The Rise of Paddle Tennis A Look at Paddle Tennis Fields and Factories

Paddle tennis is a sport that has gained immense popularity in recent years, offering an exciting blend of tennis and squash, appealing to both recreational players and serious athletes alike. As the demand for paddle tennis continues to grow, the need for specialized facilities and manufacturing capabilities is on the rise. This article delves into the evolution of paddle tennis fields and the factories that produce the necessary equipment, highlighting the importance of quality construction and innovation in this burgeoning sport.

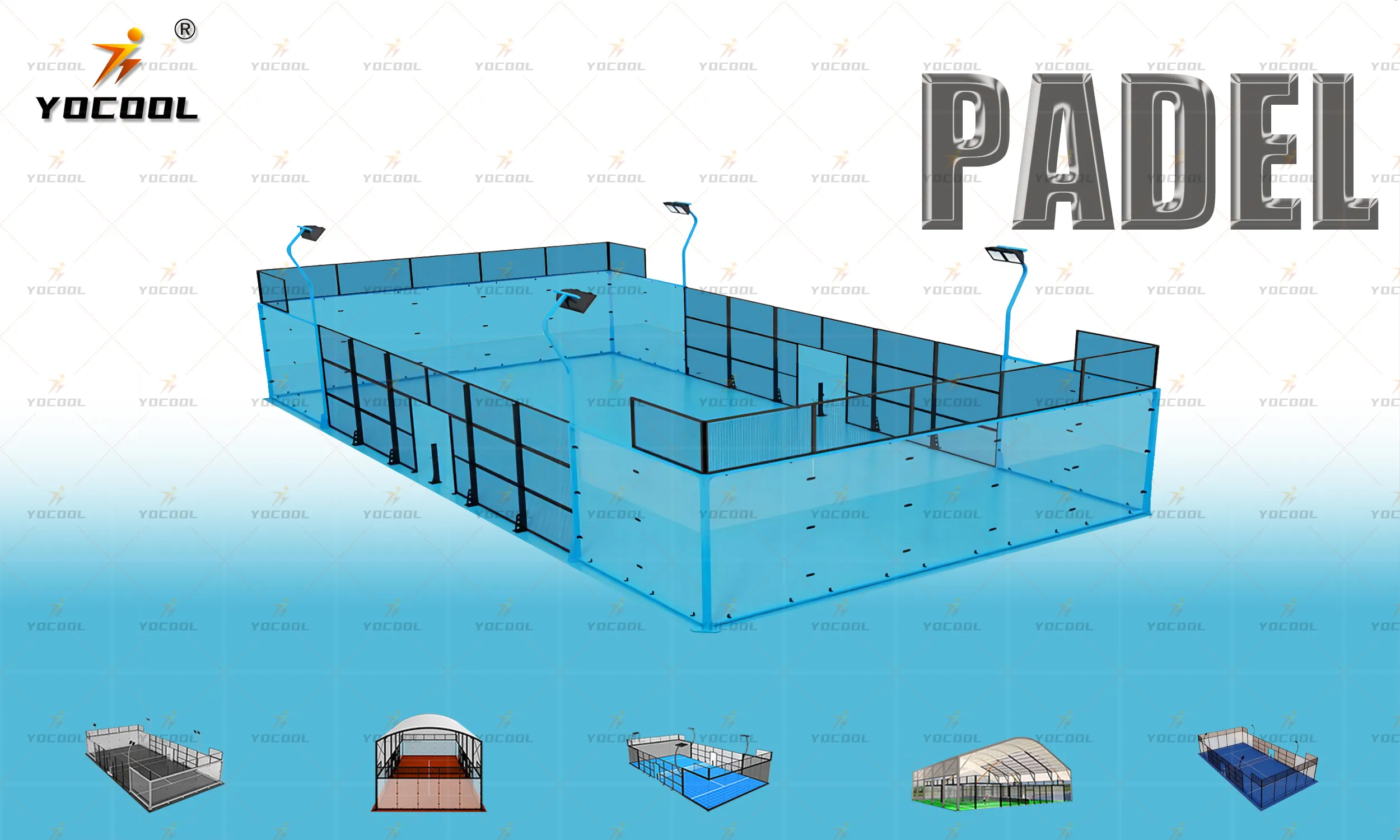

Paddle tennis courts are distinctively designed to accommodate the unique dynamics of the game. Unlike traditional tennis courts, paddle tennis courts are smaller, typically measuring 20 meters long and 10 meters wide. They are enclosed by glass walls and wire mesh, allowing for optimal ball rebound and creating an immersive environment for players. The surface material also differs, as it often features artificial grass or an acrylic surface designed to provide the right balance of traction and cushioning.

The Rise of Paddle Tennis A Look at Paddle Tennis Fields and Factories

As the number of paddle tennis courts increases, so does the need for factories that specialize in the production of paddle tennis equipment. These factories are tasked with manufacturing high-quality paddles, balls, and net systems designed specifically for the demands of paddle tennis. The evolution of technology in sports manufacturing has greatly influenced the design and durability of paddle tennis equipment. Modern factories employ advanced materials and techniques to produce innovative products that enhance player performance and ensure longevity.

Paddle tennis paddles, for instance, are crafted from a variety of materials, including composite, fiberglass, and carbon fiber. Each material offers different advantages in terms of weight, power, and control. Factories are constantly researching and developing new materials and designs to provide players with the most effective and comfortable equipment. The design includes features such as grip texture for better handling and unique shape for improved aerodynamics.

Additionally, the balls used in paddle tennis are specifically designed to fit the style of play. Unlike traditional tennis balls, paddle tennis balls are slightly smaller and feature less pressure, allowing for better control and manipulation of the game. Factories recognize the importance of consistency and quality in production, ensuring that every ball meets the established standards for durability and playability.

Another critical aspect of paddle tennis factories is their commitment to sustainability. As the global conversation around environmental responsibility continues to evolve, many manufacturers are integrating eco-friendly practices into their operations. This includes sourcing sustainable materials for equipment and implementing recycling programs, ensuring that paddle tennis can thrive in a way that is conscious of its environmental impact.

In conclusion, the growth of paddle tennis has sparked a significant expansion in paddle tennis fields and manufacturing capabilities. As communities continue to embrace this dynamic sport, the construction of courts and the production of high-quality equipment will only increase. Factories dedicated to paddle tennis will play a pivotal role in shaping the future of the sport, focusing on innovation, quality, and sustainability to provide players with the best experience possible. Paddle tennis is not just a sport; it is a thriving industry, and its trajectory looks promising as it continues to capture the hearts of players around the world.

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions