The Rise of Padel Indoor Courts Factories and Their Role in a Growing Sport

Padel, a racket sport that combines elements of tennis and squash, has surged in popularity over the past decade. Originating in Mexico in the 1960s, it has now taken the world by storm, especially in Europe, where it has become a staple in recreational activity. As the demand for this engaging sport increases, so does the necessity for dedicated facilities. Indoor padel courts are at the forefront of this trend, and the factories that produce these courts play a crucial role in making this sport accessible to more players.

The Demand for Indoor Padel Facilities

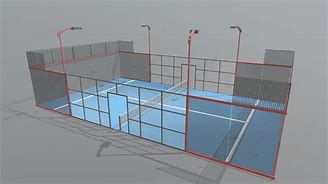

The growing popularity of padel can be attributed to its low barrier to entry, social nature, and the wonderful mix of strategy and athleticism. Unlike traditional tennis, padel is played on a smaller court enclosed by walls, which makes it more versatile regarding location and size. Consequently, many clubs, gyms, and private entities are looking to build indoor courts. This growing demand highlights the need for specialized factories that manufacture high-quality padel indoor court structures.

Indoor facilities provide several advantages over their outdoor counterparts. Weather can often be unpredictable, and indoor courts offer a guaranteed play environment, ensuring that players can enjoy their games year-round. Furthermore, geographical areas with cold winters or extreme heat can benefit significantly from these indoor complexes, allowing communities to engage in padel regardless of seasonal weather changes.

The Role of Factories in Padel Court Production

Factories that specialize in manufacturing indoor padel courts are pivotal in ensuring the sport's infrastructure keeps pace with its growth. The design and construction of these courts involve specialized materials and techniques that differ from traditional sports facilities. Factories invest in advanced technology and skilled labor to create courts that meet international standards.

1. Materials and Construction The manufacturers focus on high-quality materials such as tempered glass, aluminum, and synthetic flooring. Tempered glass walls provide excellent visibility and safety, while aluminum frames ensure durability. The flooring must be both resilient and provide the right amount of grip, thus enhancing players' performance and reducing the risk of injuries.

2. Customization Options Many factories offer customization services, allowing clubs to tailor the design of their courts to fit specific needs. This includes adaptations for size, color schemes, branding, and additional features like lighting systems and soundproofing. Such flexibility not only meets the aesthetic preferences of different venues but also optimizes the courts for varied climates and player experiences.

3. Sustainability Practices In recent years, many manufacturers have also embraced sustainability in their production processes. Factories integrate eco-friendly materials and practices, such as recycling unused materials and reducing waste during production. This not only lowers the environmental impact but resonates well with a growing segment of environmentally-conscious consumers and organizations.

Challenges Facing Manufacturers

While the market for padel courts is expanding, factories do face challenges that could affect their operations. Fluctuating raw material costs, supply chain issues, and labor shortages can impact production timelines and prices. Additionally, as the sport becomes more popular, the competition among manufacturers intensifies, requiring factories to innovate continuously and improve their offerings to stay ahead.

Moreover, consumer education is crucial. Many potential buyers are still unfamiliar with the specific requirements and benefits of high-quality indoor padel courts. Factories must engage in marketing efforts to educate clubs and investors about the value and significance of investing in properly constructed facilities.

The Future of Padel Indoor Courts

Looking forward, the outlook for indoor padel courts remains bright. With the rapid expansion of padel as a sport, particularly in regions like the United States and Asia, the need for more facilities is clear, signaling further growth for manufacturers. As urban areas become more populated, the demand for recreational spaces that are both accessible and multi-functional will likely drive investment in indoor padel courts.

In conclusion, as the popularity of padel continues to rise, the factories dedicated to producing indoor courts will play an essential role in the sport’s development. Through innovation, sustainable practices, and a commitment to quality, these manufacturers will not only support the growth of padel but also contribute to the creation of community spaces that foster health, social interaction, and enjoyment for players of all ages and skill levels. The humble indoor padel court is set to be a significant element in the sporting landscape of the future.

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions