The Rising Demand for High-Quality Squash Ball Courts An Insight into Factory Production

In recent years, the popularity of squash as a sport has seen a significant resurgence. This rise is not merely confined to the courts but extends to an increasing demand for high-quality squash facilities worldwide. As more players, from amateurs to professionals, take to the courts, the need for well-constructed squash ball courts has never been more pronounced. Consequently, squash ball court factories are stepping up to meet this growing demand by innovating and enhancing their production processes.

Squash courts are unique in their design and construction requirements. A standard squash court measures 9.75 meters wide and 4.57 meters high, with specific materials required to ensure optimal playing conditions. Manufacturers of squash courts focus on utilizing high-grade materials like engineered wood, glass, and other composites to create courts that not only look good but also provide excellent performance characteristics. Factories now employ advanced technologies for cutting, assembling, and finishing these materials to meet precise specifications.

One of the critical factors to consider when constructing squash courts is acoustic performance. The sound generated during play can significantly impact the experience of both players and spectators. Advanced factories are using noise-reducing materials and installations in their court designs to minimize echo and sound distortion. This feature is particularly crucial in areas where multiple courts are located close to one another.

Moreover, the flooring of squash courts plays a vital role in both player performance and injury prevention. Factories producing squash courts invest in specialized flooring systems that provide adequate grip, shock absorption, and support. These systems often use proprietary technology to combine resilience and durability, ensuring that courts can withstand the wear and tear of daily play while minimizing the risk of injuries.

In addition to the technical aspects of court production, environmental sustainability has emerged as a significant concern. Many squash ball court factories are adopting eco-friendly practices, such as using sustainably sourced materials and implementing energy-efficient production methods. This commitment not only speaks to the current climate crisis but also attracts environmentally conscious consumers and clubs looking to build a responsible image.

Customization is another trend that has gained traction within the squash court manufacturing industry. Many factories now offer customized court designs tailored to specific client needs, whether that be unique branding for a private club or specific modifications for community health centers. This ability to adapt and innovate according to the client’s vision is crucial in standing out in a competitive market.

Internationally, the competitive landscape of squash court manufacturing is also evolving. Many factories are forming global partnerships to enhance the exchange of technology and best practices. These collaborations can lead to improved designs and superior construction techniques that benefit the sport as a whole.

In conclusion, the increasing interest in squash has propelled the growth of squash ball court factories, which are now at the forefront of innovation in sports facility construction. By focusing on quality materials, acoustic performance, safety, sustainability, and customization, these factories are equipped to meet the rising demand for squash courts. As the sport continues to flourish, the role of these manufacturers will be crucial in shaping the future of squash, making it accessible and enjoyable for players around the world.

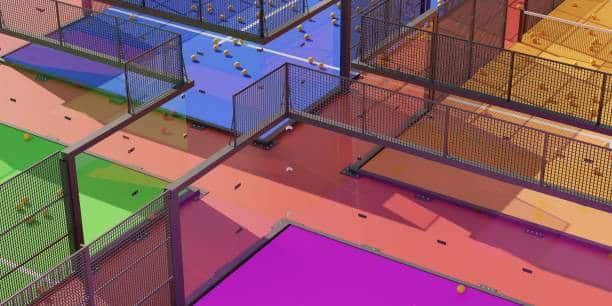

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions