International Squash Court Factories Building the Future of Squash

Squash is a fast-paced and dynamic sport that has gained tremendous popularity around the world. As participation increases, the demand for high-quality squash courts has also risen. This surge in interest leads us to the role of international squash court factories, which are pivotal in creating facilities that meet the unique requirements of this sport.

The essence of a squash court lies not only in its design but also in the materials and construction methods utilized. International squash court factories focus on producing courts that comply with the standards set by the World Squash Federation (WSF). These standards ensure that courts provide the best possible conditions for players, from amateur enthusiasts to elite professionals.

Modern squash courts are designed with several key considerations in mind. The playing surface is crucial; it must offer sufficient grip while minimizing the risk of injury. Leading factories employ advanced technologies and incorporate materials such as maple or oak hardwood for flooring, as these woods provide the right balance of hardness and cushioning. Additionally, the walls of the court are often made of specialized glass or acrylic to facilitate visibility and allow for natural light, enhancing the overall playing experience.

Another significant element is acoustic design, which aims to minimize sound reverberation within the court. This feature is essential not only for a pleasant playing atmosphere but also for ensuring that players can communicate clearly during matches without distractions from echoes. Factories proficient in this domain employ sound-absorbing materials strategically to achieve optimal acoustics.

Moreover, international squash court factories prioritize sustainability by implementing eco-friendly practices in their manufacturing processes. This commitment to sustainability may involve using recycled materials, reducing waste, and employing energy-efficient technologies. As the global community becomes more conscious of environmental issues, these practices set manufacturers apart and cater to clients who value sustainability alongside performance.

In addition to constructing new courts, international squash court factories often offer refurbishment services. Many existing courts are in need of upgrades to comply with contemporary standards or to enhance player comfort. Refurbishment can include replacing worn-out surfaces, updating lighting systems, installing advanced wall materials, and improving ventilation to ensure an optimal playing environment.

Moreover, international squash court factories often engage in partnerships with sports organizations and clubs to help them design and build facilities that cater to their specific needs. Customization options allow clubs to create unique spaces that enhance their community’s squash experience, further promoting the sport’s growth.

In conclusion, international squash court factories play a critical role in the sport’s evolution. From the manufacturing of new courts to refurbishment and sustainability efforts, these factories ensure that players have access to world-class facilities. As squash continues to grow in popularity, the commitment of these factories to innovation and excellence will undoubtedly help shape the future of the game, creating more opportunities for players at all levels to enjoy and excel in this exhilarating sport. With the right courts, the sky's the limit for squash enthusiasts around the globe.

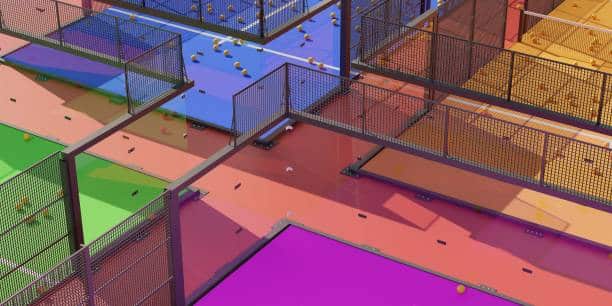

High-Performance Industrial Flooring Solutions China Paddle Tennis Court for Sale

High-Performance Industrial Flooring Solutions Durable & Cost-Effective

Homogeneous Transparent Floor – Durable & Stylish Rubber Floor Solutions

Premium Homogeneous Transparent Floor for Durable & Stylish Spaces Rubber Floor Solutions

Premium Sports Floor Solutions Durable PVC Sports Floor & Rubber Floor for Gyms

Durable Rubber Composite Floor Premium Rubber Floor & Mats Solutions