The Evolution of Paddle Racquet Factories Innovation and Craftsmanship

In recent years, the sports industry has witnessed a remarkable surge in the popularity of paddle sports, particularly padel and pickleball. This growing trend has catalyzed the development of specialized paddle racquet factories, where innovation meets craftsmanship. These factories have transformed the landscape of paddle sports equipment, catering to players of all levels with precision-engineered racquets designed for optimal performance and durability.

The journey of paddle racquet manufacturing began with traditional craftsmanship, where skilled artisans hand-crafted racquets using wood and other natural materials. These early racquets provided a basic level of performance but were limited in terms of technology and design. As the demand for paddle sports grew, particularly in Europe and North America, the industry began to embrace modern manufacturing techniques. This shift marked the emergence of paddle racquet factories that prioritized advanced materials and innovative designs.

One of the most significant advancements in paddle racquet manufacturing has been the incorporation of composite materials. Factories now utilize a blend of carbon fiber, fiberglass, and foam cores to create lightweight yet sturdy racquets. This combination not only enhances performance but also provides players with a greater sense of control and power during gameplay. The use of computer-aided design (CAD) and cutting-edge manufacturing processes has allowed factories to produce racquets that are tailored to specific playing styles, ensuring that every player can find a perfect fit.

Moreover, paddle racquet factories have invested heavily in research and development (R&D) to stay ahead of the competition. Engineers and designers collaborate to experiment with various shapes, weights, and grip styles, leading to the creation of specialized racquets for different skill levels—ranging from beginners to professionals. Customization options have also become a hallmark of modern paddle racquet manufacturing, with players now able to choose personalized features that reflect their unique preferences and playing habits.

Sustainability has become a guiding principle for many paddle racquet factories as environmental concerns rise globally. Manufacturers are adopting eco-friendly practices by sourcing sustainable materials and implementing energy-efficient production methods. This commitment to sustainability not only attracts environmentally-conscious customers but also sets a new standard within the industry.

Additionally, the global expansion of paddle sports has encouraged factories to diversify their offerings. Many brands now produce a range of complementary equipment, including bags, balls, and apparel, creating a comprehensive ecosystem for paddle enthusiasts. This diversification not only enhances brand loyalty but also fosters a vibrant community around paddle sports.

Looking ahead, the future of paddle racquet factories appears bright. As advances in technology continue to reshape manufacturing processes, players can expect even greater innovations in racquet design and performance. From enhanced aerodynamics to smart racquets embedded with technology that tracks performance metrics, the possibilities are endless.

In conclusion, paddle racquet factories play a pivotal role in the evolution of paddle sports. They combine the rich tradition of craftsmanship with modern technology to produce exceptional equipment that enhances the playing experience. As the popularity of paddle sports continues to grow, these factories will undoubtedly play a crucial part in shaping the future of the industry, combining innovation, sustainability, and unparalleled performance.

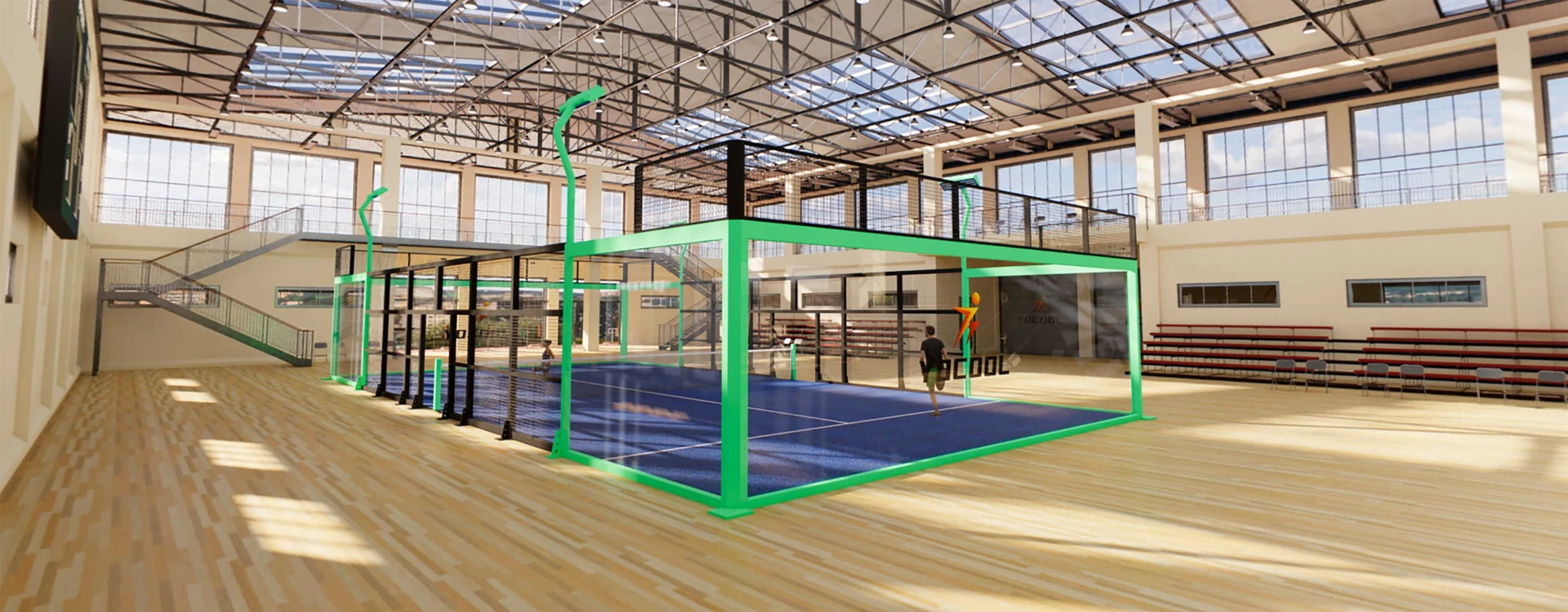

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions