The Cost of Building a Padel Court A Look into Factory Production

Padel, a sport that has gained remarkable popularity over the past few years, has seen a surge in the construction of dedicated courts. As the demand for padel courts increases, so does the necessity to understand the various factors that influence the cost of building these facilities, particularly when considering factory-produced elements.

Understanding Padel Courts

A standard padel court measures 20 meters in length and 10 meters in width, enclosed by walls composed of glass and solid panels. The proper design and construction of such courts require significant attention to detail to ensure safety and compliance with international federation standards. Given its unique attributes—like the use of walls as part of the gameplay—a well-built court can stand the test of time and offer an excellent experience for players.

The Role of Factory Production

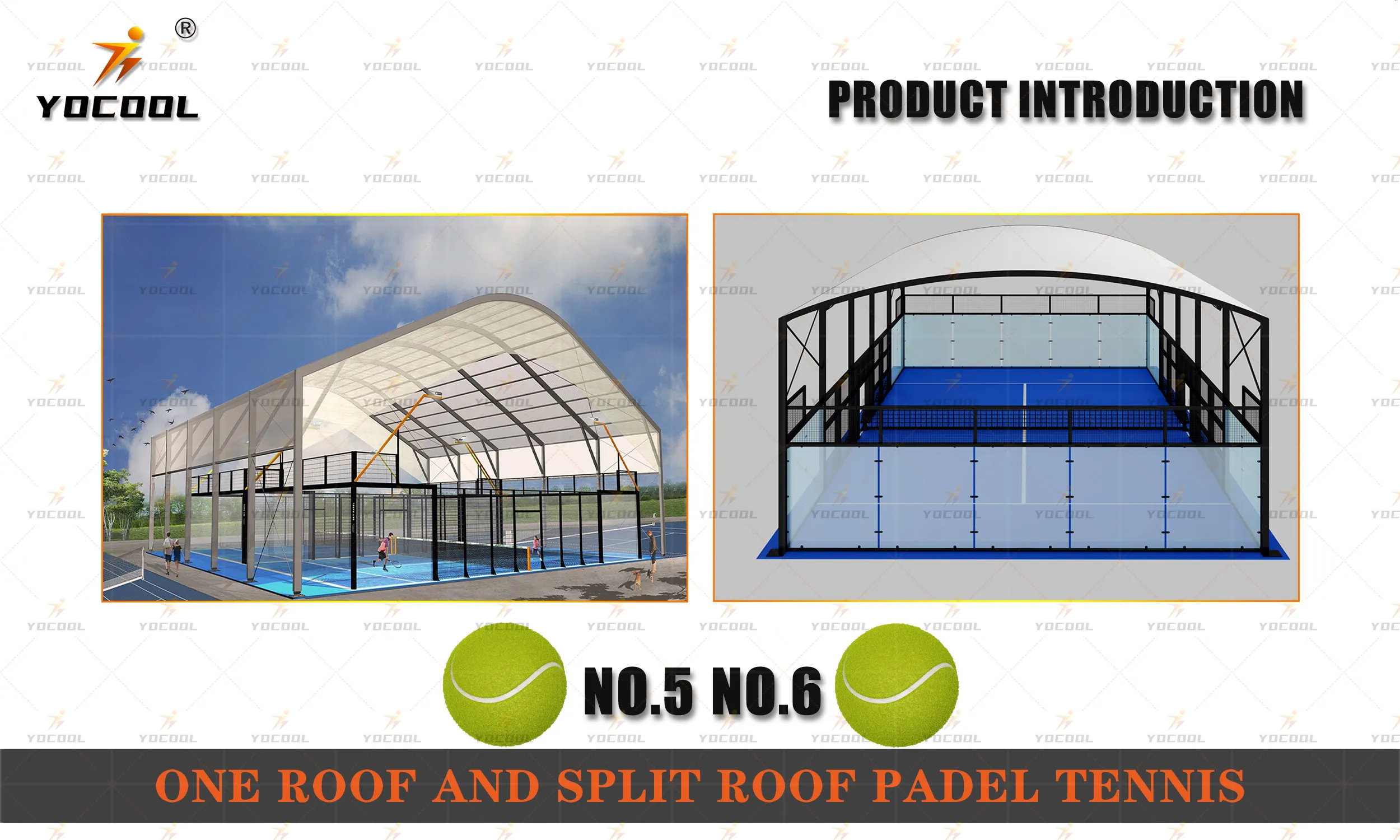

One significant aspect affecting the cost of building a padel court is whether components are fabricated in a factory or constructed on-site. Factory-produced elements, such as pre-fabricated panels and frames, often result in more streamlined construction processes. These factory settings employ advanced technology and machinery, ensuring precision and uniformity across components, which can significantly enhance the overall quality of the court.

When courts are built using factory-made materials, the costs might vary depending on a few key factors

1. Material Quality The choice of materials directly impacts both the durability of the court and the overall expenses. High-quality glass, for instance, provides better visibility and withstands impacts, albeit at a higher price.

2. Labor Costs Factory production can reduce labor costs significantly. Since the bulk of the work is completed in a controlled environment, the need for on-site labor is minimized. This can lead to savings on labor costs, which typically account for a substantial portion of the total expenses.

3. Customization and Features Adding special features such as lighting, seating areas, and spectator spaces can raise the cost. Factories can provide customized solutions, but these often come with additional expenses. The choice to include high-tech elements, such as automated scoreboards or advanced lighting systems, will further influence costs.

4. Transportation and Installation While factory production may lower initial costs, one must consider the logistics of transporting materials to the construction site. Depending on the distance from the factory, shipping fees can affect the overall budget. Additionally, installation might require specialized labor, adding to the costs.

Estimated Costs

While the total cost to build a padel court can range widely, it generally falls between $25,000 to $60,000, depending on the choices mentioned above. Courts that use factory-produced materials tend to be on the lower end of this spectrum due to reduced labor costs and time efficiency.

Conclusion

In summary, as the popularity of padel continues to grow, understanding the cost dynamics of building a court is essential for potential investors and sports enthusiasts alike. Factory production offers a viable solution, balancing quality and cost-effectiveness. By considering material choices, labor implications, and additional features, one can effectively navigate the expenses associated with constructing a padel court. Ultimately, investing in factory-manufactured components not only fosters quicker completion but can also enhance the overall quality and longevity of a padel facility.

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions