The Rise of Racquetball and Its Manufacturing Landscape

Racquetball is a unique and energetic sport that has seen a surge in popularity since its inception in the mid-20th century. Unlike many traditional racquet sports, which often rely on extensive outdoor facilities, racquetball is played indoors in a specially designed court, making it accessible in various climates and regions. This distinct characteristic has not only contributed to the sport's accessibility but has also fostered the growth of a dedicated manufacturing industry focused on creating high-quality racquetball equipment. In this article, we will explore the various facets of racquetball sport factories, their contributions to the sport, and the future of racquetball manufacturing.

Understanding Racquetball Equipment

At its core, racquetball is played with a few essential pieces of equipment a racquet, a ball, protective eyewear, and appropriate athletic wear. Each component plays a significant role in gameplay. The racquets, often made from lightweight composite materials, allow for quick maneuverability and powerful strokes. Balls designed specifically for racquetball are rubberized and come in various colors, ensuring players can easily track them during fast-paced rallies.

The manufacturing of these items is a meticulous process that combines technology and craftsmanship. Modern racquetball racquets, for example, go through advanced engineering processes that enhance their performance characteristics, such as grip, weight distribution, and balance. Manufacturers use computer-aided design (CAD) to create prototypes that are rigorously tested by professional players before mass production. This blend of technology and athlete input ensures that the final product meets the needs of end-users, providing them with the best possible tools for their game.

The Manufacturing Landscape

Racquetball sport factories vary in size and capacity, ranging from small, specialized workshops to large, industrial facilities. Some of the prominent brands in racquetball like Ektelon, Wilson, and HEAD have invested heavily in sophisticated production techniques that allow them to quickly adapt to market demands. These factories not only produce racquets and balls but also focus on accessories like gloves and bags that enhance the overall sports experience.

In recent years, many manufacturers have turned towards sustainable practices to minimize their environmental impact. This trend is becoming increasingly important as consumers are more conscious of the ecological footprint of their purchasing choices. Factories are adopting sustainable materials, reducing waste in production processes, and implementing recycling programs.

The Role of Innovation

Innovation is a crucial aspect of racquetball equipment manufacturing. With the continuous evolution of sports science, manufacturers are constantly looking for ways to incorporate new technology into their products. Features such as enhanced grip materials, improved shock absorption, and new aerodynamic designs are primary focuses in research and development. Factors like player feedback and performance analytics are vital in guiding these innovations.

Moreover, many brands partner with professional athletes to refine their products. Athlete endorsements not only drive sales but also serve as a feedback loop for companies to enhance their offerings based on real-world use. This collaboration has led to the development of signature racquets tailored to the playing style of top racquetball stars, creating a strong connection between the equipment and the players.

Challenges and Future Prospects

The racquetball manufacturing industry does face challenges, including competition from other sports and the need for constant innovation. Additionally, as the popularity of the sport fluctuates, manufacturers must remain agile and responsive to market trends. However, the outlook for racquetball appears promising as more individuals engage with the sport. Initiatives aimed at introducing racquetball in schools and community centers are gaining traction, potentially increasing the customer base.

As we look to the future, the integration of technology such as smart wearables and analytics into racquetball could offer new opportunities for manufacturers. These technologies can provide players with insights about their performance, helping them to improve their skills and keep them engaged with the sport.

Conclusion

In conclusion, racquetball sport factories play a significant role in the development and popularization of racquetball. Through innovative manufacturing processes, a commitment to sustainability, and collaboration with professional athletes, these factories continue to enhance the game experience for players of all levels. As the sport gains momentum, the future of racquetball manufacturing looks bright, promising continued growth and evolution in the years to come.

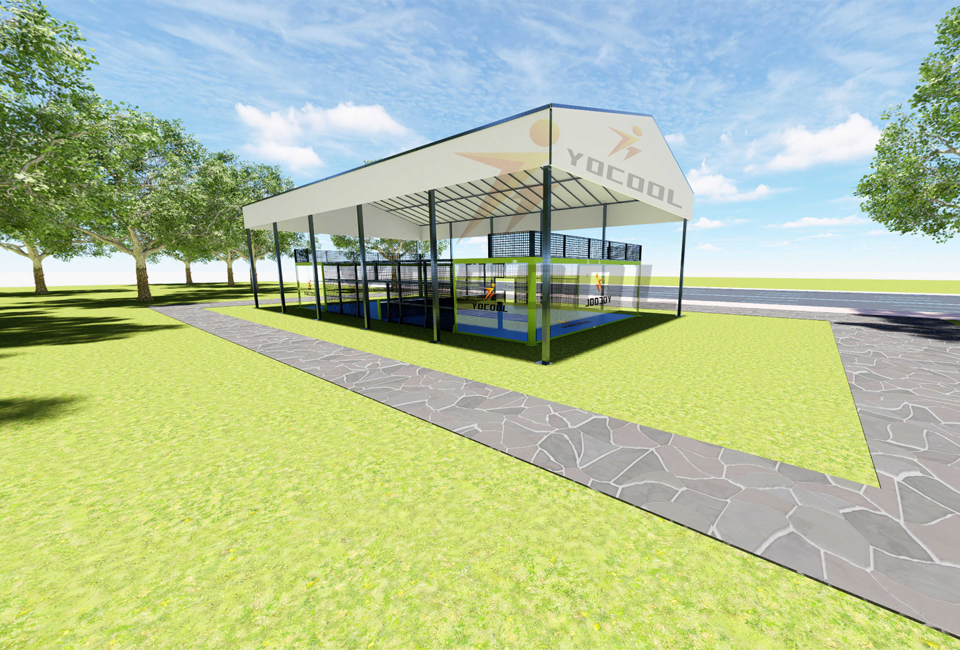

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions