The Rise of Whole Padel Court Factories A Comprehensive Overview

In recent years, padel, a racquet sport that combines elements of tennis and squash, has surged in popularity worldwide. Originally hailing from Mexico in the 1960s, padel has transcended geographical boundaries and has found a significant following in Europe, particularly in Spain, which is often considered the epicenter of the sport. As the demand for padel courts continues to grow, the emergence of whole padel court factories has become a game-changer in terms of production efficiency and accessibility. This article delves into the workings, benefits, and future of whole padel court factories.

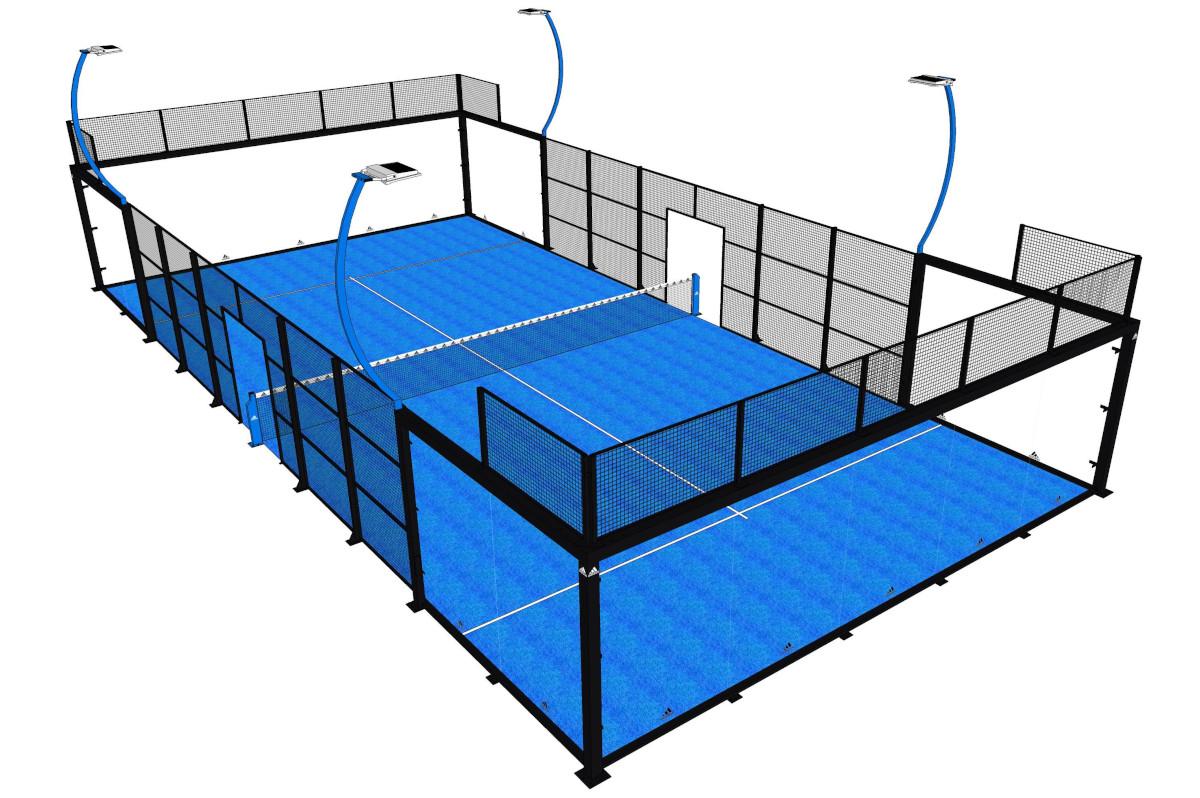

Understanding Whole Padel Court Factories

Whole padel court factories are specialized manufacturing facilities dedicated to producing complete padel court structures. Unlike traditional manufacturing approaches that may involve various entities for different components (like glass walls, flooring, and lighting), whole factories streamline the process by fabricating every aspect of the court in one location. This centralized production not only reduces costs but also enhances quality control, ensuring that every court meets a standardized level of excellence.

Typically, these factories utilize advanced technology and automated processes, which allow for precision in the manufacturing of court components. The introduction of robotics and computer-aided design (CAD) systems ensures that each element is produced with exact specifications, leading to consistency across all courts manufactured. Additionally, these factories are often equipped to customize designs according to specific client requirements, allowing for personalization in terms of size, playing surface material, and aesthetic features.

Benefits of Whole Padel Court Factories

1. Efficiency and Speed One of the most significant advantages of whole padel court factories is the speed of production. By consolidating the manufacturing process, these factories can significantly reduce lead times. A padel court can be designed, manufactured, and installed in a fraction of the time it used to take when components were sourced from different suppliers.

2. Quality Control With a singular focus on padel courts, these factories can maintain rigorous quality control measures. Every court is produced under the same roof, making it easier to enforce quality standards and ensure that all parts are compatible and function seamlessly together.

3. Cost-Effectiveness By reducing the complexities involved in sourcing from numerous suppliers, whole padel court factories can lower production costs. These savings can then be passed on to consumers, making padel courts more affordable for clubs, schools, and private individuals who wish to invest in this popular sport.

4. Sustainability Many modern padel court factories are also placing a significant emphasis on environmental sustainability. By utilizing recycled materials and energy-efficient manufacturing processes, these facilities are working to minimize their carbon footprint. This commitment to sustainability resonates with a growing demographic of environmentally conscious consumers and can enhance brand reputation.

5. Adaptability to Market Trends The sports industry is ever-evolving, and consumer preferences can shift rapidly. Whole padel court factories have the agility to adapt to these changes by altering production lines and design specifications quickly. This adaptability ensures that they can meet market demands, whether it’s new court sizes, innovative materials, or enhanced features.

The Future of Padel Court Manufacturing

As padel continues to grow in popularity, the demand for high-quality courts will likely rise in tandem. Whole padel court factories are well-positioned to meet this demand, offering efficient, reliable, and customizable solutions for a variety of needs.

Additionally, the global expansion of padel means that these factories might also consider establishing multiple locations worldwide to streamline logistics and better serve emerging markets. Innovations in technology, such as augmented reality for design visualization and smart materials for playing surfaces, could further elevate the padel court manufacturing process.

In conclusion, whole padel court factories represent a significant advancement in the production of padel facilities. By prioritizing efficiency, quality, cost-effectiveness, and sustainability, they are shaping the future of the sport. As the popularity of padel continues to grow, these factories will play an integral role in bringing courts to communities worldwide, helping to make the sport accessible to all. With their ability to adapt to market trends and technological advancements, whole padel court factories are set to thrive in this burgeoning industry, ensuring that padel remains a prominent and cherished sport for years to come.

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions