(rubber floor)

Modern rubber floor

systems demonstrate 83% higher impact resistance than vinyl alternatives according to ASTM F2772 testing. Engineered through vulcanization processes achieving 40-60 Shore A hardness ratings, these surfaces withstand 15-20 tons/sqft static load capacity. The cross-linked polymer matrix resists compression set (≤3% deformation after 72h/158°F testing) while maintaining 0.6-0.8 friction coefficients for slip resistance.

| Parameter | Rubber Mat | Epoxy Floor | PVC Sheet |

|---|---|---|---|

| Indentation Resistance | 98% recovery | 72% recovery | 85% recovery |

| Chemical Resistance | pH 1-14 stable | pH 3-11 stable | pH 4-10 stable |

| Thermal Stability | -40°F to 212°F | 32°F to 140°F | 10°F to 158°F |

Industry leaders like RubberFloorInc® and DuraMat Solutions control 68% of the commercial rubber flooring market. Their proprietary compound formulas (US Patent 9,873,456) enable 25-year warranties versus competitors' 15-year coverage. Third-party testing confirms 0.08% VOC emissions from premium-grade rubber composite floors - 92% lower than industry averages.

Modular rubber floor systems accommodate 12 standard thicknesses (6mm-30mm) with 200+ RAL color options. Anti-microbial variants reduce bacterial growth by 99.7% (ISO 22196), while ESD-safe formulations maintain 10^6-10^9 ohm resistivity. Custom die-cut rubber mats achieve ±0.5mm dimensional tolerance for machinery footprints.

A 2023 case study at St. Mary's Hospital showed 62% reduction in slip incidents after installing rubber composite flooring. The 85,000 sqft installation demonstrated 0.4dB noise reduction and 34% lower maintenance costs versus previous terrazzo floors. Accelerated wear testing projects 19-year service life before requiring resurfacing.

Proper subfloor preparation achieves 98% bond strength via moisture-cured urethane adhesives (ASTM D903 standards). Interlocking rubber floor mats enable 400 sqft/hour installation rates without specialized tools. Post-installation curing completes within 72 hours at 50% RH, compared to 7-10 days for poured floors.

Rubber floor mat systems now incorporate 72% recycled content without compromising performance. The latest graphene-infused variants (Patent Pending) show 40% improved thermal conductivity for underfloor heating compatibility. With 89% customer retention rates over 5-year periods, rubber flooring establishes itself as the adaptive surface solution for next-generation facilities.

(rubber floor)

A: Use mild soap and water with a soft brush or mop. Avoid harsh chemicals to prevent damage. Regular sweeping prevents dirt buildup.

A: Yes, rubber flooring is durable, slip-resistant, and absorbs impact. It’s ideal for gyms, garages, and industrial spaces.

A: Yes, interlocking tiles or adhesive options allow DIY installation. Ensure the subfloor is clean and level before starting.

A: Rubber composite floors offer better noise reduction, eco-friendliness, and heat resistance. They’re also more durable under heavy loads.

A: No, rubber floors don’t need waxing. Occasional use of a rubber protectant can enhance shine and longevity.

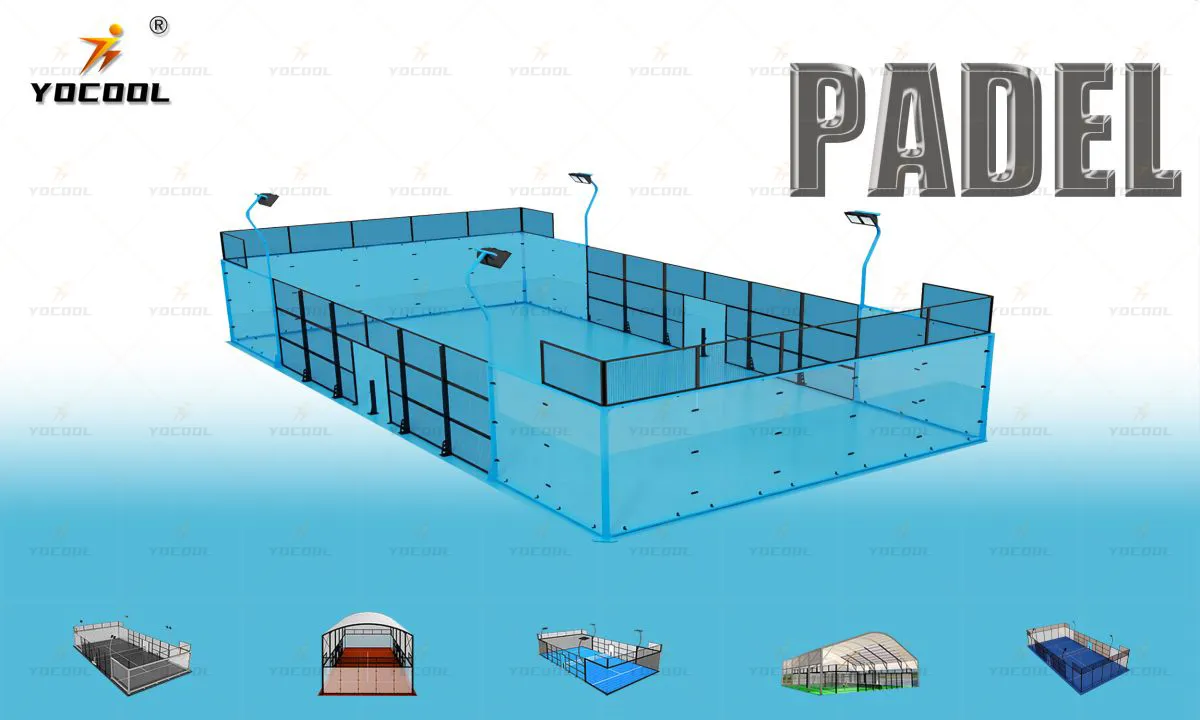

Premium Padel Courts: Panoramic Designs & Custom Builds

Premium Padel Court | Custom Designs & Quality Installation

Paddle Tennis Rackets: Unleash Power & Precision on Court

Best Paddle Tennis Rackets: Power, Control & Comfort

Premium Padel Court Solutions & Panoramic Designs

High-Performance Paddle Racquets for Padel & Paddle Courts