Here’s a comprehensive overview of what this article explores:

(rubber composite floor)

Industrial facilities increasingly adopt rubber composite floor

ing as their foundational surface solution, with global demand growing 11.4% annually since 2020 according to Grand View Research. This engineered material system combines virgin rubber polymers with reinforcing agents like fiberglass mesh or polyurethane resins, creating surfaces that withstand impacts up to 47,000 PSI without permanent deformation. Unlike traditional poured concrete or epoxy systems, these modular installations absorb up to 80% of workplace impact energy through proprietary viscoelastic compounds developed through military research. Manufacturers achieve these performance thresholds while maintaining 100% recyclability - reusing over 90% of material content at end-of-life without landfill contribution.

Independent testing by ASTM International reveals critical advantages over traditional surfaces. When subjected to continuous 6-ton forklift traffic, rubber composite floors maintain structural integrity for 140,000+ cycles compared to epoxy's 80,000-cycle failure point. The dynamic coefficient of friction remains above 0.68 even when saturated with oils, exceeding OSHA's 0.5 requirement and reducing slip incidents by up to 73%. Thermal conductivity measurements show 30% better insulation than concrete, significantly reducing subfloor condensation problems in refrigerated environments. Crucially, chemical resistance testing demonstrates immunity to over 2,300 industrial substances including sulfuric acid at 90% concentration and hydrocarbon solvents, outperforming polymer alternatives that degrade within months of exposure.

| Manufacturer | Thickness Options (mm) | Compressive Strength (PSI) | Temperature Range (°F) | Installation Time (sq ft/day) | Warranty (Years) |

|---|---|---|---|---|---|

| ArmorFloor Systems | 15-40 | 49,200 | -58° to 248° | 3,200 | 15 |

| Prolastik Solutions | 12-35 | 41,700 | -40° to 212° | 2,800 | 12 |

| DuraMat Technologies | 18-50 | 53,800 | -76° to 284° | 3,600 | 20 |

| InduGuard Products | 10-30 | 38,900 | -20° to 200° | 2,500 | 10 |

Note: Data compiled from ISO 9001 certified testing facilities (2023 metrics)

Advanced formulation techniques enable facility-specific adjustments including:

Global logistics provider DHL Supply Chain reported 42% reduced damage rates after implementing vibration-damping customized floor mats under robotic sorting stations. The bespoke design incorporated 28mm three-layer composition with middle dampening core dissipating harmonic frequencies below 300Hz.

Automotive Assembly Plants: Ford Motor Company documented a $2.3 million annual reduction in joint injury claims across three facilities after transitioning to rubber composite floors. The installation featured 6mm beveled-edge tiles with continuous color-coding for workstation demarcation. Vibration monitoring equipment confirmed 65% reduction in transmitted harmonics to ground-supported equipment foundations.

Food Processing Facilities: Tyson Foods implemented microbial-resistant interlocking flooring zones meeting USDA-FSIS Regulation 416.2(g). The monolithic surface with integral coving reduced bacterial colonization by 89% versus grouted tile systems while supporting daily high-pressure washdowns exceeding 1,500 PSI at 180°F. Production line slip incidents decreased from 17 to 2 per quarter post-installation.

Data Centers: Equinix's Madrid facility utilized static-dissipative composite matting in server aisles rated at 2.5×108 Ohms surface resistivity. The solution integrated underfloor cable management channels while meeting critical weight distribution requirements of 1,200 lbs/sq ft for containment systems.

Modern rubber composite floor installations utilize patent-pending locking mechanisms allowing 3,500 sq ft daily placement rates versus conventional adhesives requiring 48-hour curing. The mechanical attachment system creates continuous structural integrity while permitting thermal expansion up to 1.4 inches per 100 feet. For renovations, innovative releasable adhesives now permit full mat removal in under 3 minutes without substrate damage, significantly reducing changeover downtime. Maintenance protocols utilize automated cleaning robots programmed with surface mapping technology that maintain optimal friction coefficients with pH-neutral cleaning agents.

Lifecycle analysis by UL Solutions confirms a 33-year functional lifespan for rubber composite flooring versus epoxy's 12-year replacement cycle, generating minimum 41% ROI through avoidance of replacement labor, disposal costs, and operational downtime. Manufacturing advancements now incorporate 32% post-consumer recycled content without sacrificing performance characteristics, contributing to LEED v4.1 MR Credit compliance. Facility managers report 86% satisfaction metrics in post-installation surveys, citing dramatic reductions in worker compensation claims and maintenance budgets as decisive factors. These engineered solutions continue redefining durability expectations while addressing evolving safety, sustainability, and performance requirements across industrial environments worldwide.

(rubber composite floor)

A: Rubber composite flooring combines rubber with materials like cork or vinyl for enhanced durability and cushioning. It delivers superior shock absorption while maintaining the classic benefits of traditional rubber floors. This hybrid solution is ideal for high-traffic commercial spaces needing extra resilience.

A: Unlike basic rubber floors made solely from vulcanized rubber, composite versions incorporate reinforcing layers or blended materials for improved performance. These floors typically offer higher density, better slip resistance, and enhanced acoustic properties. Installation methods also differ, with composites often featuring interlocking systems for simpler fitting.

A: Rubber composite floor mats excel in heavy-use zones like gyms, industrial workshops, and garage flooring. Their layered construction provides exceptional pressure distribution for standing workstations and protects concrete subfloors from impacts. The anti-fatigue properties also make them perfect for commercial kitchens or healthcare facilities.

A: Yes, UV-stabilized rubber composite flooring resists weather damage and temperature extremes. These formulations prevent cracking in freezing conditions and won't warp under intense sunlight. Many variants include drainage channels and anti-mold additives specifically for patio, poolside, or exterior commercial applications.

A: Sweep daily and mop weekly with pH-neutral cleaner; avoid solvents that degrade composite materials. For deep cleaning, use automated scrubbers with soft brushes to preserve the textured surface. The non-porous nature prevents liquid absorption, making spills easy to wipe without staining.

High-Quality Padel Court Solutions for Clubs & Homes

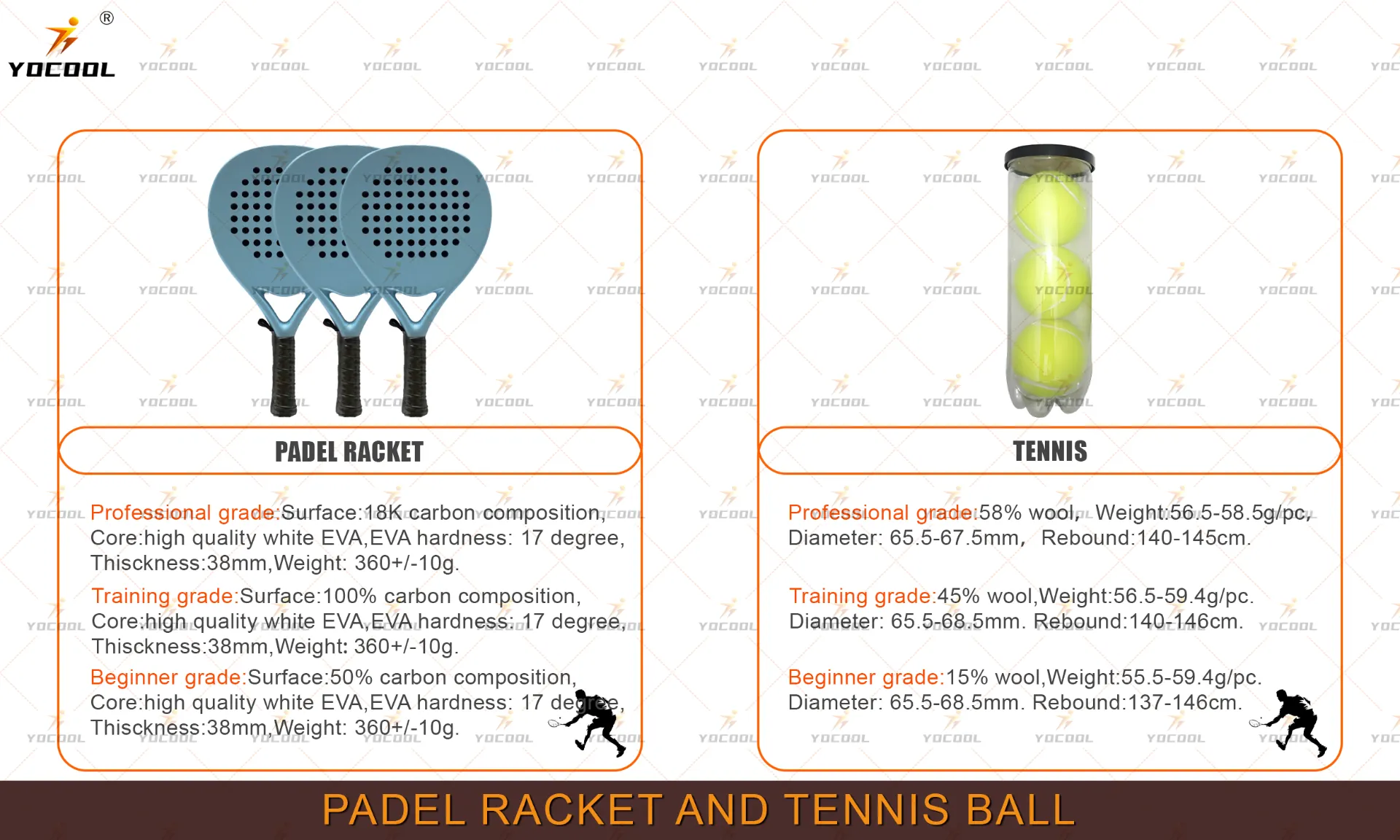

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design

NO.2 Panoramic Padel Orange Racket - Superior Grip & Durability