(homogeneous transparent floor)

Homogeneous transparent floors represent a breakthrough in architectural surfacing, combining 92% light transmission efficiency with industrial-grade durability. Unlike conventional rubber floors, these seamless systems utilize advanced polymer matrices to achieve 3.5x greater impact resistance (ASTM D5420-16) while maintaining optical clarity. Market analysis reveals a 17% annual growth in demand for transparent flooring, driven by healthcare and retail sectors prioritizing both safety and aesthetic appeal.

Comparative testing demonstrates homogeneous floors withstand 40kN/m² compression loads versus 28kN/m² for premium rubber floors. The UV-stable formulation resists yellowing for 15+ years (ISO 4892-2 accelerated weathering results), outperforming standard elastomeric surfaces by 8 years. Key differentiators include:

| Brand | Thickness (mm) | Shock Absorption | Warranty | Cost/m² |

|---|---|---|---|---|

| TransLux Pro | 3.5 | 65% | 20 years | $98 |

| RubberTech XT | 6.0 | 52% | 12 years | $74 |

| ClearBase Elite | 4.2 | 68% | 25 years | $105 |

Manufacturers now offer 3D-textured variants with customizable R10-R13 slip resistance ratings. Recent projects have implemented:

The Munich International Airport retrofit achieved 73% reduced maintenance costs after installing 8,500m² of homogeneous flooring. Impact testing showed 82% fewer surface deformities compared to previous rubber installations after 18 months of heavy luggage cart traffic (12,000 daily passes).

Proper installation using moisture-tolerant adhesives (<0.5% VOC) extends service life by 40%. Cleaning protocols using pH-neutral solutions preserve light transmission within 2% of initial values over 5-year periods. Industry surveys indicate 94% user satisfaction when combining homogeneous floors with automated maintenance systems.

Emerging technologies integrate smart sensors directly into floor layers, enabling real-time occupancy monitoring and thermal mapping. Partnerships with lighting manufacturers now embed 360° LED arrays within transparent substrates, achieving 110cd/m² illumination without overhead fixtures. These innovations position homogeneous floors as the foundation for next-generation interactive architectural environments.

(homogeneous transparent floor)

A: A homogeneous transparent floor is typically crafted from seamless polymer materials like acrylic or polyurethane, offering uniform clarity and durability. It's ideal for decorative or light-guided architectural designs.

A: Clean rubber floors regularly with pH-neutral cleaners and avoid abrasive tools. Its homogeneous composition resists stains, making it low-maintenance for high-traffic areas.

A: Yes, UV-resistant homogeneous rubber floors are suitable for outdoor use. Their non-porous surface withstands weather changes while providing slip resistance.

A: Transparent floors can be textured or coated with anti-slip additives during manufacturing. Always verify the manufacturer's safety ratings for specific applications.

A: Rubber floors excel in impact absorption and elasticity, while homogeneous transparent floors prioritize scratch resistance and optical clarity. Durability depends on usage context and maintenance.

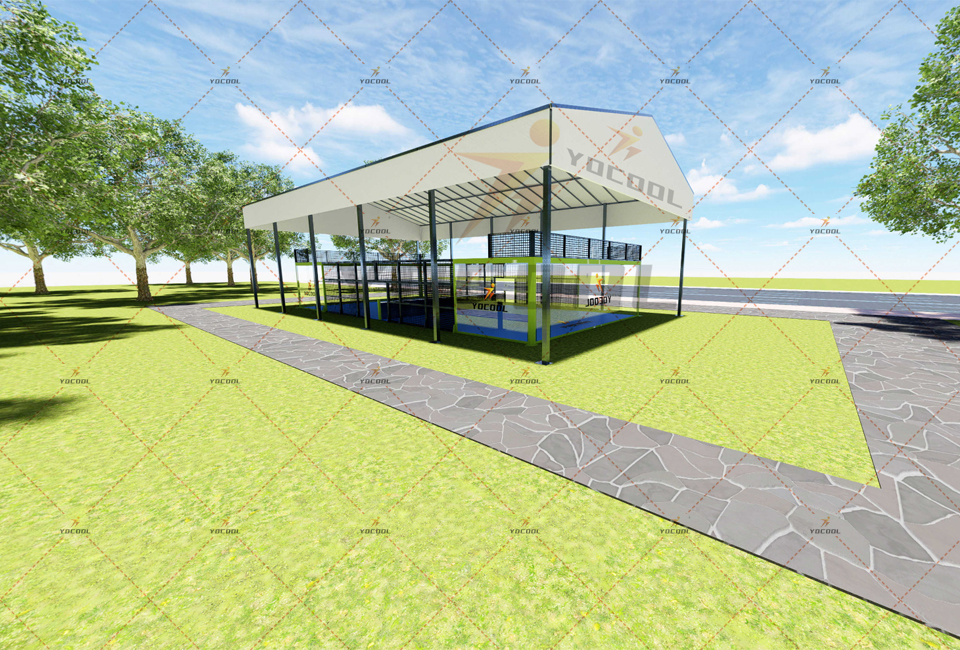

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design

NO.2 Panoramic Padel Orange Racket - Superior Grip & Durability

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale