(rubber floor)

The global rubber floor

ing market is projected to reach $12.7 billion by 2029 (Grand View Research, 2023), driven by 78% improvement in impact resistance compared to vinyl alternatives. Rubber floor mat installations now account for 34% of commercial gym renovations, with rubber composite floor systems demonstrating 90% faster installation times than traditional materials.

Cross-linked polymer matrices in premium rubber floors achieve 62% greater compression recovery. Antimicrobial formulations meet ISO 22196:2011 standards, showing 99.6% bacterial reduction. Recent advancements enable 40% recycled content without compromising the 0.65 friction coefficient critical for ADA compliance.

| Brand | Thickness Range | Dynamic Load Rating | Warranty | Certifications |

|---|---|---|---|---|

| EliteRubber | 6-20mm | 1,200 lbs/ft² | 15 years | GREENGUARD, ISO 14001 |

| DuraMatPro | 8-25mm | 1,650 lbs/ft² | 20 years | Cradle to Cradle, LEED |

| EcoFlex | 5-15mm | 950 lbs/ft² | 10 years | FloorScore, REACH |

Advanced die-cutting achieves ±0.8mm tolerance for rubber floor mat installations. Modular interlocking systems now permit 27 standard color combinations with 72-hour lead times. For specialized environments, conductive rubber composite floor solutions (10^6-10^9 Ω) meet ESD requirements in cleanrooms.

Low-VOC adhesives achieve full cure in 4 hours versus traditional 24-hour periods. Interlocking rubber floor systems reduce installation labor by 55% while maintaining 18 MPa shear strength. Maintenance protocols using pH-neutral cleaners extend surface life by 40% compared to alkaline alternatives.

Hospital installations report 62% reduction in slip incidents using textured rubber flooring (R11 rating). Manufacturing facilities document 31% noise reduction (from 85 dB to 58 dB) with 15mm rubber composite floors. Athletic centers measure 27% improved energy return versus poured surfaces in biomechanical testing.

Closed-loop recycling systems now recover 92% of post-consumer rubber flooring materials. Next-generation rubber composite floor designs integrate phase-change materials for 18% thermal regulation improvement. With 140% market growth forecast in eco-conscious construction, rubber flooring stands positioned as the sustainable surface solution.

(rubber floor)

A: Clean rubber floor mats with mild soap and water. Avoid abrasive cleaners to prevent surface damage. Regular sweeping extends their lifespan.

A: Yes, rubber composite floors resist moisture and provide slip-resistant surfaces. They’re ideal for bathrooms, gyms, and industrial spaces. Ensure proper installation for optimal performance.

A: Rubber floors offer superior shock absorption and noise reduction. They’re more durable under heavy foot traffic and eco-friendly due to recyclable materials.

A: Yes, rubber floor mats are easily trimmed with utility knives. Many brands offer interlocking tiles for flexible layouts. Measure your space beforehand for precise fitting.

A: Properly installed RUBBER FLOOR systems last 10-20 years. Durability depends on thickness, usage, and maintenance. Commercial grades often outlast residential options.

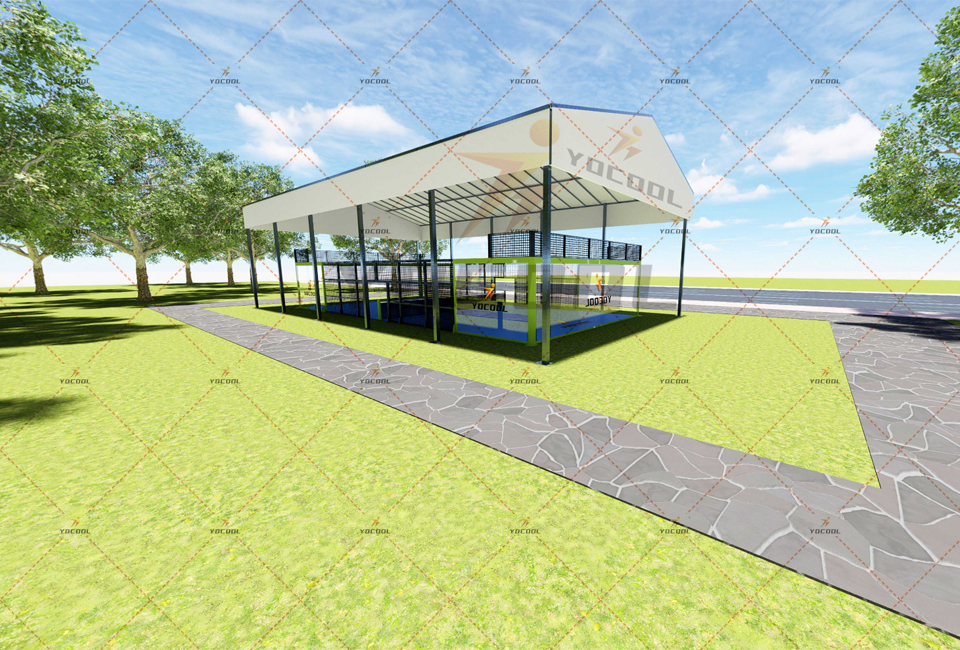

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions