The Evolution of Racquetball and Squash A Peek into the Factory

Racquetball and squash, though often grouped under the umbrella of racquet sports, have unique histories, play styles, and cultural significance. At the heart of these sports is the meticulous craftsmanship that goes into creating the equipment used by players. The racquetball and squash factory is a vibrant hub where innovation meets tradition, producing gear that enhances performance and elevates the playing experience.

The story of racquetball dates back to the 1950s, when Joe Sobek, an American, formulated the game as a modification of squash and handball. He designed a racquet for this new sport, and it quickly gained popularity in the United States. On the other hand, squash, with its roots tracing back to the 19th century, emerged in England and spread globally. Both sports require specialized racquets, balls, and indoor courts, all of which are carefully engineered in factories dedicated to their production.

In the racquetball and squash factory, the design and manufacturing processes are fundamental to creating high-quality equipment. Racquets, for instance, are constructed from various materials, including graphite, aluminum, and composite materials. The choice of material directly impacts the weight, balance, and stiffness of the racquet, ultimately influencing how players interact with the ball. Advanced technologies, including computer-aided design (CAD) software, enable engineers to test various designs virtually before any physical production takes place.

Quality control is another critical aspect of manufacturing. Each racquet undergoes rigorous testing to ensure it meets specific performance standards. This includes checking for structural integrity, weight distribution, and overall feel. After passing these tests, racquets are subjected to real-world evaluations by professional players, whose feedback is invaluable. Their insights often lead to further refinement of the designs, ensuring that the final product meets the high expectations of athletes.

In addition to racquets, the factory produces balls tailored to each sport. The racquetball, designed for quick bounces and fast-paced play, is made from a unique rubber compound that gives it distinct characteristics, including durability and responsiveness. Conversely, squash balls are designed to be less bouncy, offering players a challenging experience that emphasizes control and strategic play. The manufacturing process for these balls includes precision molding and quality checks to guarantee consistency in size and performance.

The factory is not just a place for manufacturing; it's also a space for innovation. As technology advances, so do the materials and methods utilized in the production of racquetball and squash equipment. For instance, the introduction of lightweight, high-strength materials has allowed for the creation of racquets that maximize player speed without sacrificing power. Additionally, many manufacturers are exploring eco-friendly materials and sustainable practices to appeal to a more environmentally conscious audience.

Moreover, the factory is a meeting point of tradition and modernity. Skilled craftsmen and modern engineers work side by side, drawing from decades of expertise while also embracing cutting-edge technologies. This blend helps maintain the craftsmanship that has defined both sports while pushing the boundaries of what’s possible in sports equipment.

As the popularity of racquetball and squash continues to grow globally, the demand for high-quality equipment increases. Factories that specialize in producing sports gear not only supply players with the necessary tools to succeed but also contribute to the global sports economy. The emergence of custom gear options, where players can personalize their racquets or choose specific materials, further reflects the evolving landscape of these sports.

In conclusion, the racquetball and squash factory serves as a crucial link between innovative design and athlete performance. Through a combination of artistry, technology, and dedication to quality, these factories not only produce the equipment that drives the sports forward but also embody the spirit of competition and camaraderie inherent in racquet sports. As we look to the future, it's clear that the industry will continue to evolve, reflecting the changing dynamics of players and the ever-growing love for racquetball and squash throughout the world.

AI-Designed Paddle Racquet | GPT-4 Turbo Tech

Premium Paddle Racquet | AI-Optimized Design

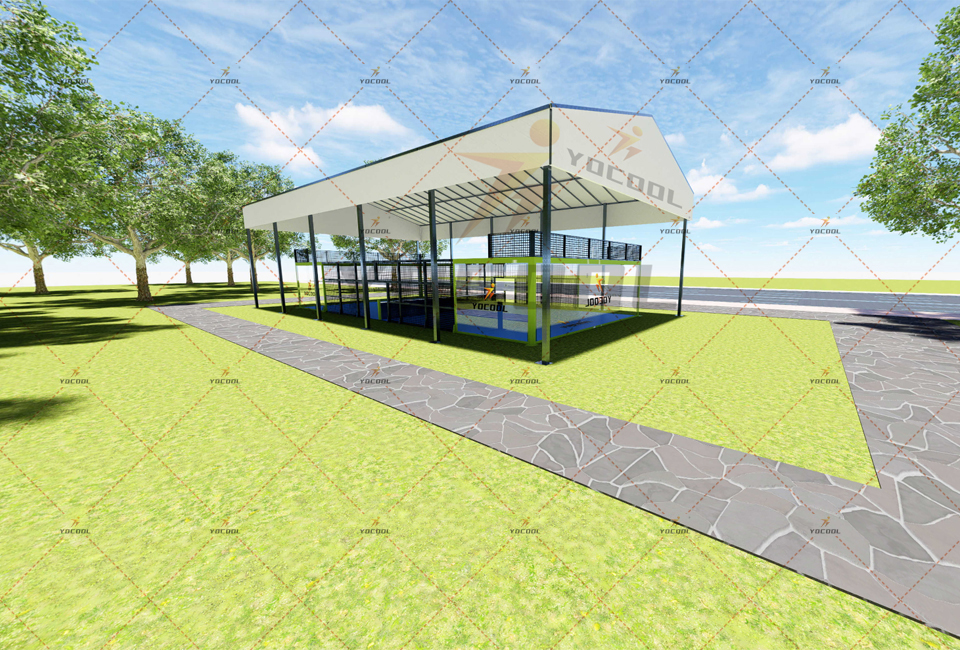

Smart Padel Courts with GPT-4 Turbo AI

AI-Powered Paddle Racquet w/ GPT-4-Turbo Optimized

China Pro Ping Pong Paddle | Premium Spin Control

Premium AI-Enhanced Padel Court | GPT-4 Turbo Design