Understanding Padel Costs in Factory Production

Padel, a racquet sport that has been growing exponentially in popularity, combines elements of tennis and squash, played on an enclosed court. With its rising fame, manufacturers around the world are increasingly focusing on producing high-quality padel equipment, especially paddles and balls. Understanding the costs associated with padel production in factories can provide valuable insights for potential investors, manufacturers, and players alike.

The Components of Padel Production Costs

The cost of manufacturing padel equipment can be broken down into several key components

1. Raw Materials The quality of materials used is fundamental to the production of padel paddles. Typically, manufacturers source materials such as fiberglass, carbon fiber, and various forms of polymers. Each material has a different cost and greatly impacts the overall price of the paddle. High-performance materials, while more expensive, provide better durability and performance, appealing to competitive players.

2. Labor Costs The production of padel paddles often involves skilled labor, particularly in the crafting and finishing processes. Labor costs vary based on geographical location, with factories in countries with lower labor costs being able to produce paddles at a more competitive price. However, investing in skilled labor can lead to superior craftsmanship and higher-quality products.

3. Manufacturing Process The methods used in manufacturing can significantly affect costs. Advanced technology like CNC machining or automated assembly lines may require substantial initial investments but can reduce production costs in the long run. Additionally, the level of customization offered also plays a role—more tailored products typically require more time and resources, raising costs.

4. Research and Development (R&D) As the sport evolves, so does the technology behind padel equipment. Companies often invest heavily in R&D to develop new designs and technologies that enhance performance. While these investments can be substantial, they are crucial for maintaining competitiveness in the market.

5. Marketing and Distribution Once produced, products must reach consumers. This involves marketing strategies, distribution channels, and retail partnerships. The costs associated with branding, advertising, and logistics can significantly impact the final price of the product.

The Impact of Current Trends

The padel market is witnessing various trends that can influence production costs. The rise of eco-conscious consumers is motivating manufacturers to consider sustainable practices, which may initially increase costs but, in the long run, can lead to a more loyal customer base. Additionally, the increasing popularity of padel in regions such as North America and Asia is prompting factories to ramp up production, which could lead to economies of scale and lower unit costs.

Conclusion

In conclusion, understanding the costs associated with factory production of padel equipment is essential for anyone involved in this rapidly growing industry. From raw materials to labor and manufacturing processes, each factor contributes to the overall expense of creating high-quality padel paddles. As the sport continues to develop and attract a larger audience, manufacturers must navigate these costs effectively to remain competitive while also meeting the demands of consumers. With the right strategies, companies can produce exceptional padel equipment that not only enhances the game but also contributes to the sport's ongoing growth.

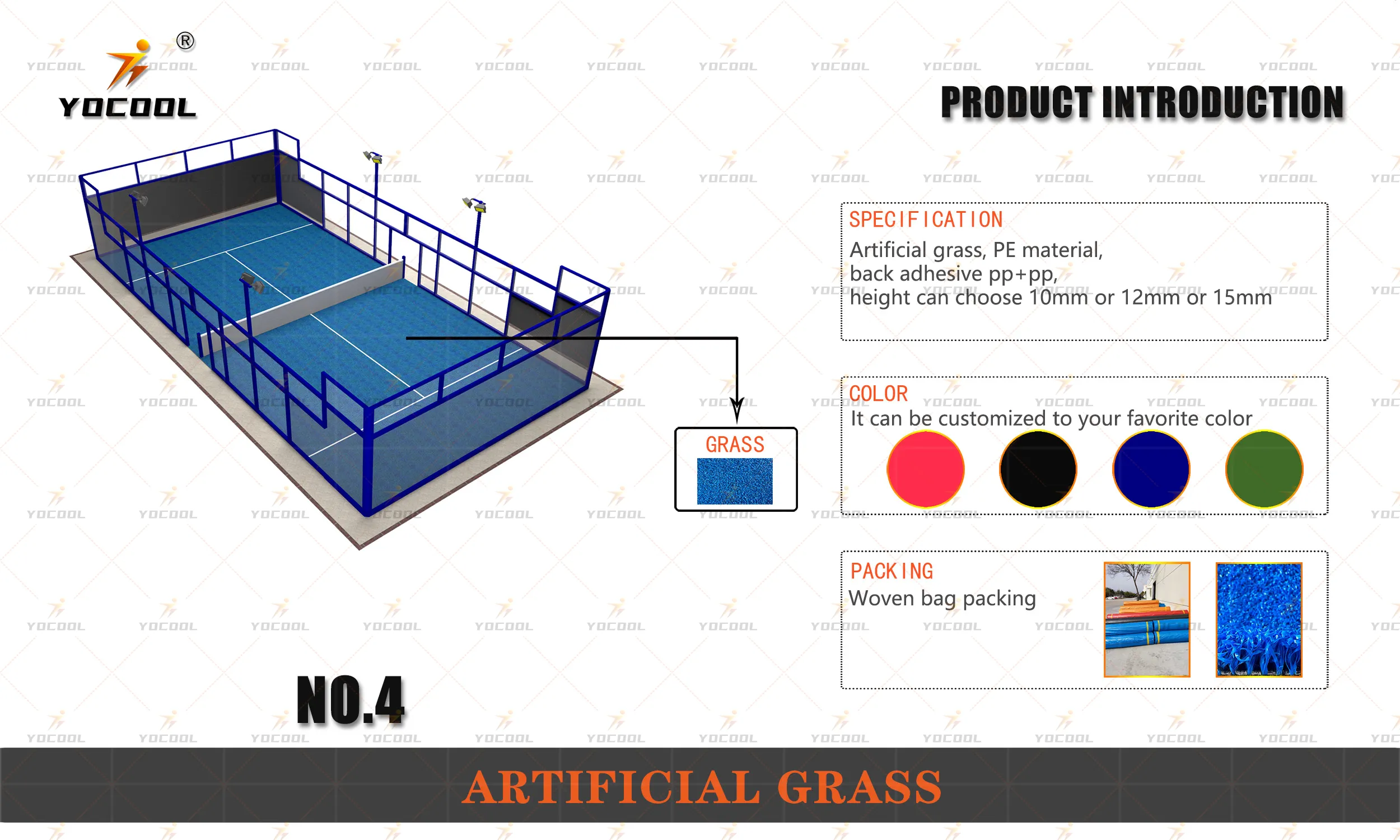

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions