The Importance of Paddle Production in Tennis Factories

In recent years, the sport of tennis has witnessed a significant surge in popularity, leading to an increase in demand for high-quality gear. Among the critical components in a player’s arsenal is the tennis paddle, a piece of equipment that directly impacts performance on the court. Tennis factories, which produce these paddles, play a vital role in ensuring that players have access to top-tier equipment that meets the needs of both amateur and professional athletes.

Paddle production in tennis factories involves a meticulous process that requires a blend of craftsmanship, technology, and quality control. High-quality paddles are typically made from advanced materials such as carbon fiber and composite materials, which enhance durability and performance. The manufacturing process begins with the selection of the right materials, where factors such as weight, strength, and flexibility are taken into consideration.

The Importance of Paddle Production in Tennis Factories

After shaping, the next critical phase is applying the finish to the paddle. This can involve painting, coating, or adding grips to ensure that the paddle is not only visually appealing but also comfortable and functional. A well-finished paddle can enhance a player’s grip and control, making this stage pivotal for overall performance.

Quality control is a cornerstone of paddle production in tennis factories. Before any paddle reaches the hands of consumers, it undergoes rigorous testing to ensure that it meets set performance standards. This includes testing for durability, balance, and responsiveness. Factories understand that even the smallest defect can significantly affect a player’s game, which is why maintaining high standards is non-negotiable.

Furthermore, advancements in technology have revolutionized paddle production. Innovations such as computer-aided design (CAD) software allow manufacturers to create precise paddle designs that can be tested digitally before physical production begins. This not only enhances efficiency but also minimizes material waste, contributing to more sustainable manufacturing practices.

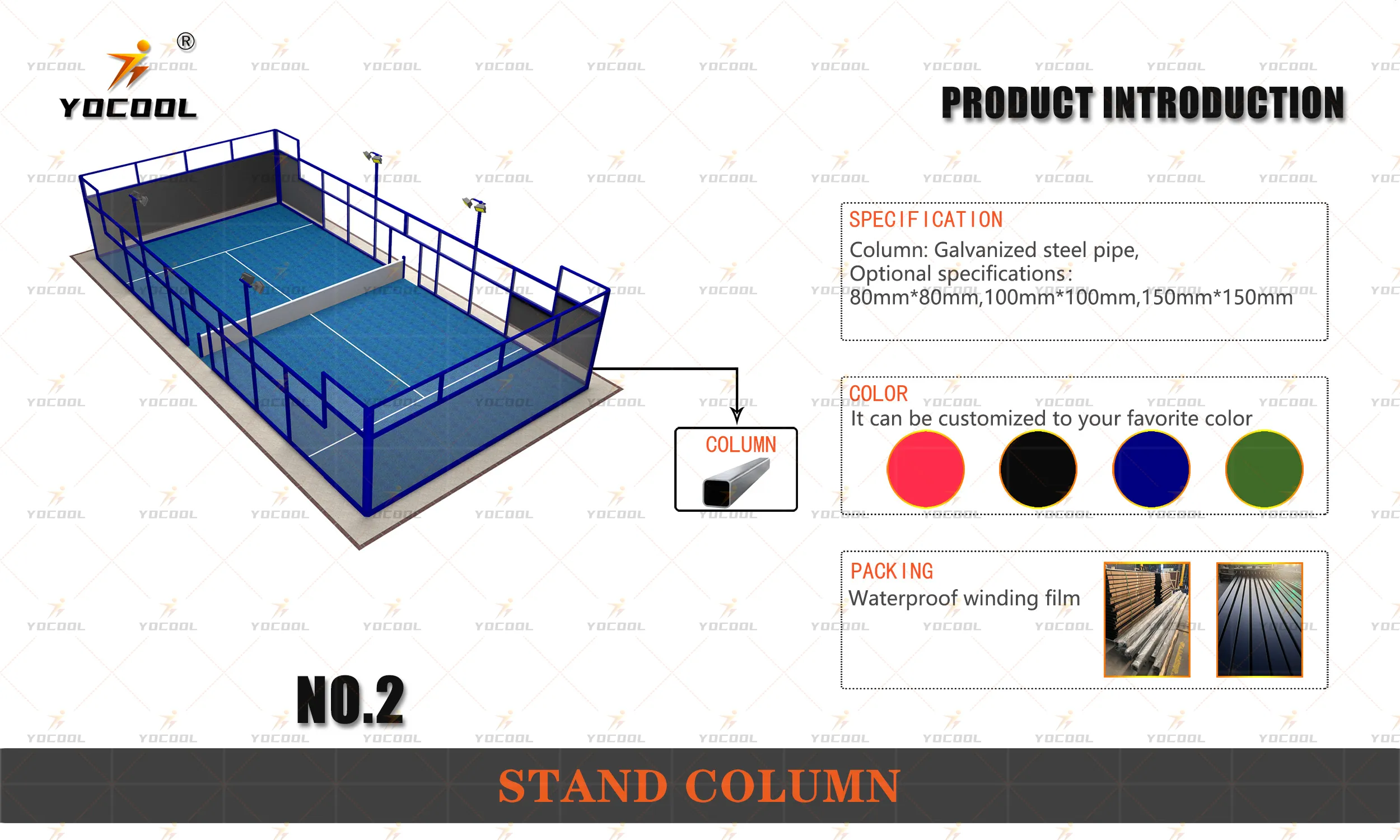

Another aspect worth noting is the importance of customization in paddle production. Many players opt for personalized paddles that reflect their individual style and preferences. Tennis factories are increasingly offering customization options, allowing players to select not only the size and weight of the paddle but also colors and designs. This trend has become particularly popular among younger players, who value individuality and personal expression in their sporting gear.

In conclusion, paddle production in tennis factories is a complex and multifaceted process that plays a crucial role in the growth and development of the sport. The commitment to quality, innovation, and customization ensures that players have access to equipment that enhances their game and reflects their unique style. As tennis continues to evolve, so too does the technology and methods used in paddle production, promising exciting advancements for both players and manufacturers alike.

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions