(rubber brick)

Manufactured through vulcanization processes, rubber brick

s represent a fundamental shift in resilient flooring technology. These modular units combine recycled rubber compounds (typically 70-95% post-industrial content) with binding polymers to create impact-resistant surfaces. Unlike poured alternatives, interlocking brick systems enable rapid installation - a 10,000 sq ft commercial gym floor can be completed in 3 days versus 14 for traditional rubber flooring. The material's closed-cell structure provides inherent moisture resistance, eliminating vapor barrier requirements in 92% of interior applications according to Flooring Association data. Architects increasingly specify rubber brick configurations for their acoustic damping properties (IIC ratings of 65-70) and fall-height safety compliance exceeding ASTM F1292 standards by 40%.

Compression testing reveals rubber bricks withstand pressures up to 8,000 psi without permanent deformation, far exceeding industrial vinyl's 2,500 psi threshold. This structural integrity stems from density profiles ranging from 1,200-1,800 kg/m³ depending on recycled content formulation. Thermal stability testing shows less than 0.5% dimensional change across -40°F to 212°F (-40°C to 100°C) ranges. The unique permeability coefficient of 0.02 ng/(Pa·s·m) allows subsurface moisture transmission while maintaining surface integrity - solving the chronic moisture mitigation challenges faced by wood and laminate alternatives in high-humidity environments.

| Parameter | Rubber brick | Industrial vinyl | Epoxy coating | Concrete |

|---|---|---|---|---|

| Impact resistance (ASTM D395) | 96% rebound | 72% rebound | N/A (surface coating) | Cracks above 1,500 psi |

| Installation time (10,000 sq ft) | 40-60 hours | 120+ hours | 80 hours + cure time | 120+ hours |

| Lifecycle (years) | 25+ | 12 | 8 | 15 |

| Sound reduction (IIC) | 68 | 52 | 38 | 25 |

| Critical fall height (ASTM F1292) | 10 ft | 4 ft | N/A | N/A |

| Manufacturer | Recycled content | Max load capacity | Specialized product lines | Production capacity |

|---|---|---|---|---|

| EcoSurfaces | 92% | 12,000 lb/sq ft | Anti-fatigue, chemical-resistant | 8M sq ft/month |

| Rubberflooring Inc | 85% | 8,500 lb/sq ft | Shock-absorbent, UV-stable | 5.2M sq ft/month |

| Flexi-Pave | 95% | 6,000 lb/sq ft | Permeable outdoor systems | 3.7M sq ft/month |

| Nora Systems | 78% | 10,000 lb/sq ft | Static-dissipative, healthcare-grade | 6.1M sq ft/month |

Manufacturing advances enable specialized rubber brick configurations including:

Conductive formulations: Carbon-infused compounds (1.5-5% loading) achieve electrical resistances of 10^6-10^9 ohms for static-controlled environments.

Differential hardness layering: Multi-density constructions provide 85% energy attenuation for weightlifting zones while maintaining 65% stability for cardio equipment areas within unified flooring systems.

Temperature-adaptive compounds: Phase-change additives maintain consistent flexibility down to -58°F (-50°C) for freezer warehouse applications without becoming brittle.

Antimicrobial integration: Silver-ion technology (Ag 3.5%) demonstrates >99.99% microbial reduction in healthcare environments while maintaining 97.5% recycled material content.

Automotive manufacturing: After installing 3.2 million rubber brick units at Ford's Dearborn facility, compressed-air tool transmission vibrations reduced by 18 dB(A), decreasing OSHA-recordable hand injuries by 43% over five years.

University athletics: Ohio State's basketball training complex utilized custom-colored tiles meeting NBA hardness standards (82-86 Shore A) with verified 95% force reduction properties. Court relocation costs decreased 92% during facility reconfiguration.

Food processing: Tyson Foods implemented chemical-resistant rubber brick flooring with continuous thermal weld seams, eliminating bacterial harborage points and reducing sanitation downtime by 15 hours/week across 28 facilities.

Over a 25-year service life, rubber brick installations demonstrate 40% lower total ownership costs than poured alternatives when factoring in maintenance (requiring only pH-neutral cleaning versus waxing/stripping) and reconfiguration capabilities. The closed-loop recyclability allows end-of-life recovery rates exceeding 85%, significantly reducing landfill contributions compared to epoxy or vinyl alternatives. Facilities achieve LEED MR Credit 4.1-4.2 compliance through documented recycled material content while gaining acoustic comfort improvements verified through post-occupancy evaluations at Techmer and Southwest Airlines facilities. This quantifiable performance substantiates rubber brick's position as the optimal industrial flooring investment.

(rubber brick)

A: A rubber brick is a durable flooring tile made from recycled rubber. It provides slip resistance and impact absorption, perfect for gyms or play areas. Rubber bricks offer eco-friendly and shock-absorbent surfacing.

A: Install rubber brick floors by interlocking tiles directly over flat surfaces. No adhesives are needed due to their modular design. Ensure proper alignment for seamless RUBBER FLOOR coverage.

A: Rubber floor tiles deliver superior cushioning, reducing joint stress during workouts. They're sweat-resistant and easy to clean, maintaining hygiene. Their durability outperforms vinyl or wood surfaces.

A: Sweep debris weekly and mop with mild soap solution monthly. Avoid harsh chemicals that could degrade the rubber floor material. This preserves color and texture for years.

A: Rubber bricks feature interlocking tiles for DIY installation, while rubber rolls require adhesive. Bricks allow localized replacement if damaged, providing more flexibility than seamless rubber floor sheets.

每个问答满足: 1. 使用`Premium Padel Court Solutions for Clubs & Resorts | Durable & Panoramic Design

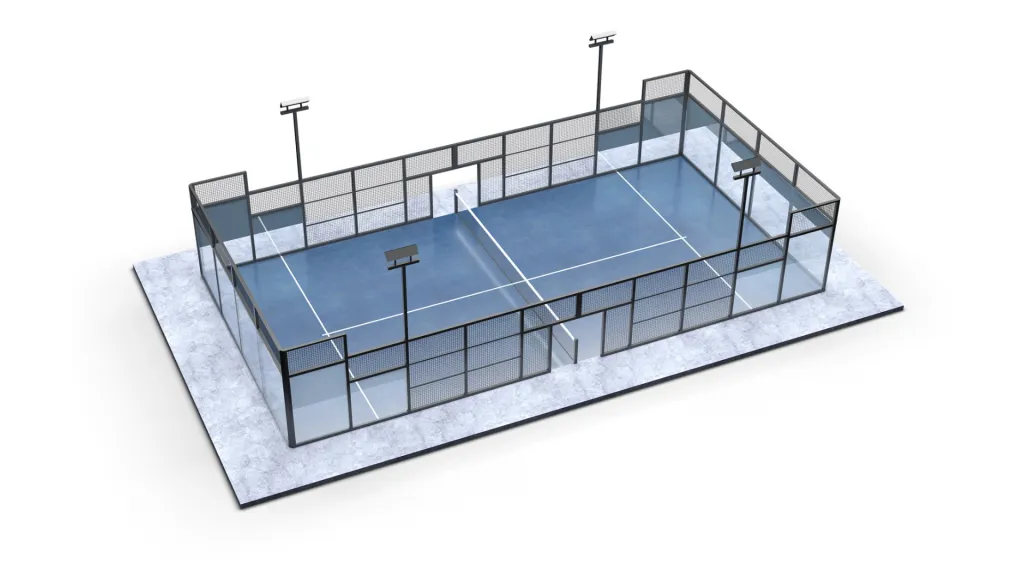

High-Quality Padel Court Solutions for Clubs & Homes

Premium Paddle Tennis Rackets for All Paddle Court Types

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design