The World of Paddle Tennis Racket Factories

Paddle tennis, a popular racquet sport that combines elements of tennis and squash, has gained significant traction in recent years. Its unique playing experience, played on smaller courts and with solid rackets, attracts players of all ages. At the heart of this burgeoning sport lies the factories that manufacture paddle tennis rackets. These facilities are not only pivotal in producing high-quality equipment but also play a crucial role in the evolution of the game.

The Manufacturing Process

The production of paddle tennis rackets involves several intricate processes that ensure the final product meets the demands of players. Most racket factories employ advanced technology and skilled craftsmanship to ensure quality and performance. The journey begins with material selection. Common materials used include composite fiberglass, carbon fiber, and polymer foam. Each type of material offers different properties like weight, durability, and power, which affect the racket's performance on the court.

Once the materials are chosen, the manufacturing process starts with the core. The core of a paddle racket is crucial as it significantly influences its feel and responsiveness. Foam or polymer composites are typically used to create the core, providing an excellent balance between resilience and control. The core is then sandwiched between layers of fiberglass or carbon fiber, which contribute to the racket's overall strength and stability.

After constructing the core and frame, the rackets move on to the finishing stage. This involves sanding, painting, and applying a protective coating to ensure longevity. Many manufacturers employ stunning designs and vibrant colors to make their products appealing to players. This aspect of production is essential, as the aesthetic appeal of a racket can play a significant role in a player's purchase decision.

The Role of Technology

Modern paddle tennis racket factories leverage advanced technology throughout the manufacturing process. Computer numerical control (CNC) machines play a vital role in ensuring precision during the cutting and shaping of racket components. This automation helps maintain consistency in product quality while reducing production times.

Furthermore, 3D printing technology is increasingly being utilized in prototype development. Manufacturers can quickly produce racket prototypes, allowing for more efficient testing and refinement before mass production. This iterative design process helps companies innovate and meet the evolving preferences of players.

Sustainability Initiatives

As awareness of environmental issues grows, many paddle tennis racket factories are adopting sustainable practices. From sourcing eco-friendly materials to implementing energy-efficient manufacturing processes, these initiatives aim to reduce the industry's carbon footprint. Some factories are even experimenting with biodegradable materials for racket production, recognizing the importance of protecting the environment while serving a passionate community of athletes.

Market Trends and Innovations

The paddle tennis racket industry is continuously evolving, driven by changing consumer preferences and advancements in technology. One notable trend is the customization of rackets. Many manufacturers now offer players the option to personalize their rackets in terms of design, weight balance, and grip size. This personalization not only enhances player performance but also allows individuals to express their unique playing styles.

Another exciting development is the integration of smart technology into paddle tennis rackets. Some modern rackets now come equipped with sensors that track player performance metrics such as swing speed, shot accuracy, and impact pressure. This data can be invaluable for players looking to improve their skills and gain a competitive edge.

The Global Landscape

The global market for paddle tennis rackets is expanding, with factories located in various countries, including the United States, Spain, and Argentina. Each region tends to have its unique approach to manufacturing, influenced by local traditions and player preferences. As the sport grows in popularity, particularly in Europe and Latin America, the demand for high-quality rackets continues to rise, prompting factories to increase their production capacity.

Conclusion

Paddle tennis racket factories are at the forefront of the sport's evolution, continually adapting to technological advancements and player demands. Through intricate manufacturing processes, innovative designs, and a commitment to sustainability, these factories are shaping the future of paddle tennis. As the sport continues to gain momentum worldwide, the role of these factories will remain crucial in providing players with the equipment they need to excel on the court. Whether you're a seasoned player or a newcomer to the game, understanding the craftsmanship behind your paddle tennis racket can deepen your appreciation for this fast-paced and exhilarating sport.

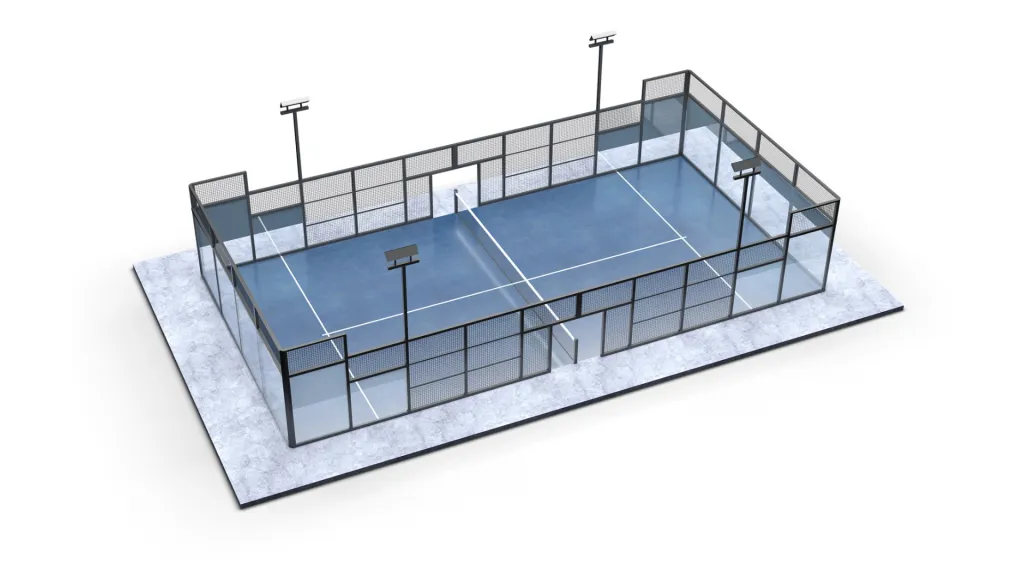

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions