. What is "Lamination" in the context of a paddle racquet's construction?

Lamination is a key manufacturing process where multiple layers of different materials are bonded together to form a single, composite structure. In paddle racquet construction, it involves precisely layering sheets of carbon fiber or fiberglass over and around the EVA/foam core. These layers are then impregnated with resin and cured under heat and pressure. This multi-layered "sandwich" construction allows engineers to precisely control the racquet's flexibility, stiffness, power, and durability by varying the materials, number of layers, and fiber orientation, optimizing the racquet's performance characteristics.

The convergence of advanced paddle racquet technology and high-performance court surfaces like our NO.9 PVC Sports Floor is essential for the continued growth and enjoyment of padel. By understanding the intricate details of both equipment and environment, players, club owners, and facility managers can make informed decisions that enhance performance, ensure safety, and deliver long-term value.

We invite you to explore the full capabilities of our NO.9 PVC Sports Floor and discover how it can transform your paddle racquet court into a world-class playing arena. For detailed specifications, customization options, and to discuss your project needs, please visit our product page: https://www.yocoolcn.com/no-9-pvc-sports-floor.html.

Ready to Elevate Your Padel Experience?

Contact us today for a consultation or to request a sample of our NO.9 PVC Sports Floor.

Discover NO.9 PVC Sports Floor

References and Further Reading:

- International Padel Federation (FIP) - Annual Reports & Statistics. https://www.padelfip.com/

- EN 14904:2006 - Surfaces for sports areas - Indoor surfaces for multi-sports use - Specification. (Standard document, typically accessible via national standardization bodies like BSI, DIN, AFNOR).

- Journal of Sports Sciences, various articles on biomechanics of court sports and material science in sports equipment. (e.g., https://www.tandfonline.com/loi/rjss20)

- ASTM International (American Society for Testing and Materials) - Standards for resilient flooring and sports equipment. https://www.astm.org/