Understanding Padel Cost An Insight into the Padel Factory

Padel has emerged as one of the fastest-growing sports worldwide, attracting players of all ages and skill levels. As enthusiasm for this racquet sport grows, so does the need for high-quality equipment. One of the key factors contributing to the accessibility of this sport is the cost associated with manufacturing padel equipment. This article delves into the various factors affecting padel costs and the role of factories in the production process.

1. The Components of Padel Equipment

Padel sports primarily require three essential pieces of equipment racquets, balls, and court facilities. Each of these components comes with a unique cost structure that comes from various materials, manufacturing processes, and quality assurances.

Padel Racquets The cost of producing a padel racquet largely depends on the materials used, such as carbon fiber, fiberglass, and foam for the core. High-performance racquets are made from premium materials, resulting in higher production costs. Factories typically source these materials in bulk to maximize efficiency and minimize costs. This ensures that the final product is both durable and performance-oriented.

Padel Balls The construction of padel balls involves rubber, felt, and other materials that ensure optimal performance on the court. Manufacturing companies must follow strict regulations for ball pressure and consistency, which can add to the production costs. While cheaper variants exist, professional-grade balls with longer durability and better bounce are often pricier.

Court Construction One of the significant expenses in promoting padel is the construction of courts. The cost is influenced by land prices, construction materials, and maintenance. Standard padel courts require specific dimensions and surfaces (usually made from artificial turf), which contributes to the overall setup cost.

2

. Manufacturing ProcessThe production of padel equipment typically involves assembly lines where factories utilize modern technology to optimize efficiency. Automation plays a significant role in reducing labor costs, but skilled labor is still essential at various stages, particularly when it comes to quality control.

Factories often operate under international regulations, ensuring that products meet required standards across different markets. This compliance entails additional testing and certification, which can elevate costs, but it significantly enhances the trustworthiness of the product.

3. Price Variances and Market Trends

Prices for padel equipment can vary widely based on brand prestige, material quality, and manufacturing location. Some factories offer budget-friendly options, while others cater to professional-level athletes with state-of-the-art gear. As the popularity of padel grows, brands find themselves in a competitive market, leading to promotions and pricing strategies that benefit consumers.

Conclusion

In summary, the costs associated with padel equipment are influenced by several factors, including material quality, manufacturing processes, and market demands. As factories continue to innovate and adapt to the growing demand for padel, players can expect a wider variety of products at different price points. Ultimately, understanding the complexities of these costs can help consumers make informed choices and contribute to the ongoing development of the sport. The future of padel looks promising, with more accessibility and a broader reach across various demographics, thanks to the effective strategies adopted within the manufacturing sector.

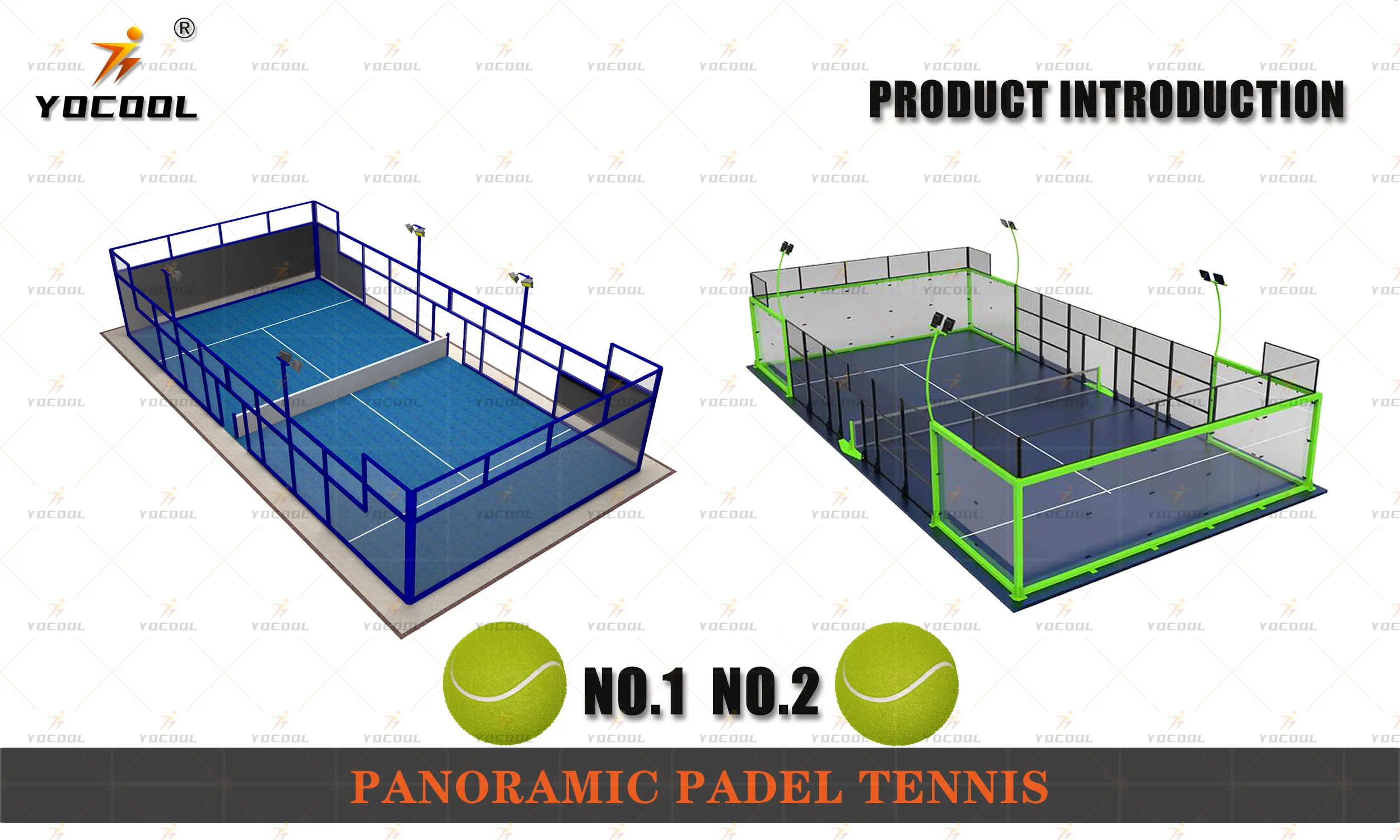

High-Quality Padel Court Solutions for Sports Facilities & Clubs

Premium Padel Courts: Custom Designs & Panoramic Views

Premium Paddle Racquet | High-Control Lightweight Design

NO.2 Panoramic Padel Orange Racket - Superior Grip & Durability

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective