Understanding Squash Balls Types and Manufacturing Processes

Squash, a fast-paced indoor racquet sport, has gained immense popularity across the globe. Central to this sport are the squash balls, which are crafted using specific materials and processes to ensure optimal performance. In this article, we will delve into the various types of squash balls and the factories that produce them, exploring how these elements contribute to the game.

Types of Squash Balls

Squash balls are classified primarily by their bounce, speed, and intended use. The major categories include

1. Single Yellow Dot Ball This is the official ball for professional players. It has the lowest bounce and is designed for advanced players who have a strong playing skill. It is made of a rubber compound that allows it to maintain its consistency while providing a controlled playing experience.

2. Double Yellow Dot Ball Slightly faster than the single yellow dot ball, it is used in most competitive matches and is suitable for intermediate to advanced players. It has a slightly different internal structure to aid its performance, allowing for a balance between speed and control.

3. Red Dot Ball This ball is designed for club players, providing a higher bounce and a more forgiving play style. It is typically used by beginners and junior players who are still developing their skills.

4. Blue Dot Ball The blue dot ball is regarded as the highest-bouncing squash ball and is the best choice for beginners and younger players. Its composition allows for maximum elasticity, catering to those who are still mastering their techniques.

Each type of ball is engineered to cater to different skill levels and playing styles, ensuring that players can choose one that best suits their needs.

The Manufacturing Process

The production of squash balls involves meticulous craftsmanship, utilizing both technology and traditional methods. Here is a simplified overview of how squash balls are manufactured

1. Material Selection The primary material used for squash balls is a specific type of rubber that provides the desired bounce and durability. Manufacturers often source their rubber from reputable suppliers to ensure high quality.

2. Molding The rubber is heated and put into molds to form the initial shape of the ball. This molding process is crucial as it dictates the ball's size and surface characteristics.

3. Testing and Quality Control Once the balls are shaped, they undergo rigorous testing to ensure they meet industry standards. This includes checking their bounce height, durability, and overall consistency. Quality control teams also inspect the balls for any defects or irregularities.

4. Final Touches After passing the quality tests, the balls are covered with a thin layer of specialized cloth that aids in providing grip and enhancing playability. The cloth is often treated to make it more resistant to wear and tear.

5. Packaging Finally, the finished squash balls are packaged effectively to be distributed to sporting goods stores and direct to customers. Packaging is essential for maintaining the integrity of the balls during transportation.

Leading Factories

Several factories worldwide specialize in manufacturing squash balls, each known for their unique quality and design philosophy. Some of the most prominent names in the industry have established reputations due to their extensive experience and adherence to high production standards. These factories often invest in modern technologies and innovative processes to enhance the performance characteristics of their products.

In conclusion, the world of squash balls is both fascinating and intricate, with a variety of types tailored to meet the demands of different players. The manufacturing processes behind these balls are carefully designed to ensure quality and performance. As more players take up squash, the continued advancements in both ball type and technology promise to enhance the game, making it more exciting for players at all levels. Whether you are a beginner discovering the sport or an experienced player perfecting your skills, understanding the nuances of squash balls can greatly enrich your playing experience.

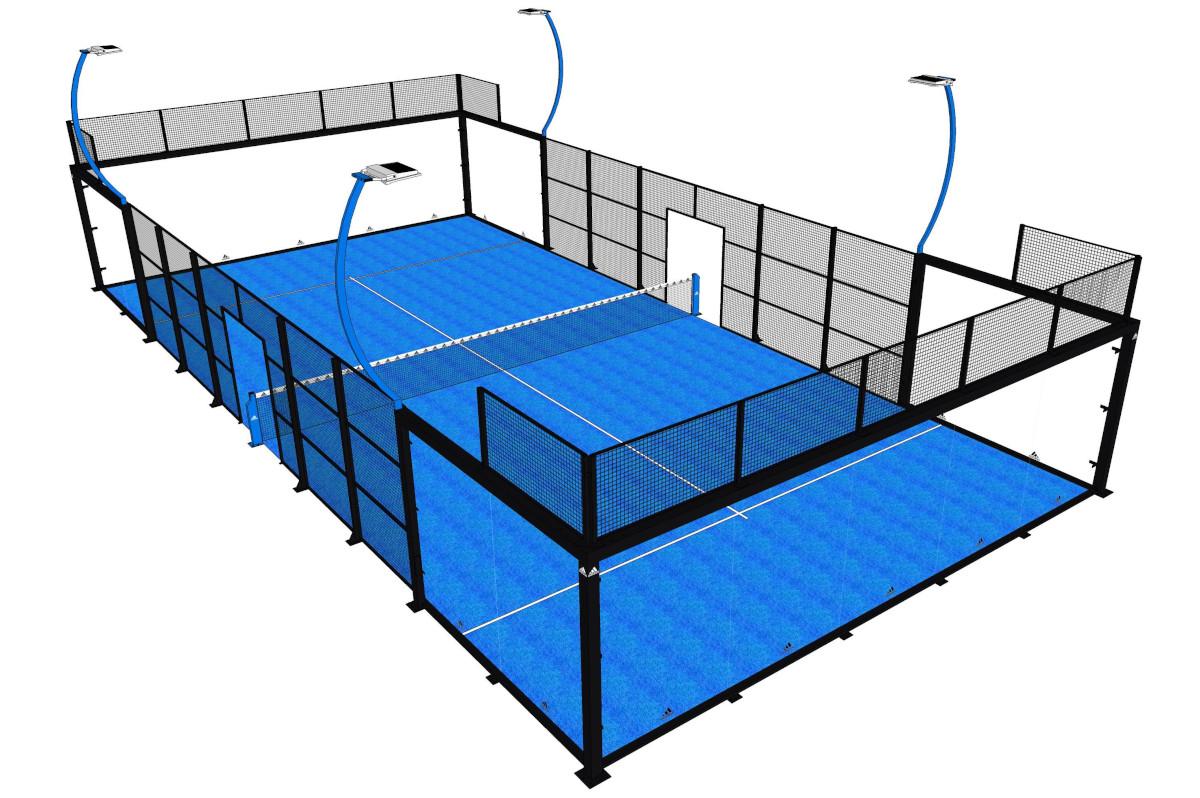

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions