The Intersection of Racquetball and Tennis Manufacturing A Comparative Analysis

Racquetball and tennis, while distinctly different sports, share a fascinating relationship through their common roots in racquet sports. Both have evolved into globally recognized games, each with a dedicated following and a diverse array of equipment tailored for various levels of play. This article delves into the manufacturing aspects of racquetball and tennis, exploring the similarities and differences between the production of equipment for these dynamic sports.

At the heart of both sports is the racquet—an essential tool that impacts performance significantly. Tennis racquets feature a larger head and longer handle, designed to hit a felt-covered ball over a net. In contrast, racquetball racquets are generally shorter and have a smaller head, optimized for striking a rubber ball within a walled court. The materials used in manufacturing these racquets have advanced significantly over the years, with innovations leading to lighter, more durable, and more responsive designs.

The tennis racquet market has seen a shift toward high-performance materials such as carbon fiber and graphite, which offer a blend of strength and lightness. Manufacturers like Wilson, Babolat, and Head invest heavily in research and development to push the boundaries of technology, creating racquets that enhance spin, control, and power. For instance, Babolat's Pure Drive series incorporates a unique frame design that allows for better aerodynamics and resilience, appealing particularly to intermediate and advanced level players.

Conversely, racquetball manufacturers such as Ektelon and Head tend to focus on different performance metrics, given the unique dynamics of the game. The racquets in racquetball are designed to provide quick maneuverability and forgiveness on off-center hits. With this in mind, many racquetball racquets feature a lighter construction and broader frames. The use of materials similar to those in tennis—e.g., composite designs including aluminum and lightweight plastics—facilitates rapid swings and swift gameplay.

When it comes to strings, both racquetball and tennis have developed sophisticated technologies geared towards enhancing play. Tennis strings have branched into multifilament, polyester, and natural gut varieties, each providing distinct benefits in terms of feel, spin, and durability. Manufacturers carefully consider which combinations of string materials will work best with their rackets, as tension and string type profoundly influence playability.

Racquetball strings, while less diverse than tennis strings, exhibit unique characteristics aimed at enhancing control and power

. As the sport requires rapid hand-eye coordination and quick reflexes, manufacturers like Ektelon utilize durable synthetic strings that can withstand repeated impact without losing tension—a critical aspect that directly affects game performance.Aside from racquets and strings, both sports also involve the production of various ancillary equipment. Tennis balls, for example, must meet strict regulations related to size, weight, and bounce, with organizations like the ITF overseeing standards. Manufacturers like Dunlop and Wilson are known for their high-performance balls, which are engineered for consistency and durability on various court surfaces.

In racquetball, the ball construction is crucial as it differs significantly from that of tennis. Racquetballs are typically made of rubber and have no felt covering; they are designed to bounce off walls and return quickly to the player. The manufacturing standards, though less regulated than tennis balls, focus on ensuring consistent bounce and speed, impacting how the game is played.

Lastly, footwear and apparel for both sports have seen significant advancements in production technologies. Tennis shoes are designed to offer lateral support due to the nature of the game, while racquetball shoes tend to be lighter with greater focus on grip to handle fast-paced movements on the court. Brands like Asics and Adidas have developed specialized lines catering to the unique requirements of each sport, showcasing their commitment to performance through innovation.

In conclusion, while racquetball and tennis are distinct sports with unique equipment needs, certain parallels exist in their manufacturing processes. The evolution of technology in materials, racquet design, and ancillary equipment manifests the dedication of manufacturers to enhance the player experience. Both sports benefit from ongoing research and development, contributing to a vibrant market that continues to evolve as athletes seek to improve their games. Whether on the court wielding a tennis racquet or a racquetball one, players can appreciate the advancements in equipment that allow them to perform at their best.

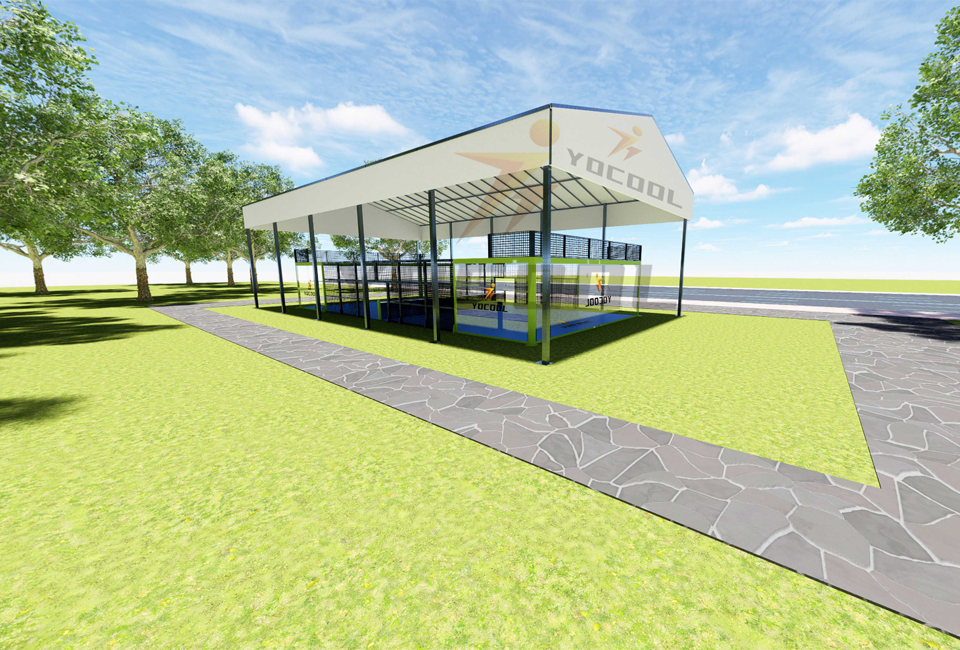

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions