The Evolution of Racquetball and Tennis Factories

Racquetball and tennis are two prominent racquet sports that have garnered substantial attention globally, leading to increased demand for specialized equipment. The factories that produce racquets, balls, and accessories for these sports have evolved significantly over the years, refining their techniques and technologies to meet the needs of both recreational players and professional athletes.

The Rise of Racquetball

Racquetball, while a relatively younger sport compared to tennis, emerged in the 1940s in the United States. Its popularity surged in the 1970s and 1980s, prompting manufacturers to innovate and produce high-quality equipment. Racquetball factories initially focused on wooden racquets, but as players’ preferences shifted towards lighter and more durable materials, manufacturers adapted by producing racquets made from aluminum, graphite, and other composite materials. This change allowed players to experience enhanced control, power, and maneuverability, fundamentally transforming the way the game was played.

Racquetball factories take into account various player preferences when designing racquets and balls. For instance, the balance, weight distribution, and grip size can be customized to enhance a player’s performance, making the manufacturing process quite intricate. Moreover, advances in computer-aided design (CAD) have enabled factories to simulate the performance of different materials and designs before physically producing them. This technology not only accelerates the production process but also ensures higher precision and quality in the final products.

The Tennis Boom

Similarly, the tennis industry witnessed a significant evolution over the decades. Tennis, with its origins dating back to the late 19th century, has developed into a global phenomenon. Factories producing tennis equipment have had to keep pace with the sport's growth, leading to innovations in racquet technology, string materials, and ball construction. The introduction of larger racquet heads, lighter materials, and improved string technology has transformed how players hit the ball, allowing for greater power and spin potential.

Tennis factories often utilize advanced methodologies such as 3D printing to prototype new racquets rapidly. This technology not only shortens the time it takes to design and test new products but also allows for customized solutions tailored to professional athletes who require specific specifications for optimal performance. Moreover, as sustainability becomes increasingly important in the manufacturing sector, factories are exploring eco-friendly materials and production processes to minimize their environmental impact.

The Intersection of Racquetball and Tennis Equipment Manufacturing

While racquetball and tennis may be distinct sports, their equipment manufacturing processes share several similarities. Both sectors benefit from advancements in materials science and engineering, as manufacturers continuously seek to find the perfect balance between performance, comfort, and durability. The factories often collaborate with professional players and coaches to gather feedback that directs their design choices, ensuring that the equipment meets the high standards of elite competition.

Additionally, marketing strategies in both industries focus on the importance of technology in enhancing player performance. Companies promote their products by highlighting innovations in material technology, customization options, and endorsements from professional athletes. This not only stimulates sales but also fosters a deeper connection between players and the equipment they use.

Conclusion

The factories producing racquetball and tennis equipment play a vital role in the evolution of these sports. Through innovation, adaptation, and a keen understanding of player needs, these manufacturing entities have significantly influenced how racquet sports are played today. As technology continues to evolve and sustainability remains a priority, the future of racquetball and tennis manufacturing will undoubtedly yield even more exciting advancements, ensuring that players at all levels can enjoy the dynamic and exhilarating nature of these sports.

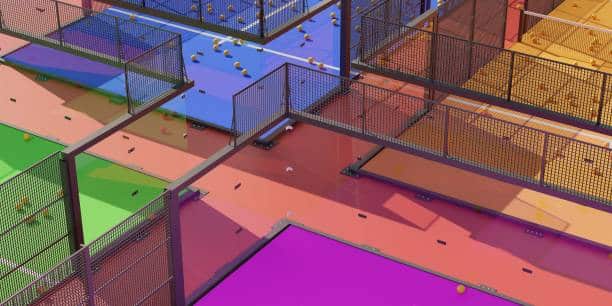

Durable Industrial Flooring Solutions for Factories & Padel Courts Custom

PVC Sports Flooring Durable, Shock-Absorbent & Safe

Premium Homogeneous Transparent Floor Durable, Slip-Resistant Rubber

Premium Rubber Composite Flooring Slip-Resistant & Durable

Premium Rubber Flooring Durable & Slip-Resistant Safety

Premium Rubber Brick Flooring - Durable, Eco & Slip-Resistant