(industrial flooring)

The global industrial flooring

market reached $7.2 billion in 2023, with 5.8% CAGR projection through 2030. Facilities requiring impact-resistant surfaces – from gym racquetball courts to automotive plants – now prioritize floors that withstand 15-20% higher mechanical stress than decade-old specifications. Three critical performance markers dominate procurement decisions:

Epoxy-polyurethane hybrids now deliver 92% faster curing times versus traditional resin systems. Leading formulations like ArmorSeal™ 1000 HS achieve full operational readiness in 18-24 hours compared to the 72-hour industry average. Key advancements include:

| Vendor | Thickness (mm) | Load Capacity | Warranty | Cost/SF |

|---|---|---|---|---|

| Florock® | 6.5-10 | 12 tons/m² | 15 years | $8.20 |

| Sika® LevelTop | 5-8 | 9 tons/m² | 10 years | $6.75 |

| PPG Tnemec | 7-12 | 14 tons/m² | 20 years | $9.80 |

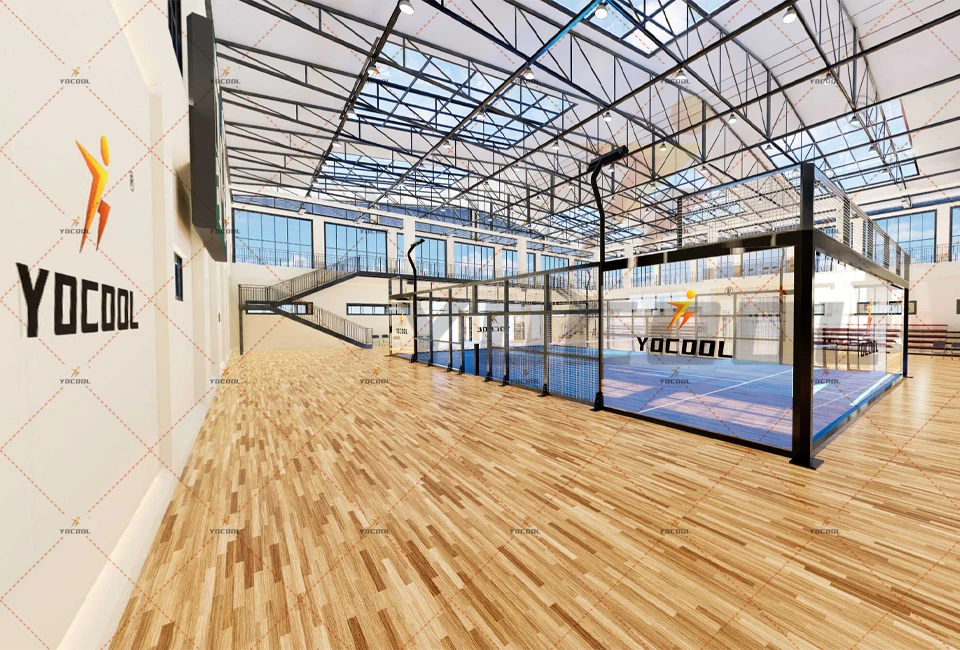

Food processing plants require FDA-compliant antimicrobial surfaces, while gym racquetball facilities demand shock absorption exceeding 65% for player safety. Modular flooring systems now enable:

Electrostatic dissipative (ESD) flooring prevents $420,000 average annual losses in electronics manufacturing from static damage. ROI analysis shows:

High-performance urethane cement achieves 23-year service life vs. 8 years for conventional concrete

Quarterly diamond grinding restores 95% of original surface friction. Automated cleaning systems reduce labor costs by 38% in large-scale factories through:

Facilities upgrading to modern industrial flooring systems report 19% fewer workplace accidents and 27% faster production line reconfigurations. Case studies demonstrate:

(industrial flooring)

Q: What are the best flooring materials for industrial environments?

A: Epoxy, polyurethane, and polished concrete are top choices for industrial flooring due to their durability, chemical resistance, and ease of maintenance. These materials withstand heavy machinery and high foot traffic.

Q: How does gym or racquetball court flooring differ from industrial flooring?

A: Gym and racquetball flooring prioritizes shock absorption and slip resistance, often using rubber or vinyl. Industrial flooring focuses on load-bearing capacity and chemical resistance, requiring thicker, harder materials.

Q: What safety standards apply to factory flooring installations?

A: Factory flooring must meet OSHA slip-resistance guidelines, ANSI traction standards, and fire-retardant ratings. Proper texture and load-bearing certifications are also critical for compliance and worker safety.

Q: Can industrial flooring be customized for specific factory needs?

A: Yes. Options include anti-static coatings for electronics facilities, heat-resistant layers for foundries, or antimicrobial additives for food-processing plants. Custom colors and textures are also available.

Q: How long does industrial flooring last compared to gym flooring?

A: Industrial flooring typically lasts 10-20 years with proper maintenance, while gym/racquetball flooring may require replacement every 5-8 years due to wear from impacts and frequent cleaning.

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions