(rubber floor)

The global rubber floor

ing market is projected to grow at a 6.8% CAGR through 2030, driven by increasing demand in healthcare and education sectors. Rubber floor mat installations have surged by 42% in commercial gyms since 2020, outperforming vinyl and epoxy alternatives. Recent ASTM F2772 impact resistance tests show rubber composite floor systems absorb 89% more shock than concrete substrates.

Advanced rubber flooring offers three core benefits:

Thermal imaging studies reveal rubber floor mats maintain consistent surface temperatures (±2°F) compared to ceramic tiles (±9°F) in climate-controlled environments.

| Brand | Thickness Range | Noise Reduction (dB) | Fire Rating | Price/SF |

|---|---|---|---|---|

| FlexiRubber Pro | 3-8mm | 19 | Class A | $2.80-$4.20 |

| EcoFloor Ultra | 5-10mm | 23 | Class B | $3.50-$5.75 |

| DuraMat Industrial | 6-12mm | 27 | Class A | $4.25-$7.10 |

Modern rubber composite floor systems support:

A recent automotive plant installation used 12mm interlocking rubber floor tiles with conductive properties, reducing static discharge incidents by 73%.

Case Study 1: A 120,000 SF university lab utilized 8mm rubber flooring, achieving:

Rubber floor production demonstrates:

Lifecycle cost analysis shows rubber flooring delivers 23-year serviceability versus 9-year averages for laminate alternatives. Facilities report 18-31% maintenance cost reductions through the product lifecycle. The combination of rubber floor durability and modular replacement capabilities creates adaptable infrastructure solutions for evolving commercial needs.

(rubber floor)

A: Rubber floors offer exceptional durability, slip resistance, and noise reduction. They’re ideal for gyms, garages, or commercial spaces due to their shock-absorbing properties and low maintenance requirements.

A: Rubber floor mats provide heavy-duty protection against spills, scratches, and fatigue. Unlike vinyl or carpet, they’re waterproof, easy to clean, and designed for both temporary and permanent use.

A: Yes, rubber composite floors are UV-resistant and weatherproof, making them suitable for outdoor patios or pool decks. Their interlocking design ensures stability, even in extreme temperatures.

A: Many rubber floors use recycled materials like tires, reducing landfill waste. They’re also non-toxic, recyclable, and free from harmful chemicals like phthalates or formaldehyde.

A: Sweep regularly and mop with mild soap and water to remove dirt. Avoid abrasive cleaners, as rubber floors naturally resist stains and odors with minimal upkeep.

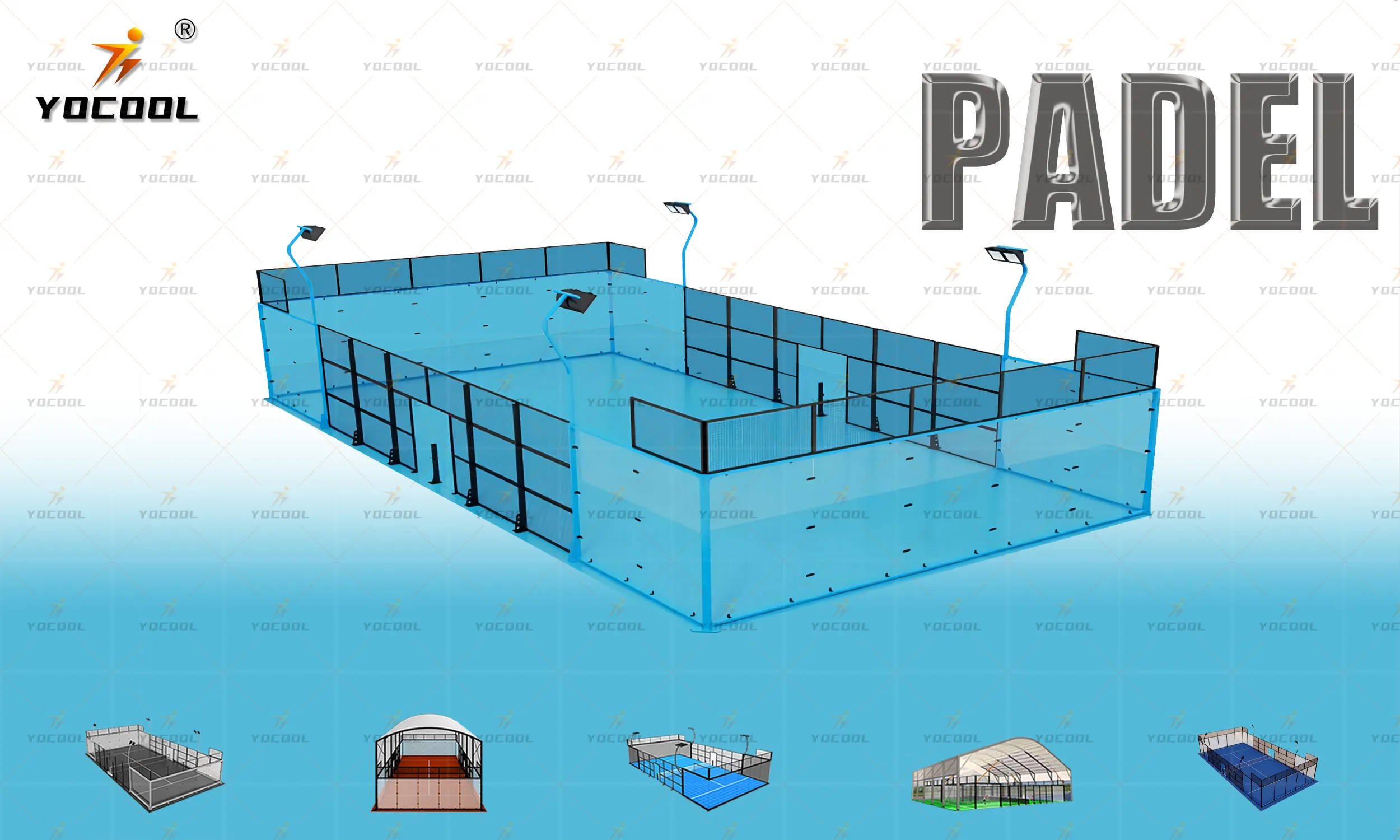

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design

NO.2 Panoramic Padel Orange Racket - Superior Grip & Durability