The Rise of Paddle Factories A Look at the Growing Industry

In recent years, the sport of pickleball has surged in popularity, and along with it, the demand for high-quality paddles has skyrocketed. Paddle factories, dedicated to producing equipment specifically tailored for this fast-growing sport, are popping up across the globe. This article explores the factors driving the emergence of these factories, the technology behind paddle manufacturing, and the future landscape of the pickleball equipment industry.

The Rise of Paddle Factories A Look at the Growing Industry

One key aspect of paddle production is the variety of materials used in manufacturing. While wooden paddles were once the standard, modern factories now use composite materials, which offer superior performance and durability. These materials can include layers of fiberglass, polymer, and carbon fiber, each contributing to the paddle's weight, stiffness, and overall feel. Paddle manufacturers are constantly refining their techniques to strike the perfect balance between power and control, ensuring that players can make the most of their game.

Many paddle factories have also embraced technology to enhance their manufacturing processes. With the advent of computer-aided design (CAD) and three-dimensional printing, companies can prototype and test new paddle designs more efficiently than ever before. This technology allows for rapid iterations, enabling manufacturers to gather player feedback and refine their products in real time. The result is a continuous improvement loop that ensures paddles are not only innovative but also responsive to the needs and preferences of players.

Moreover, the role of branding and marketing in this evolving landscape cannot be underestimated. As competition increases in the paddle manufacturing space, factories are investing heavily in branding efforts to create a unique identity and build customer loyalty. This includes partnerships with professional players, sponsorship of tournaments, and engaging with the pickleball community through social media. By positioning their products as not just tools for sport but also lifestyle items, paddle brands can attract a broader audience.

Looking forward, the future of paddle manufacturing seems bright. As more people discover the joys of pickleball, the demand for paddles—both beginner and advanced—will only grow. This presents an opportunity for paddle factories to innovate further, focusing not only on performance but also on sustainability. With an increasing awareness of environmental issues, manufacturers may begin to explore eco-friendly materials and methods, setting a new standard for the industry.

In conclusion, the rise of paddle factories is a testament to the explosive growth of pickleball. As these factories continue to evolve, blending technology with craftsmanship, they will play a crucial role in shaping the future of the sport. For players, this means access to a wider variety of paddles, tailored to enhance their experience on the court. As the community continues to expand, the paddle manufacturing industry will undoubtedly find new ways to inspire and satisfy its diverse clientele.

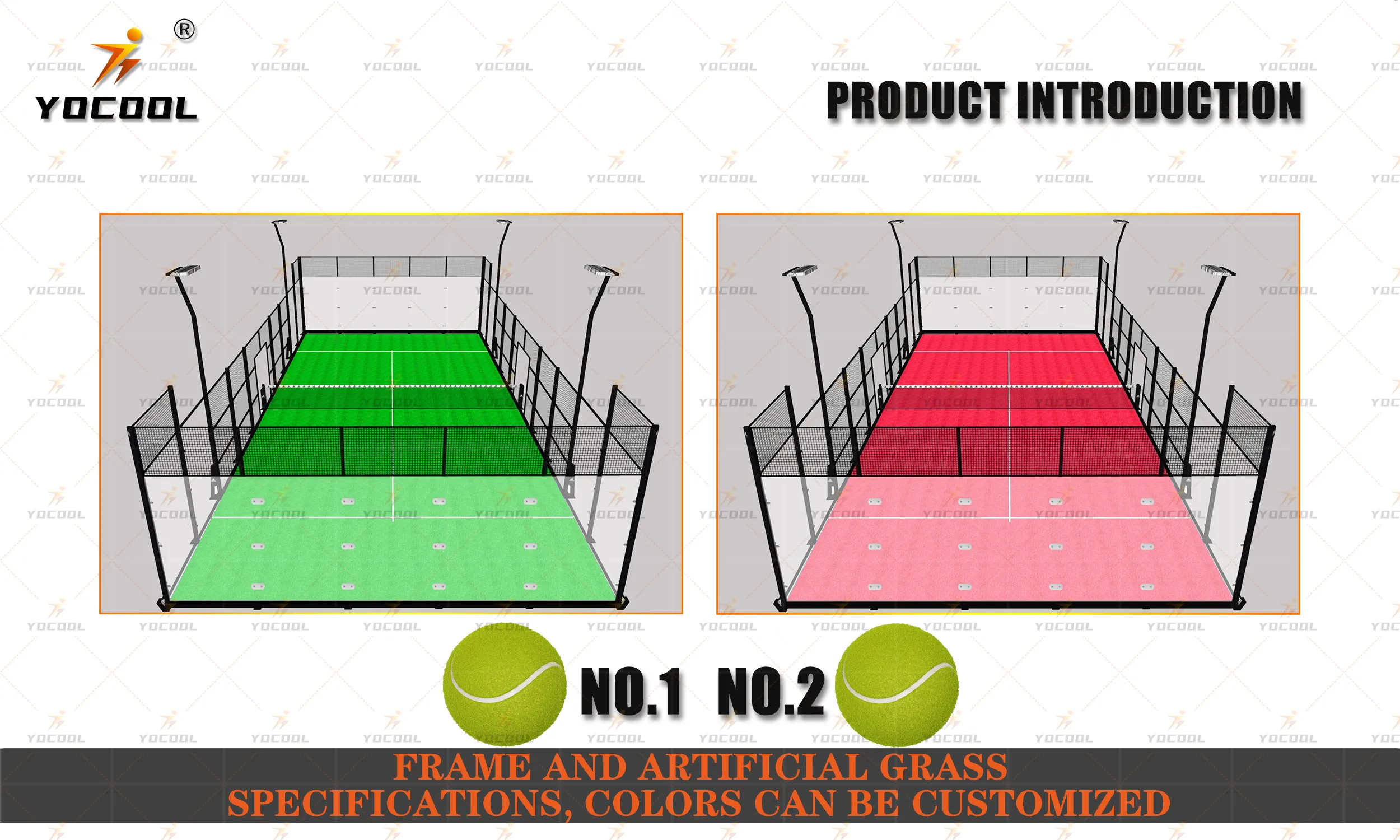

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions