The Evolution of Squash Court Factories Crafting Excellence in Sport

Squash, a sport characterized by its intense rallies and dynamic gameplay, has been gaining popularity worldwide. As enthusiasts flock to courts, the demand for high-quality squash facilities continues to rise. This has led to the emergence of specialized squash court factories, which focus on designing and manufacturing state-of-the-art courts that enhance the playing experience. This article explores the significance of squash court factories, their role in the sport's evolution, and the various elements that contribute to the development of exceptional squash courts.

The Importance of Squash Court Factories

Squash court factories play a pivotal role in the overall growth of the sport. By producing well-constructed courts that meet international standards, these factories ensure that players have access to top-notch facilities. Whether it’s for professional tournaments or local clubs, the quality of the court directly impacts player performance and satisfaction. Moreover, the presence of high-quality courts encourages more players to take up the sport, leading to a broader fan base and increased participation at grassroots levels.

Key Features of Squash Courts

To understand what makes a great squash court, it’s essential to delve into the specific features and materials involved in their construction. A standard squash court typically measures 9.75 meters wide, 6.4 meters high, and 4.57 meters long, with specific requirements for wall construction, flooring, and ventilation.

Wall Materials and Design

The walls of a squash court are critical to gameplay. They are usually made of glass, concrete, or a combination of both. The front wall must be particularly sturdy to endure the impact of the ball. Glass walls, becoming increasingly popular, allow spectators to view the action, enhancing the viewing experience while maintaining the necessary structural integrity. Manufacturers must ensure that the glass used is specifically tempered to prevent shattering upon impact, thereby enhancing player safety.

Flooring Solutions

The choice of flooring is another crucial aspect of squash court construction. The floor must provide adequate grip and cushioning to reduce the risk of injuries. Typically, hardwood floors are favored for their durability and resilience, while specialized synthetic surfaces are designed for superior shock absorption and ball bounce. Many squash court factories utilize advanced technology to create flooring that meets the precise requirements for competitive play.

Lighting and Ventilation

Proper lighting and ventilation systems are vital for any squash court. In many cases, LED lighting is preferred for its energy efficiency and ability to create a bright, even playing surface. Additionally, ventilation systems are designed to maintain air quality and temperature, ensuring that players can enjoy a comfortable environment during intense matches. Modern factories invest in research and development to create innovative solutions that address common issues related to heat and humidity in indoor sports facilities.

The Role of Technology

As technology continues to evolve, squash court factories are integrating innovative solutions into their designs. This includes automated systems for monitoring air quality, temperature control, and even advanced lighting that can adjust in intensity based on the time of day or the number of players on the court. Additionally, digital platforms for booking and managing court availability have made it easier for players to schedule their games, further enhancing the user experience.

Sustainability in Court Construction

Another emerging trend within squash court factories is the emphasis on sustainability. As global awareness of environmental issues increases, more manufacturers are striving to use eco-friendly materials and processes in their court construction. This includes sourcing sustainable wood for flooring, utilizing low-emission paints, and implementing energy-efficient systems. By adopting such practices, squash court factories not only reduce their carbon footprint but also appeal to environmentally conscious consumers.

Conclusion

In conclusion, the significance of squash court factories in the evolution of the sport cannot be overstated. By focusing on high-quality materials, innovative designs, and sustainable practices, these factories are helping to elevate the standard of squash facilities around the globe. As more players take to the courts, the continued advancement in court construction and design promises to enhance the experience for both players and fans alike, fostering a vibrant and growing squash community. The future of squash is bright, and it begins in the factories that craft the courts on which legends are made.

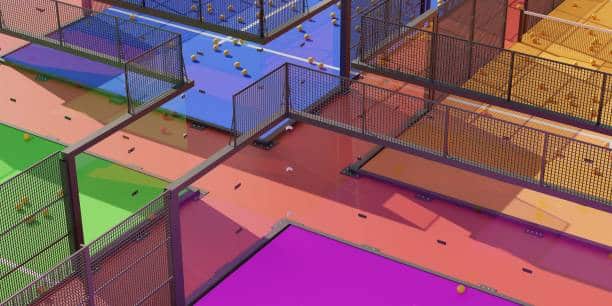

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions