Investing in a padel tennis court can be a significant venture, especially when considering the cost implications associated with setting up a facility through a specialized factory. Understanding the comprehensive breakdown of expenses and processes involved can empower individuals and businesses to make informed decisions about their investment.

The costs of constructing a padel tennis court through a factory setting vary widely, driven by factors such as location, materials, and design specifics. The first consideration is land acquisition or lease costs, which fluctuate depending on the region's real estate market. In urban areas, these costs are typically higher, influencing the overall budget significantly.

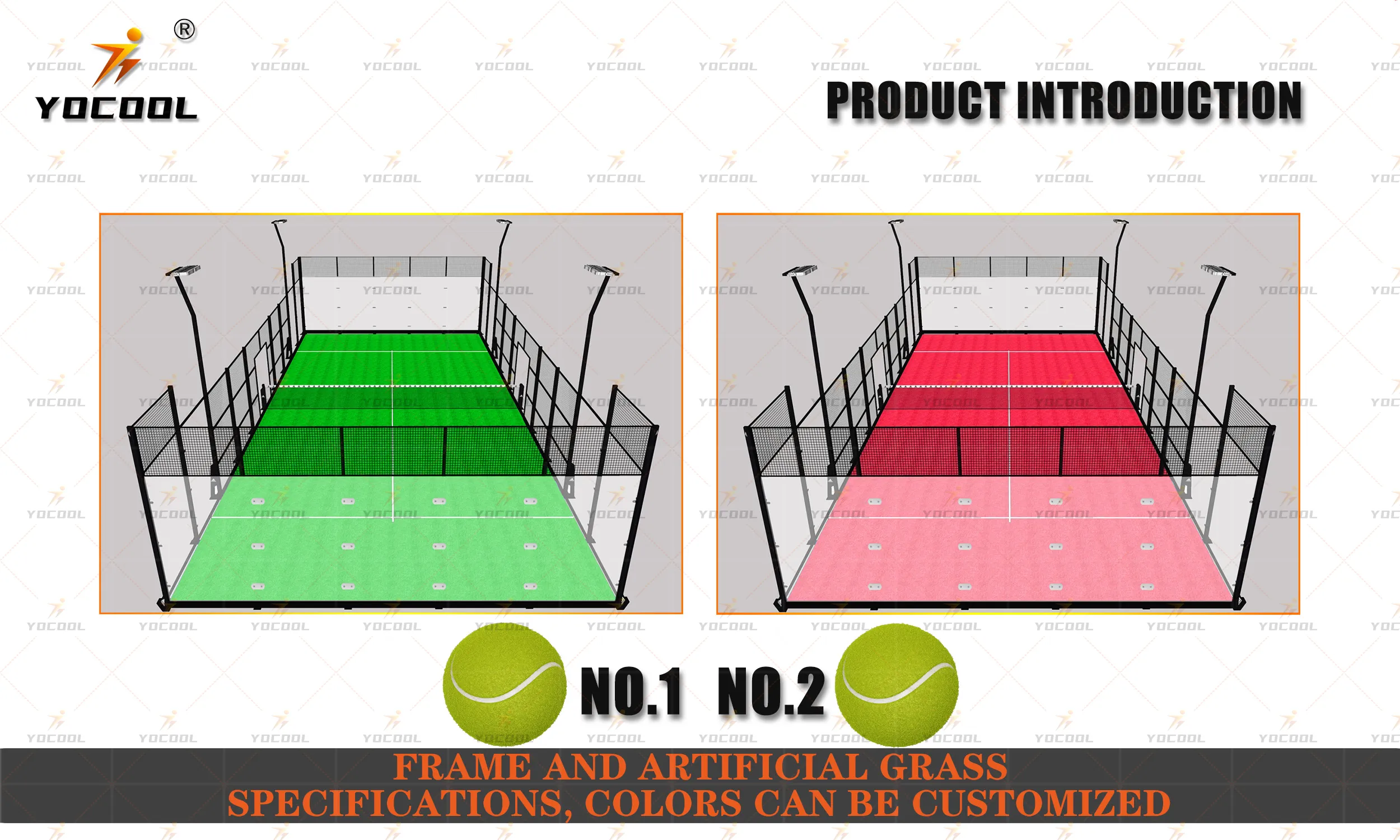

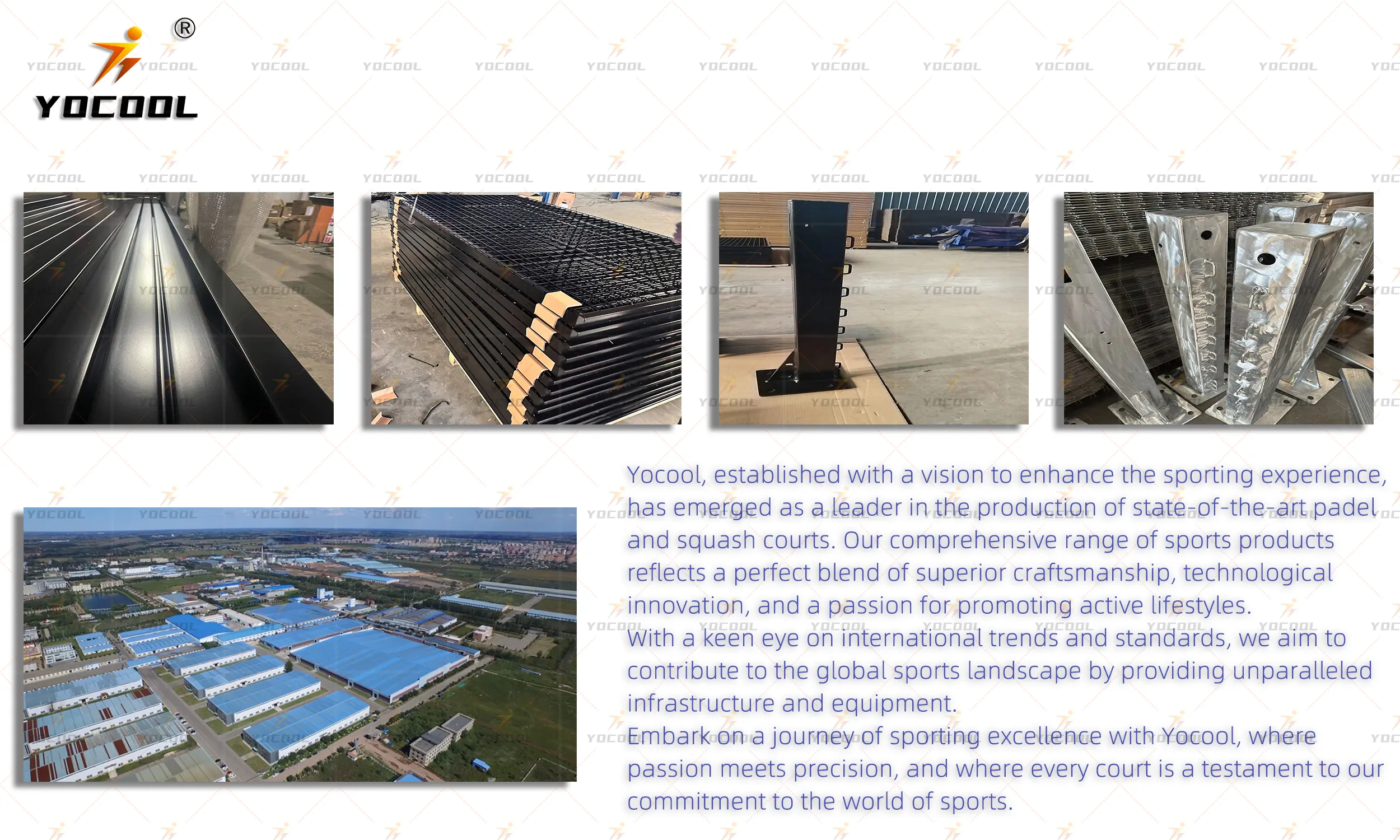

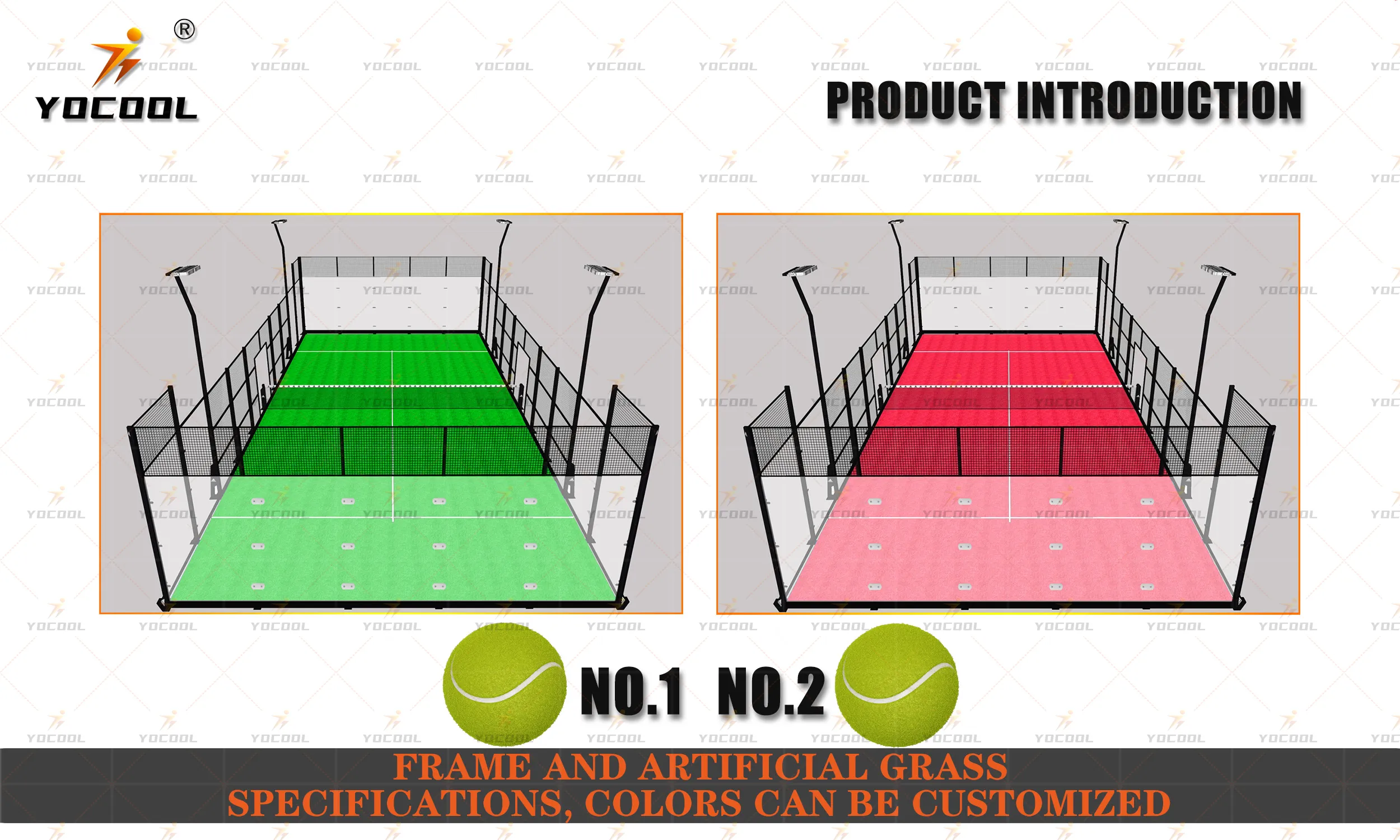

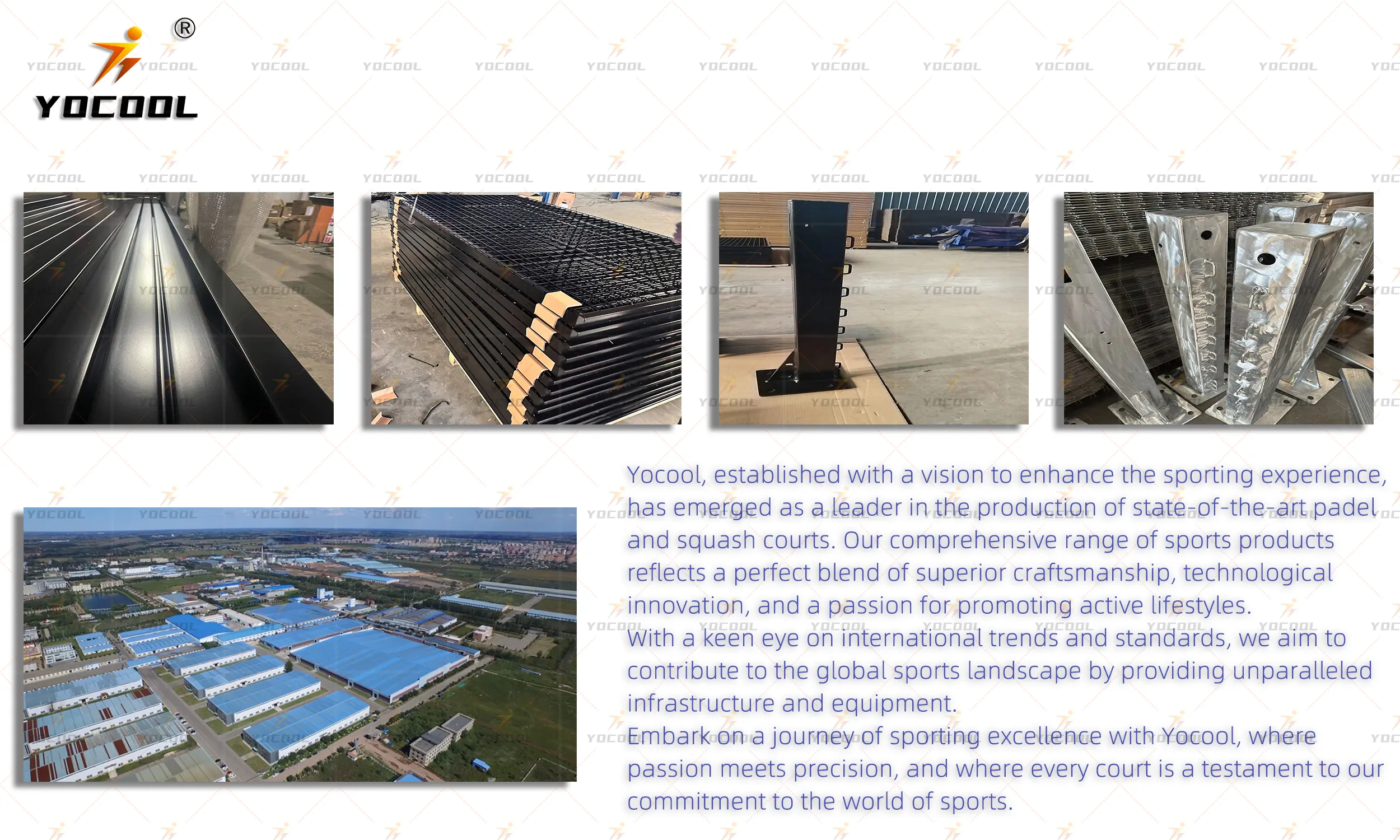

The selection of materials plays a critical role in both cost and the quality of the padel court. Opting for high-quality, durable materials might entail a higher upfront cost but promises long-term savings on maintenance and repairs. Synthetic turf, glass walls, and robust metal structures are commonplace in modern padel courts. Factories specializing in court construction often have access to premium materials at bulk prices, offering some cost benefits.

Design and engineering requirements are other essential cost contributors. Expertly crafted designs ensure optimal playability, safety, and aesthetic appeal. Factories usually employ skilled engineers and designers who understand the nuances of court specifications, from surface texture to enclosure dimensions. Their expertise guarantees that the final product adheres to international standards, bolstering the facility's credibility and attractiveness to players.

Logistics is another significant component, encompassing the transportation and assembly of court materials. Depending on the factory's location relative to the installation site, transportation costs can vary. Many factories offer package deals that include transportation, potentially offsetting high shipping expenses. Efficient logistics management is crucial to maintaining the project's budget and timeline.

padel tennis court cost factory

Installation is a labor-intensive element requiring skilled technicians familiar with padel court specifics. Factories often provide or recommend installation crews adept at assembling courts to exact specifications. The efficiency of this process directly impacts both cost and timeframes. A rapid, accurate installation translates into lower labor costs and a quicker return on investment as the court becomes operational sooner.

Maintenance costs must also be factored into the long-term financial plan. While factories engineer courts for durability, regular upkeep is essential to preserve quality and safety. Some factories offer maintenance packages or training for local staff, ensuring the court remains in top condition and reducing the likelihood of costly repairs.

When assessing the financials of constructing a padel tennis court via a factory, potential owners should also consider economic incentives. Some regions offer tax breaks or grants for developments that promote sporting activities, which can alleviate some of the financial burdens.

In conclusion, the cost of constructing a padel tennis court through a factory involves multiple components that require thorough evaluation. By leveraging factory expertise in materials, design, logistics, and installation, investors can optimize their expenditure and ensure that their facility meets high standards of quality and performance. Understanding these aspects contributes to making a well-informed investment that is economically viable and sustainable over the long term.