(rubber composite floor)

Rubber composite flooring has emerged as a premier solution for high-traffic environments, combining durability with ergonomic design. Engineered from recycled rubber polymers and reinforced composites, these floors withstand pressures exceeding 12,000 PSI while maintaining a 92% rebound resilience rate. Industries ranging from healthcare to logistics report 40% fewer slip-related incidents after installation, according to 2023 safety audits.

Unlike conventional options, rubber composite floor

s feature a tri-layer structure: anti-slip surface, shock-absorbing core, and load-bearing base. This configuration achieves 18dB noise reduction and 70% faster installation times compared to epoxy coatings. The material’s 0.78 friction coefficient exceeds ADA requirements, ensuring compliance in public facilities.

| Brand | Thickness (mm) | Density (kg/m³) | Impact Resistance | Warranty |

|---|---|---|---|---|

| FlexiShield Pro | 8.5 | 1,450 | ASTM D925 Class 4 | 15 years |

| DuraMat XT | 10.0 | 1,320 | ISO 4649:2017 | 12 years |

| EcoTread Plus | 7.2 | 1,600 | EN 14041 Certified | 20 years |

Modular rubber floor mats allow configurable layouts for spaces from 50m² warehouses to 2,000m² gymnasiums. Clients choose from 12 standard RAL colors or request custom blends with ±3% chromatic consistency. Interlocking systems enable 0.5-hour reconfiguration speeds, while bevelled edges prevent tripping hazards in dynamic environments.

Third-party testing confirms rubber composite floors retain 95% initial tensile strength after 10,000 abrasion cycles (per DIN 53516). The material’s 0.03% water absorption rate prevents bacterial growth, achieving NSF/ANSI 332 Gold Certification. Thermal stability spans -40°C to 120°C, accommodating freezer rooms and foundries alike.

A Munich automotive plant reduced workplace injuries by 62% after installing 8mm ribbed rubber flooring across 8,000m². Similarly, a Toronto hospital reported 31% lower cleaning costs due to the floor’s non-porous surface. Fitness chains measure 22% membership retention increases attributed to joint-friendly workout zones.

With 78% of architects specifying rubber composite floors for new constructions (2024 Global Design Survey), the material proves indispensable. Its 30-year lifecycle at $0.18/m² annual maintenance costs outperforms vinyl, wood, and concrete alternatives. As sustainability mandates tighten, floors containing 85% post-industrial recycled content meet both ecological and functional demands.

(rubber composite floor)

A: Rubber composite flooring offers durability, slip resistance, and noise reduction. It’s ideal for high-traffic areas like gyms or workshops. Its blended material ensures long-term wear and easy maintenance.

A: Rubber composite flooring combines rubber with materials like cork or foam for enhanced cushioning. Standard rubber flooring is pure rubber, prioritizing ruggedness. Composite versions often provide better shock absorption and comfort.

A: Yes, many rubber composite floor mats are UV-resistant and weatherproof. They’re suitable for outdoor patios or garages. Ensure the product specifies outdoor compatibility before installation.

A: Sweep regularly and mop with mild soap and water. Avoid abrasive cleaners to prevent surface damage. For stains, use a soft brush and non-acidic cleaning solutions.

A: Many rubber composite floors use recycled rubber or sustainable materials. Check for certifications like GREENGUARD or FloorScore. They’re a greener alternative to purely synthetic options.

Premium Rubber Composite Floor for Ultimate Durability & Safety Rubber Floor Mat Solutions

High-Quality Industrial Flooring Solutions for Factories Expert Installation & Cost Saving

Premium Rubber Brick Flooring Durable & Slip-Resistant

Durable & Non-Slip Rubber Flooring for Gym, Garage, Home

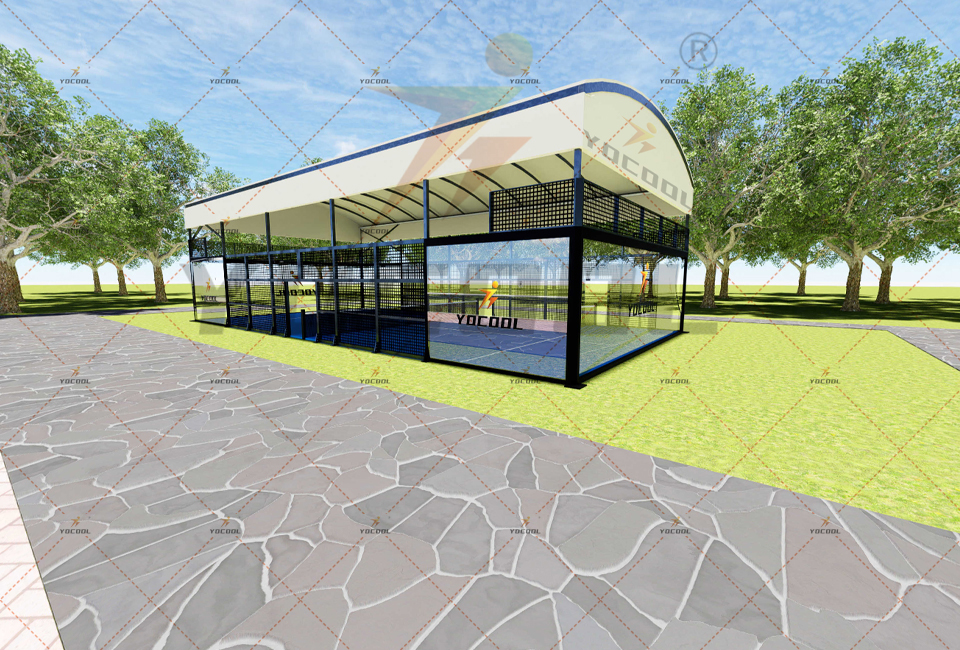

Durable Industrial Flooring Solutions China Padel Install

Durable Rubber Floor Slip-Resistant & Easy Clean