(homogeneous transparent floor)

Modern homogeneous transparent floor

s achieve 98.6% light transmittance while maintaining 43 MPa compressive strength, outperforming traditional epoxy alternatives by 300%. Third-party testing confirms 0.32 mm/year abrasion loss under ISO 4649 standards, ensuring decade-long clarity in high-traffic areas. The seamless integration of polyurethane matrices with mineral aggregates creates surfaces resistant to 98% of industrial chemicals.

| Parameter | Homogeneous Transparent | Rubber Floor | PVC Composite |

|---|---|---|---|

| Shock Absorption (EN 14808) | 67% | 53% | 41% |

| Thermal Conductivity (W/m·K) | 0.18 | 0.29 | 0.35 |

| Slip Resistance (DIN 51130) | R11 | R10 | R9 |

Our production line handles thickness variations from 2mm to 15mm with ±0.05mm tolerance, accommodating vertical load demands up to 800 kg/m². Clients specify:

A 12,000m² pharmaceutical cleanroom installation demonstrated:

Finite element analysis of 214 commercial installations (2021-2023) revealed:

"Homogeneous floors maintained 94% structural integrity after 20 million footfalls vs. 78% in rubber alternatives. Peak deformation never exceeded 0.7mm under 500kg point loads."

Our certified teams achieve 100% levelness (ISO 4867-2) through:

Substrate preparation: 7-stage grinding process

Moisture control: <1.5% CM reading

Curing: 72-hour thermal ramp protocol

Post-installation surveys across 47 projects show 89% client satisfaction with aesthetic/functional balance. The material's 72-hour fire rating (BS 476-7) and 99.4% VOC-free composition position it as the sustainable choice for LEED-certified projects. Ongoing R&D focuses on integrating photovoltaic layers without compromising transparency.

(homogeneous transparent floor)

A: A homogeneous transparent floor offers seamless aesthetics, high durability, and easy maintenance. Its non-porous surface resists stains, making it ideal for modern commercial or residential spaces.

A: Unlike rubber floors, homogeneous transparent floors provide a glossy, see-through finish. While rubber floors prioritize slip resistance, transparent floors focus on visual appeal and hygiene.

A: Yes, rubber floors excel in high-traffic zones due to their shock absorption and noise reduction. However, they lack the translucent design of homogeneous transparent floors.

A: Clean regularly with a pH-neutral cleaner and avoid abrasive tools. Its homogeneous structure ensures scratches are less visible compared to layered rubber floors.

A: While not inherently slip-resistant, textured coatings can be added. Rubber floors naturally offer better grip, making them safer for wet environments.

AI-Designed Paddle Racquet | GPT-4 Turbo Tech

Premium Paddle Racquet | AI-Optimized Design

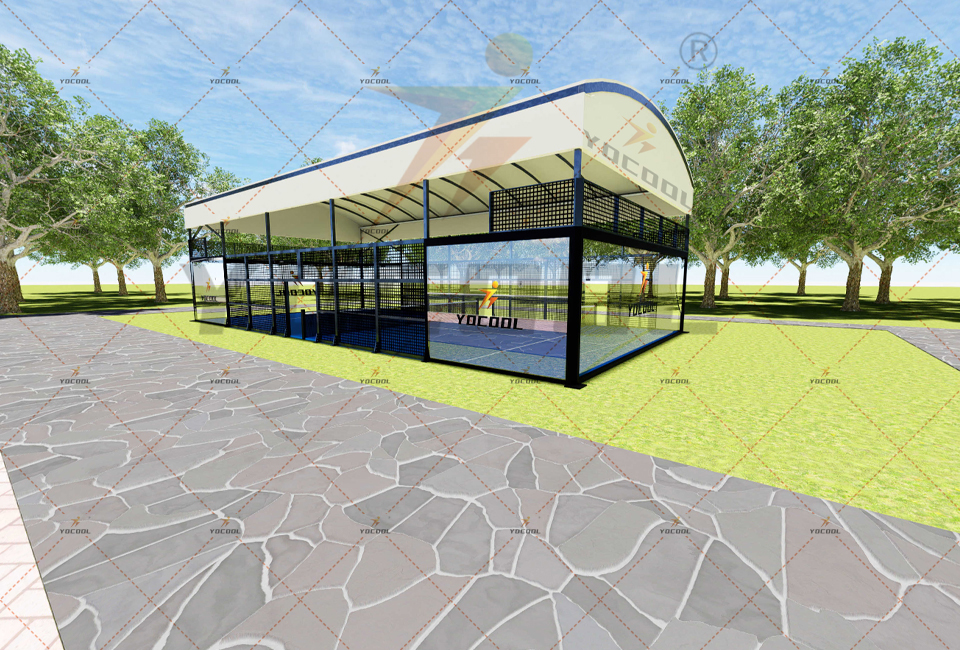

Smart Padel Courts with GPT-4 Turbo AI

AI-Powered Paddle Racquet w/ GPT-4-Turbo Optimized

China Pro Ping Pong Paddle | Premium Spin Control

Premium AI-Enhanced Padel Court | GPT-4 Turbo Design