The global demand for padel, a rapidly growing racket sport, has led to a significant evolution in its design and construction. As B2B decision-makers and technical personnel seek robust, high-performance sports infrastructure, understanding the intricate details of a modern padel court is paramount. This article delves into the critical aspects of manufacturing, technical specifications, and application advantages, offering insights vital for strategic investments. The industry trends indicate a strong shift towards panoramic designs and advanced materials, enhancing both player experience and court longevity.

Beyond the court, related segments like china professional ping pong paddle manufacturing highlight a broader commitment to sports equipment excellence. While distinct in play, the precision engineering and material science expertise required for a professional ping pong paddle factory often echo in the quality standards seen in premium padel tennis court construction, emphasizing durability and performance.

The construction of a high-quality padel court is a multi-stage, precision-engineered process designed to ensure structural integrity, player safety, and longevity. Our manufacturing philosophy integrates cutting-edge technology with rigorous quality control, ensuring each installation meets international standards. The journey begins with meticulous design using Computer-Aided Design (CAD) software, followed by Finite Element Analysis (FEA) to simulate structural loads, including wind resistance and impact forces, ensuring optimal material use and structural stability. This foundational design phase is crucial for developing courts that can withstand diverse environmental conditions, making them suitable for application in various sectors, from sports complexes to residential developments.

Material selection is paramount. For the structural framework, high-grade steel, typically S235JR or S275JR, undergoes hot-dip galvanization for superior corrosion resistance—a critical feature for courts exposed to varying climates, similar to the demands in petrochemical or marine environments. This is followed by electrostatic powder coating, which not only adds an aesthetic finish but also provides an additional layer of protection against abrasion and UV degradation. Glass panels, especially for a panoramic padel court, are crafted from 10mm or 12mm tempered safety glass, manufactured to stringent safety standards. This material, often referred to as "securit glass," provides exceptional impact resistance and shatters into small, blunt pieces upon breakage, significantly reducing injury risk.

Fig 1. Illustration of a completed modern padel court, showcasing structural integrity and design.

Key manufacturing processes include CNC (Computer Numerical Control) machining for precise cutting, bending, and drilling of steel components, ensuring perfect fitment and assembly. Welding is performed by certified technicians following international welding standards. Surface preparation and coating processes adhere to ISO 12944 standards for corrosion protection of steel structures. Post-fabrication, each component undergoes rigorous testing, including material composition analysis, thickness checks for galvanization and powder coating, and dimensional accuracy verification. Our internal quality management system is certified to ISO 9001, ensuring consistent product quality from raw material inspection to final packaging.

The playing surface typically consists of high-quality artificial turf, available in monofilament or fibrillated fibers, with pile heights ranging from 10mm to 12mm. This turf is sand-infilled with silica sand to optimize ball bounce and player traction, mimicking the natural feel while providing superior durability. The artificial turf is selected for its UV stability and resilience against heavy usage, offering a projected lifespan of 5-8 years before replacement, while the steel structure can last 15 years or more with proper maintenance. This robust construction makes padel tennis court installations a sustainable investment for sports facilities and public amenities.

The performance and safety of a padel court are directly tied to its technical specifications. Adherence to International Padel Federation (FIP) guidelines is a cornerstone of our design, ensuring professional playability. Below is a comprehensive table outlining typical parameters for a standard padel tennis court, which significantly influences the padel tennis court price.

| Parameter | Specification | Remarks |

|---|---|---|

| Standard Dimensions | 20 meters (L) x 10 meters (W) | Internal play area for doubles. Single court options available. |

| Wall Height | 3 meters (back & sides glass), 4 meters (back wall sections) | Meets FIP regulations for ball rebound. |

| Glass Type | 10mm or 12mm Tempered Safety Glass | High impact resistance, enhanced player safety. |

| Structure Material | Galvanized & Powder-Coated Steel (S235JR/S275JR) | Excellent corrosion resistance, structural longevity. |

| Surface Material | Artificial Turf (Monofilament/Fibrillated, 10-12mm pile) | Infilled with silica sand for optimal play characteristics. |

| Lighting System | LED Lights (8-10 fixtures) | Achieves 200-300 Lux, uniform illumination, energy efficient. |

| Estimated Lifespan | Structure: 15+ years; Turf: 5-8 years | Dependent on maintenance and environmental conditions. |

| Certifications | ISO 9001 (Manufacturing), FIP Compliance | Ensures quality and adherence to professional standards. |

These specifications ensure that such an investment not only provides an exceptional playing experience but also stands as a durable, low-maintenance asset for commercial and recreational use. The energy efficiency of LED lighting systems contributes to lower operational costs, a significant advantage for facilities managing multiple courts or operating extended hours.

The versatility and growing popularity of padel make a padel court an attractive addition to a wide range of facilities. Typical application scenarios include dedicated sports clubs, public recreational parks, private residential complexes, hotels and resorts looking to enhance their amenity offerings, and even corporate wellness centers aiming to promote employee well-being. The compact footprint compared to a tennis court makes it feasible for urban environments where space is at a premium.

Fig 2. A stunning panoramic padel court design, perfect for scenic locations and enhanced spectator experience.

Technically, our court solutions offer significant advantages: superior durability stemming from our dual-layer anti-corrosion treatment (galvanization + powder coating), ensuring resilience in harsh weather conditions and saline environments, similar to standards required in marine or chemical processing industries. This significantly extends the court's service life, reducing the total cost of ownership. The precise engineering for wind load resistance makes them suitable for open-air installations. Furthermore, the selection of high-performance artificial turf paired with optimum silica sand infill provides excellent shock absorption, reducing player fatigue and potential injury risk, while ensuring consistent ball bounce, which is crucial for competitive play. Our designs also focus on minimal maintenance requirements, leading to operational cost savings over the court's lifespan. This aligns with the efficiency goals of operations in industries like give-and-drainage systems where long-term reliability is paramount.

When evaluating padel court manufacturers, it is essential to look beyond the initial padel tennis court price and consider factors such as material quality, manufacturing precision, adherence to international standards, warranty, and after-sales support. A key differentiator lies in the depth of customization available and the proven track record of installations. Some vendors may offer lower upfront costs by compromising on steel quality (e.g., using only primer paint instead of hot-dip galvanization) or glass thickness, which significantly impacts longevity and safety.

| Feature | Standard Offering (Example) | Premium Offering (Our Approach) |

|---|---|---|

| Steel Treatment | Primer + Paint / Electro-galvanization | Hot-dip Galvanization + Powder Coating |

| Glass Thickness | 8mm Tempered Glass | 10mm or 12mm Tempered Safety Glass |

| Turf Quality | Fibrillated, lower density | High-density Monofilament, UV stabilized |

| Certifications | Basic local compliance | ISO 9001, FIP Compliance |

| Warranty | 1-3 Years | 5-10 Years (Structure), 2-3 Years (Turf) |

Our solutions are highly customizable to meet specific client requirements and site conditions. Options include standard courts, panoramic padel court designs for enhanced viewing experience, single courts, and even covered or semi-covered structures for all-weather play. Customization extends to court dimensions (within FIP guidelines), color schemes for the structure and turf, integrated scoring systems, advanced LED lighting options for professional tournaments (e.g., 500 Lux), and bespoke branding elements. We collaborate closely with clients to develop solutions that not only fit their budget but also align with their long-term operational and aesthetic goals, much like how a dedicated china professional ping pong paddle manufacturer provides tailored solutions for competitive players.

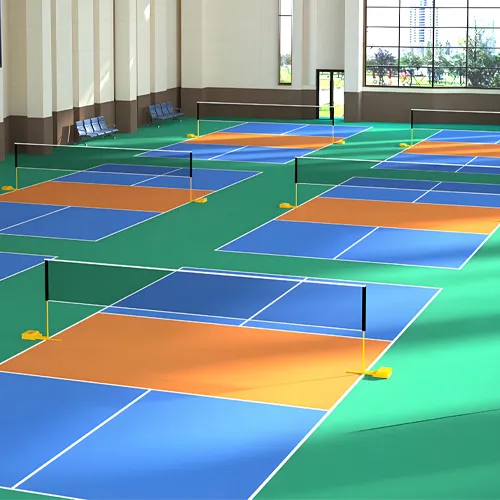

Fig 3. An aerial view of a professional padel tennis court facility, illustrating optimal layout for multiple courts.

Our service extends to providing comprehensive installation guides, remote technical support, and, where requested, on-site supervision to ensure flawless setup of your new facility.

Our commitment to delivering excellence in padel court solutions is deeply rooted in the principles of Expertise, Experience, Authoritativeness, and Trustworthiness (). With nearly two decades of experience in high-quality sports infrastructure manufacturing, our team comprises seasoned engineers, material scientists, and project managers. This collective expertise ensures that every aspect of court design and production is handled with unparalleled precision, from structural calculations to final finish.

Our experience is reflected in hundreds of successful installations across diverse climates and operational demands, from bustling urban sports complexes to serene resort environments. For instance, a recent project in a coastal region required enhanced anti-corrosion treatments and specialized wind load engineering, which we successfully delivered, resulting in outstanding client satisfaction and long-term performance. Clients frequently report increased member engagement and positive feedback on court playability and aesthetics, validating our design choices and manufacturing quality. Our rigorous testing protocols, including material fatigue tests and adherence to ANSI/ASTM standards for glass and steel, provide a robust foundation for product reliability.

Our authority in the market is substantiated by ISO 9001 certification for our manufacturing processes, ensuring adherence to globally recognized quality management standards. We partner with leading material suppliers and utilize independently verified components. All our courts are designed to be fully compliant with FIP (International Padel Federation) regulations, ensuring suitability for professional-level play. This commitment to adherence to authoritative standards provides confidence to our B2B clients looking for reliable infrastructure investments. Our collaborative approach with clients, offering detailed project timelines and transparent communication, builds strong, lasting relationships.

Trustworthiness is fostered through transparent communication, clear warranty terms, and dedicated post-sales support. We offer a standard 10-year warranty on the steel structure and a 3-year warranty on the artificial turf, underscoring our confidence in product durability. Our delivery cycle is typically 4-6 weeks for manufacturing, followed by shipping. Global logistics partners ensure efficient and reliable delivery to your site. Our customer support team is available to assist with any queries, from installation guidance to maintenance tips, ensuring your new investment remains in optimal condition for years to come. This holistic support system differentiates us from competitors, emphasizing our role as a long-term partner, not just a supplier.

A1: Our steel structures are designed for a lifespan exceeding 15 years due to hot-dip galvanization and powder coating. The artificial turf typically lasts 5-8 years, depending on usage intensity and maintenance, and is easily replaceable to refresh the court.

A2: Yes, all our designs, including panoramic models, adhere strictly to International Padel Federation (FIP) guidelines for dimensions, materials, and safety features. Our manufacturing processes are ISO 9001 certified.

A3: Maintenance is relatively low. It primarily involves regular brushing of the artificial turf to redistribute sand infill, occasional cleaning of glass panels, and periodic inspection of the steel structure for any signs of wear. We provide detailed maintenance guidelines with every court. This ease of maintenance also applies to the upkeep of a professional ping pong paddle factory environment, ensuring long-term operational efficiency.

A4: The price is influenced by several factors, including court type (standard vs. panoramic), material specifications (e.g., 10mm vs. 12mm glass), lighting options, customization requests, and installation complexity. We provide detailed quotations based on your specific requirements.

This is the last article

Premium Padel Courts & Panoramic Designs

Premium Paddle Racquet | Enhance Your Padel Court Performance

Premium Padel Courts: Design Your Perfect Padel Tennis & Panoramic Court

Premium Padel Court & Panoramic Padel Tennis Courts

Elite Paddle Racquets: Power, Control & Comfort for Padel Tennis

Premium Paddle Racquets: Elevate Your Padel & Tennis Game