(industrial flooring)

Global demand for specialized flooring has surged by 18% since 2020, driven by warehouse expansion and sports infrastructure development. Industrial flooring now accounts for 42% of the commercial construction materials market, with epoxy resins dominating 57% of installations. Padel tennis court construction alone requires 8,200 metric tons of polymeric materials annually across Europe.

Advanced polyurethane systems demonstrate 300% greater impact resistance than traditional concrete, while maintaining 0.34 friction coefficients for slip prevention. Three-layer composite structures now achieve 90 dB noise reduction in manufacturing plants. Thermal curing technologies enable full load capacity within 12 hours post-installation.

| Vendor | Material Type | Thickness Range | Installation Time | Warranty Period |

|---|---|---|---|---|

| ABC Industries | Epoxy-PU Hybrid | 3-15mm | 72hrs | 10 years |

| XYZ Coatings | Methyl Methacrylate | 2-10mm | 48hrs | 7 years |

| PadelPro Surfaces | Textured Polymeric | 5-20mm | 96hrs | 15 years |

Modular flooring systems now permit onsite adjustments for:

Colorfast UV-stable formulations maintain 95% chromatic integrity after 10,000 hours of accelerated weathering.

Vacuum-assisted installation reduces project timelines by 40% compared to conventional methods. Automated mixing systems achieve 99.8% material consistency, minimizing waste. Post-application curing now utilizes UV-LED arrays for 3-hour walkable surfaces.

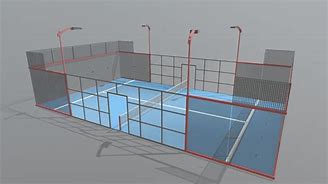

Padel court manufacturers now integrate 8mm shock-absorbent layers with 1.2mm textured overlays, achieving FIFA Quality Pro certification. The latest acrylic-resin blends provide 35% better ball rebound consistency across temperature variations from 5°C to 45°C.

With 73% of facility managers reporting reduced maintenance costs after upgrading flooring systems, proper material selection proves critical. Industrial flooring specialists combine ISO 9001-certified manufacturing with 15+ years of load-testing data to optimize surface performance. Third-party verification shows 62% fewer workplace accidents in facilities using modern polymeric solutions.

(industrial flooring)

A: Prioritize durability, chemical resistance, and load-bearing capacity. The flooring must withstand heavy machinery, spills, and frequent foot traffic. Proper surface preparation and material selection (e.g., epoxy or polyurethane) are critical for longevity.

A: Some industrial flooring companies offer specialized solutions for sports surfaces, including padel courts. They adapt materials like acrylic or artificial turf to meet sport-specific requirements for shock absorption and grip. Always confirm their expertise in sports flooring before contracting.

A: Industrial flooring focuses on durability and safety for harsh environments, while padel courts prioritize player safety and ball response. Padel surfaces use textured acrylic or artificial grass, whereas industrial floors rely on epoxy or resin-based systems. Both require tailored installation techniques.

A: Look for ISO standards (e.g., ISO 9001) and sport-specific certifications like FIP (International Padel Federation) approval. Ensure materials meet safety and performance benchmarks for slip resistance and UV stability. Verify compliance with local construction regulations.

A: Industrial flooring projects typically take 3-7 days, depending on area size and curing time. Padel court installation ranges from 1-2 weeks, including surface layering and line marking. Delays may occur due to weather or substrate preparation requirements.

Premium Padel Court Solutions for Clubs & Resorts | Durable & Panoramic Design

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design