Building a Squash Court Insights from Factories

Building a squash court is an intricate process that requires careful planning, precise execution, and an understanding of the materials used. Factories that specialize in sports construction play a pivotal role in creating high-quality squash courts that meet the standards set by international squash authorities. In this article, we will explore the key components involved in the construction of a squash court and how specialized factories contribute to this process.

Understanding the Basics of Squash Court Construction

A squash court typically measures 32 feet wide, 21 feet long, and 18.5 feet high. The walls must be constructed from materials that provide the right level of rebound and support, while the flooring needs to ensure safety and optimal performance. Factories that create squash courts utilize advanced manufacturing techniques to produce the necessary components, ensuring that each court is built to last.

Choosing the Right Materials

One of the most critical aspects of building a squash court is selecting the appropriate materials. The walls are usually made from tempered glass or solid materials like concrete, which help maintain the durability and integrity of the court. Factories specialize in supplying these materials, ensuring they meet the structural requirements and provide a suitable playing environment.

The playing area typically features a hardwood floor, commonly maple, which balances hardness and elasticity. This flooring helps minimize the risk of injury while providing excellent ball rebound characteristics. Factories dedicated to flooring production leverage technology that enhances the durability and aesthetic appeal of the court, appealing to both players and facility owners.

The Role of Technology in Construction

Modern squash court factories utilize cutting-edge technology to streamline the construction process. CAD (Computer-Aided Design) software enables architects and engineers to create accurate blueprints and visualize the project before construction begins. This technology allows for modifications, ensuring the final design aligns with the clients’ specifications and regulatory standards.

Moreover, automation in factories helps to speed up the production of court components. Prefabrication of walls and flooring sections reduces on-site construction time, making the setup process more efficient. Factories arrange for precise measurements, which are critical for the overall quality and performance of the squash court.

Customization and Aesthetics

Each squash court can be tailored to meet individual preferences, whether it's the color of the walls or the finish of the flooring. Factories often offer customizable options, allowing clients to infuse their identity into the court design. This customization extends to sponsorship opportunities and branding elements, making the facility attractive to local squash communities and professional players alike.

In addition to functionality, aesthetics play a significant role in the appeal of a squash court. Factories can provide various finishes and surface treatments that enhance the court's visual appeal while ensuring it retains its performance characteristics.

Compliance with Regulations

Constructing a squash court also involves adherence to regulations set forth by governing bodies like the World Squash Federation (WSF). Factories that specialize in squash court construction have a deep understanding of these standards. They ensure that each aspect, from dimensions to wall materials, complies with the regulations, helping to avoid potential issues during inspections or competitions.

Conclusion

Building a squash court is a multifaceted endeavor that relies heavily on the expertise of specialized factories. From selecting the right materials to implementing advanced technology, these manufacturers play a crucial role in ensuring that each court meets performance and safety standards. As the popularity of squash continues to grow, the demand for high-quality courts has never been higher. By understanding the intricacies involved in constructing a squash court, those interested in promoting the sport can appreciate the craftsmanship and thought that goes into creating a world-class playing facility.

In essence, whether you are a player, a facility manager, or a sports enthusiast, recognizing the importance of quality construction and the role of specialized factories is vital in supporting the sport of squash.

AI-Designed Paddle Racquet | GPT-4 Turbo Tech

Premium Paddle Racquet | AI-Optimized Design

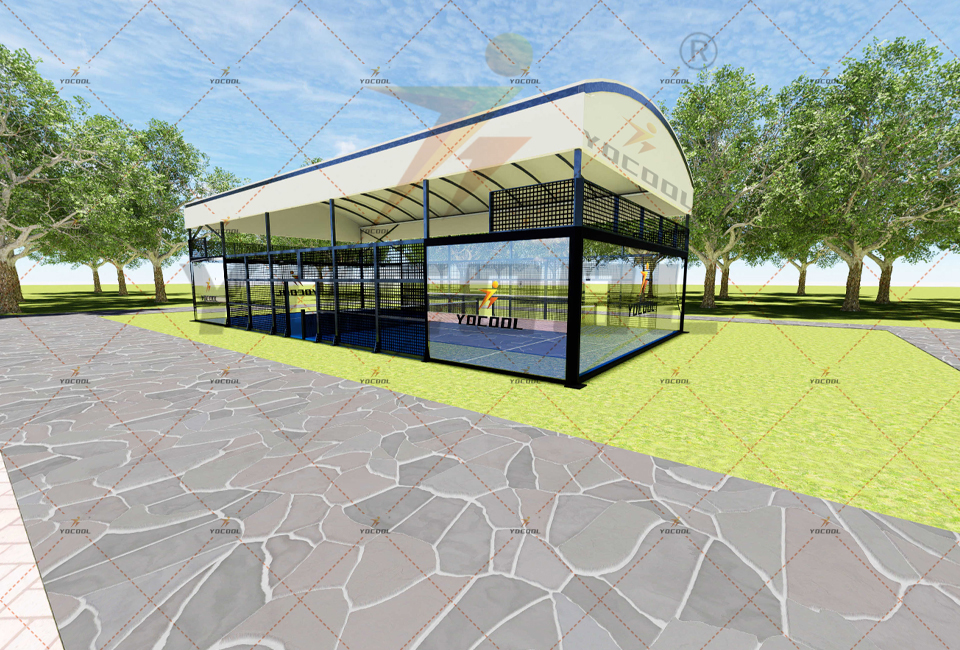

Smart Padel Courts with GPT-4 Turbo AI

AI-Powered Paddle Racquet w/ GPT-4-Turbo Optimized

China Pro Ping Pong Paddle | Premium Spin Control

Premium AI-Enhanced Padel Court | GPT-4 Turbo Design