The Art of Crafting Paddle Racquets A Journey into the Paddle Racquet Factory

In the world of sports, few activities offer as much enjoyment and exercise as paddle racquet sports. From pickleball to padel, these games have gained immense popularity, captivating players with their fast-paced action and social dynamics. However, behind the scenes of this thriving industry lies a meticulous process that brings paddle racquets to life—a journey into the paddle racquet factory.

The Design Phase

Every remarkable paddle racquet begins with a concept. Designers and engineers in the factory collaborate to create racquets that balance power, control, and comfort. They study various factors such as weight distribution, grip size, and material composition. Modern paddle racquets are typically made from advanced materials like carbon fiber, fiberglass, and foam for the core, offering players enhanced performance and durability. This stage requires a fusion of creativity and technical knowledge, as the team balances aesthetics with functionality.

Material Selection

Once the design is finalized, the next step involves sourcing high-quality materials. The paddle racquet factory works closely with suppliers to acquire the best carbon fibers, foams, and other essential components. Sustainability has also become a priority for many factories, leading them to explore eco-friendly materials and manufacturing processes. This commitment not only addresses environmental concerns but also appeals to a growing consumer base that values sustainable practices.

Manufacturing Process

After material selection, the manufacturing process begins. It is a blend of tradition and modern technology. Each paddle racquet is crafted through a series of intricate steps. The outer frame is molded, and the core is shaped to ensure optimal performance. This stage often involves precision machinery and skilled craftsmanship to achieve the desired specifications. The factory employs workers who bring years of experience to the table, ensuring that each racquet meets rigorous quality standards.

Quality Control

Quality control is paramount in the paddle racquet manufacturing process. Each finished racquet undergoes a series of tests to verify its durability, weight, and balance. This stage is crucial; a well-designed racquet that doesn't pass quality checks can lead to disappointing experiences on the court. The factory's quality assurance team meticulously inspects the racquets, ensuring they perform flawlessly. Attention to detail during this stage reinforces the factory's commitment to excellence.

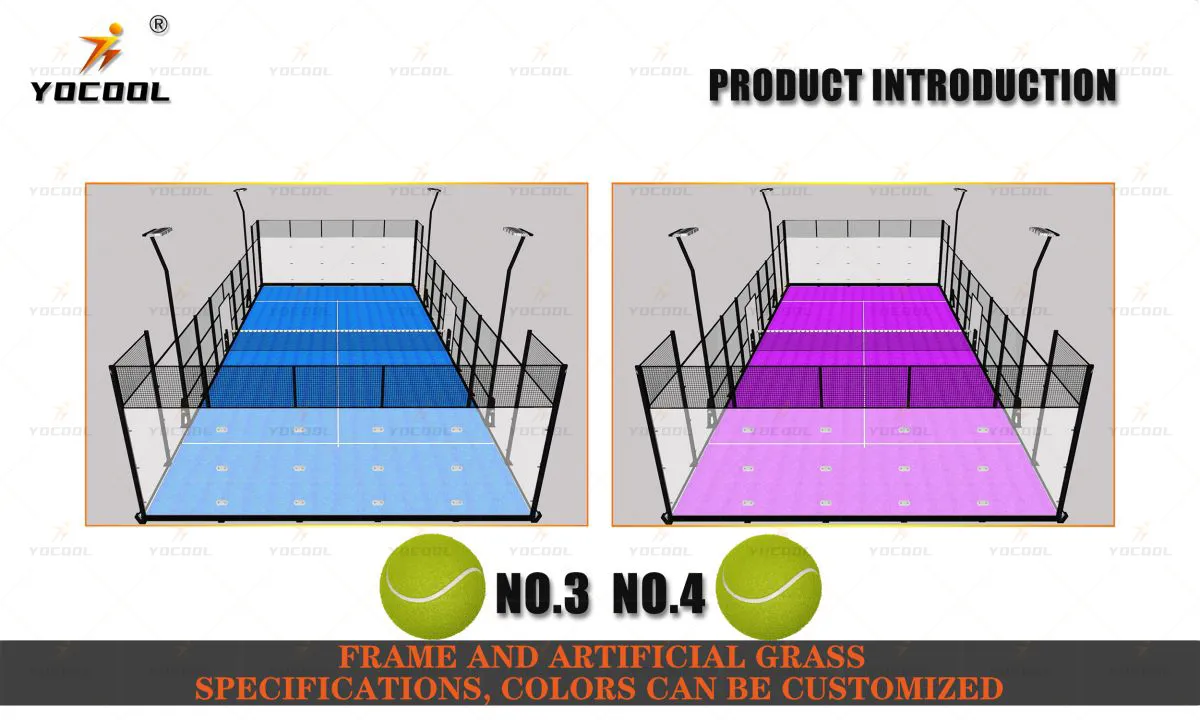

Customization Options

In recent years, the demand for customization in paddle sports has soared. Many factories now offer personalized options, allowing players to choose specific features such as color schemes, grip sizes, and even custom logos. This element of personalization not only enhances the player's experience but also fosters a sense of ownership and pride in the equipment they use.

Distribution and Marketing

Once the paddle racquets are completed and pass quality assessments, they are packaged and prepared for distribution. The factory collaborates with retailers and sports brands to bring these racquets to market. Leveraging both traditional advertising and social media, marketing teams craft campaigns that highlight the unique features and benefits of their products. Influencer partnerships and sponsorships also play a significant role in promoting racquet sports and the equipment that enhances the games.

A Community of Passionate Players

Ultimately, the paddle racquet factory is more than a production facility; it is a hub of innovation and passion for the sport. Each racquet that rolls off the assembly line represents countless hours of design, craftsmanship, and dedication. As players take to the courts, they carry with them a piece of this journey, enhancing their game while enjoying the camaraderie of paddle sports.

The paddle racquet factory embodies the spirit of sportsmanship, sustainability, and community. Whether you are a novice just beginning your paddle journey or a seasoned player competing at a high level, the hard work and commitment of those who create these racquets ensure that every match is an experience to remember.

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions